duanegeib

Member

- Joined

- Feb 27, 2017

- Messages

- 23

- Location

- USA

- Vessel Name

- Journey

- Vessel Make

- 1987 Jefferson 42 Sundeck

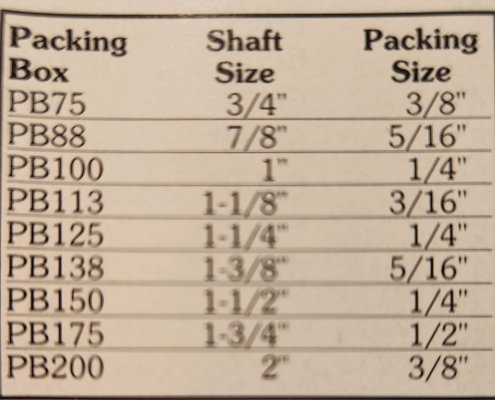

Here is a picture of my propeller shaft and stuffing box. I have two questions. The first question is, Does anyone know the type of maker of the stuffing box. I have researched extensively about repacking it, but would like to find the maker so I can research it before i endeavor to repack it. I would be doing it while in the water.

Second question. The metal strap touching my prop shaft. Is it to ground the propeller. Notice it is attached to a green wire and then touches the prop shaft. I need to replace it. What type of metal would I buy to replace it.

Second question. The metal strap touching my prop shaft. Is it to ground the propeller. Notice it is attached to a green wire and then touches the prop shaft. I need to replace it. What type of metal would I buy to replace it.