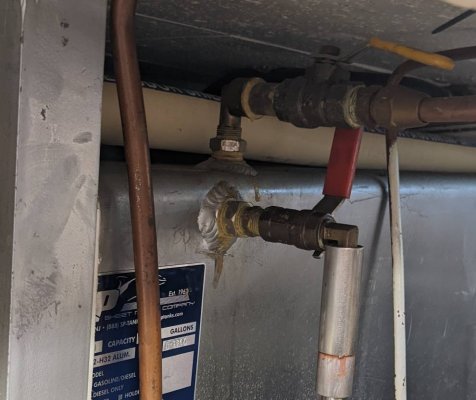

Interesting. So if installed "correctly", the sight tube level would drop with the tank level, and you would only need to push the button to refill the tube when you fill the tank? That would be pretty slick, but I would wonder about the opening pressure of the check valve, and resulting difference in indicated vs tank fuel levels. Might be just fine, or close enough, but I'd want to know.

the level probably won't drop automatically due to spring pressure holding the valve shut. impossible to know what the spring pressure is without having the spec of the valve.

the only time an accurate reading can be taken is when the valve is actuated.

of course, this is all speculation from looking at the valve picture and prior experience with similar plumbing pieces.

i get why they installed those in the first place, as they are automatically closing valves. personally, i'd prefer a ball valve. as was mentioned, those can be serviced, but the tank needs to be empty to do it.

![IMG_3209[1].jpg](/data/attachments/125/125867-e276f0f05b2280c706618511a1c96ebb.jpg)

![IMG_3210[1].jpg](/data/attachments/125/125868-93d71351222a960988f950aa3caf2aab.jpg)

![IMG_3371[1].jpg](/data/attachments/126/126767-d28364db84701529a123511b5284df70.jpg)

![IMG_3375[1].jpg](/data/attachments/126/126768-1908ef1dddeccd8512d7b87a12067666.jpg)