STB

Guru

@gkesden #24

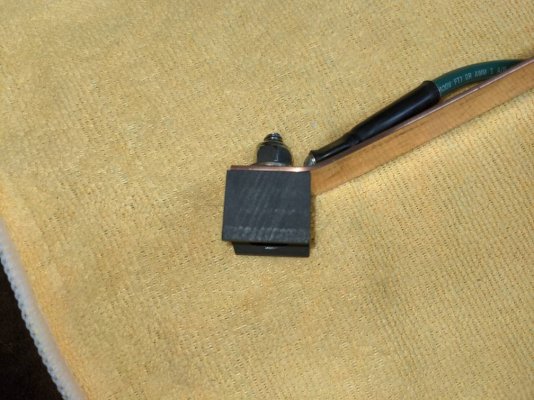

Braid is not allowed because it deteriorates so quickly in the harsh environment that it is used in. Using braid as the contact element between the bonding system and the propulsion shaft certainly violates the intent of ABYC E-2.

As I earlier wrote...

-------

Having said all of that, I'm not sure that I like the idea of a weighted braid over the shaft. And, I'm not sure that a professional electrician would consider it to be good tradesmanship. And, I'm not sure that something somewhere doesn't prohibit it.

------------

ABYC E-2 does not provide guidance about those things for which it does not provide guidance. This is one of them. I think.

If I'm wrong, which is always a possibility, please dont just assert it, please quote the applicable language from the section. Otherwise, as shown in my earlier post, what seemed to be the earlier references, are not applicable.

The reason I push at this is because it isn't the case that whatever the ABYC guidance doesn't explicitly prohibit is a good idea or even a safe idea. This is one such example, I think.

We can't fall into the trap of not thinking things through and not applying significant judgement and tradesmenship, if we want a safe, maintainable system. And, along with that, we can't expect that work we do will be done right if the complexity of the work and circumstances are beyond our experience and judgement. I think.

Simply dismissing ideas that one doesn't like, even if that is based on a lot of experience, as violating the unwritten "intent" of ABYC guidance isn't helpful to the goal of thoughtful trade like installations. I think.

It is okay, for example, to suggest that, based upon one's X years of experience, an installation is likely to be problematic, for example, by quickly deteriorating. I don't think a code cite is required.

In my case, I didn't directly offer the opinion at the time, but I didn't like the braid idea because a bunch of thin exposed wires seemed like a bunch of thin exposed wires anywhere else I have ever seen them in a marine electrical system: very likely to corrode and build up resistance. There is a reason I use conductive or dielectric paste and/or shink connectors with internal adhesive.

It also seems unlikely that the weights would or could be calibrated to the force needed to make good contact, without also pulling at the braid, especially as the boat moved. And, I didn't understand what the internal structure of the braid was to know if it would likely tolerate the mechanical spinning, pulling, and rocking. But, unless engineered for this purpose, that seemed unlikely.

But, for right or for wrong, I only hinted that I didn't like the idea, because it was already done in the person's own boat and the person was monitoring it to see how it did.

Last edited: