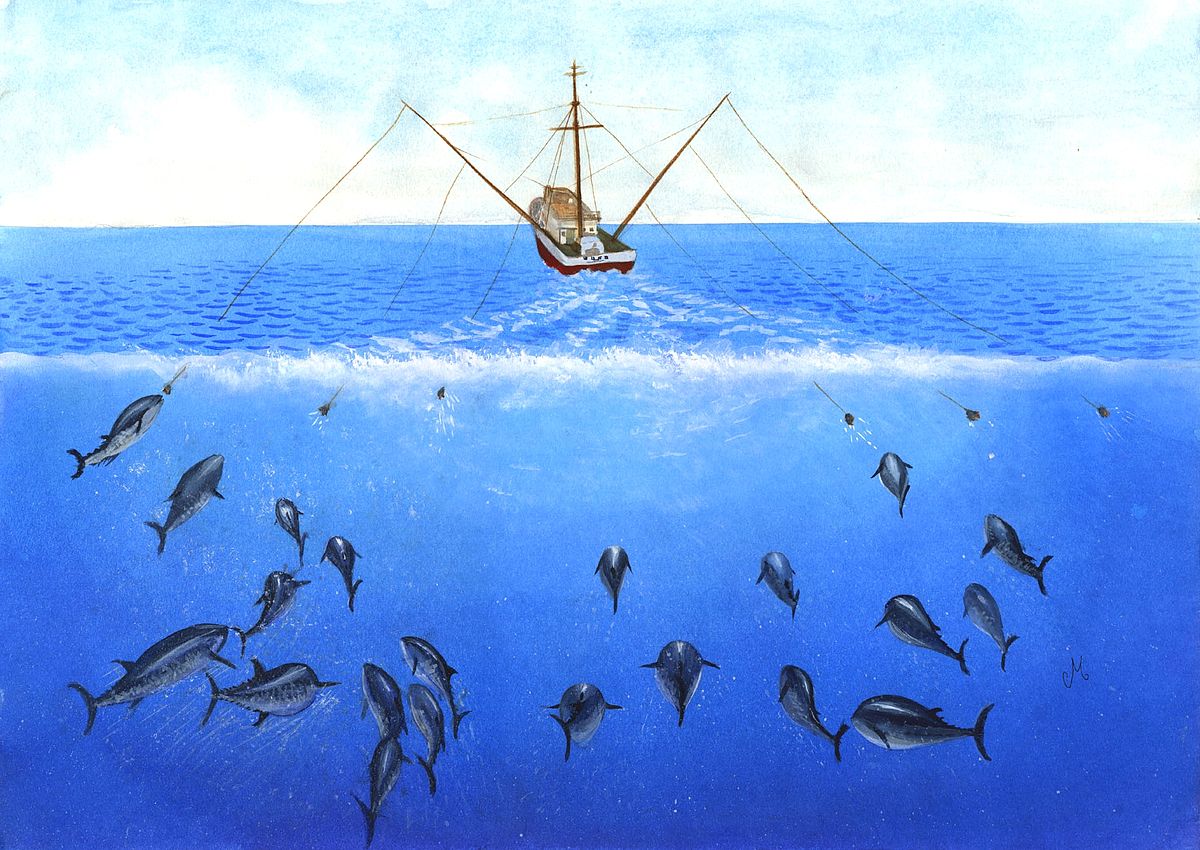

On fishing boats the poles are at about 45° so when rolling the poles don't go in the water. I only put poles in the water once. I don't recommend it. The polls are rigged to transfer the load via the mast to the other side. The pole is fixed so it can't lift. Either with an attachment point low on the hull or with bracing to stout cabin structure. Usually, in addition to the line from the pole tip to the bow, there is another line from the flopper line. midway between the pole and the water and run to the bow. This takes the forward strain off the pole.

Also you may need a hole on the flopper further forward. For running at speed the flopper needs to be near horizontal but with the nose up. For trolling the nose goes down for braking to slow the boat.

.

Totally different requirements on fishing boats

Different loads - we aren't fishing or dragging nets

Different weather - we try to do our miles in calm weather, but occasionally there is unpleasant slop to deal with that hasn't settled down yet and that is what we are doing it for, the 12 hours of beam on slop gets a bit tiring, especial with a wheelhouse at our height.

Not really that noticeable when downstairs on the lounge, but that ain't keeping a proper lookout.

The rig needs to be stout. I doubt a cabin roof, etc., would be strong enough.

So some say but again, I think that is "perfect storm" loadings

As can be seen in the video there is not much load at all when running, not if I can pull belly into the dyneema by hand

Yes there will be more if in rougher conditions but how much?

Other factors to take into account are......

The fish are a smaller size, so less load - slowing the roll, not trying to stop it

The poles are shorter = less leverage - given the same rolling conditions a 6m pole will pull a paravane up through the water approximately twice as far in the same time period as a 3 m pole

You're stopping many tons from rolling. A weak attachment point will be under constant repair

I got told the same with the flopper stoppers he have on.

They stop many tonnes from rolling, or at least slow it down considerably, but reality is, the load is bugger all.

I know the load of paravanes is more, but I don't believe it's as much as some make out.

As an example, I have video of a 55 fter running paravanes in some sloppy conditions and the springs at the end of his poles are working but never fully compressed - but the spring compression rating is 350kg/770 lb.

To me that says the load is surely around that spring rating.

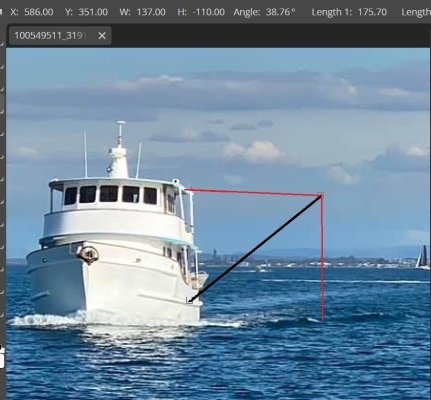

I also mentioned maybe going for longer poles - in the pic below that's a full 6 metre length.

If we go that way they will be mounted at 45 degrees

The load path to the roof will then be near horizontal

The roof then is essentially an I beam with a 15ft web with a 3 ft chain plate attached by 3/8 bolts epoxy set into a deck beam for the attachment points