LeoKa

Guru

- Joined

- Apr 15, 2017

- Messages

- 1,169

- Location

- USA

- Vessel Name

- Ironsides

- Vessel Make

- 54' Bruce Roberts steel sailboat hull, coastal LRC, 220HP CAT 3306.

I need advice, or opinion, on an idea, which was recommended to me by a friend. His engine died on anchor and could not pull the anchor up to move.

He is thinking about a generator hydraulic backup solution.

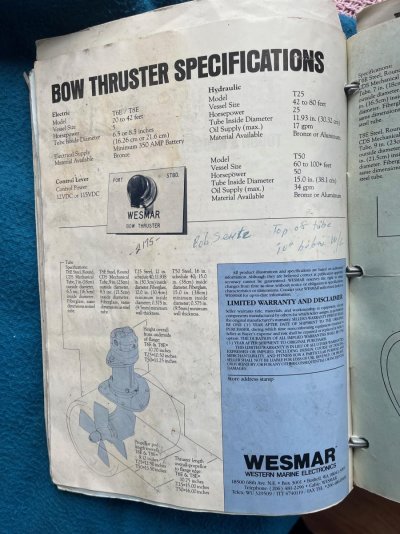

Since I also have hydraulic steering, windlass, autopilot, I would not mind a backup solution for emergencies. I have replaced most of the hydraulic system I have a couple years ago. My hydraulic pump is on the main engine and handles the bow thruster and the windlass. The steering hydraulics is a separate setup with the autopilot. Even if I do not care about steering, I do need the anchor to be pulled up in all cases.

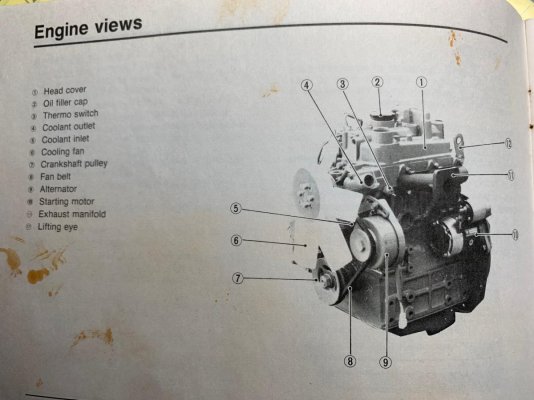

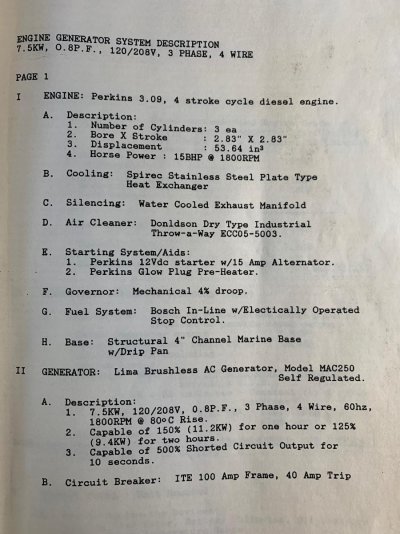

My generator is an old Perkins and it works fine. I rarely use it and mostly just run it for maintenance. I will post some photos of the pulley setup on it and the manual I have. Would it be possible to add a hydraulic pump by replacing a pulley? If yes, how? I can buy the parts and do the work, but I am not a mechanic.

All advice is appreciated.

He is thinking about a generator hydraulic backup solution.

Since I also have hydraulic steering, windlass, autopilot, I would not mind a backup solution for emergencies. I have replaced most of the hydraulic system I have a couple years ago. My hydraulic pump is on the main engine and handles the bow thruster and the windlass. The steering hydraulics is a separate setup with the autopilot. Even if I do not care about steering, I do need the anchor to be pulled up in all cases.

My generator is an old Perkins and it works fine. I rarely use it and mostly just run it for maintenance. I will post some photos of the pulley setup on it and the manual I have. Would it be possible to add a hydraulic pump by replacing a pulley? If yes, how? I can buy the parts and do the work, but I am not a mechanic.

All advice is appreciated.