You should realize that you are taking on a major system regarding maintenance, monitoring, and troubleshooting. The systems are miraculous, but have sensors, control units, and smart actuators that will require your troubleshooting ability at times – guaranteed.

Another factor to put in your choice is where you will be traveling; consider if the manufacturer can get a technician to you without too many airline legs.

The DC electric fins made the most sense to me when I was looking to purchase, especially since I have experience with DC electrics and almost none with hydraulics.

If you are mostly trying to tame the boat in a rolly anchorage, you should really consider flopper stoppers, especially since you have a nice boom on your vessel already.

Good luck and keep us posted.

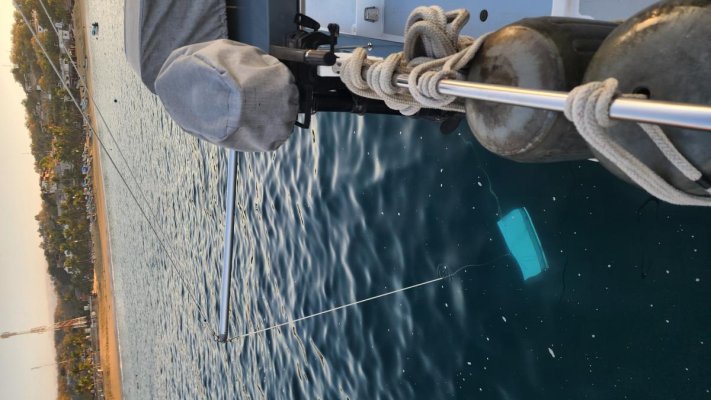

I have thought about flopper stoppers, but since I don't have a mast onboard that option went out the window. Am very curious to hear from people who have them to find out how well they can keep the boat calm in the anchorage. However then you will need towed fins to create some stability while underway.

I cannot comment on maintenance or problems of hydraulic stabilizers, however I can envision them. Same is with pneumatic systems, but since there is so much equipment necessary to work flawless in order for the stabilizers to work perfect.........and having worked with pneumatic systems in the past, I do know there is a lot that can go wrong.

Most fin stabilizers have some sort of shaft sticking out, through the hull, to which the fin is connected. That does mean that if you hit something that shaft can be damaged and now your fins may not work anymore.

Gyros most likely won't have a lot of problems. It is a closed system and if that is built well it will keep working. If you ever have a problem it is most likely to be an electrical problem. That could be a cooling problem or as I wrote before, it is not having enough juice available to power the gyro.

But a big draw back, at least to me, was the fact it needs a total rebuild every 3000 - 5000 hours. We spend about 9 months per year on the boat, which is around 6500 hours. Most of those hours we are on anchor, which means we will get to those 3000 or even 5000 hours every single season, perhaps even twice per season.

The running cost of a gyro are already staggering, but now I have to add 1 or 2 complete rebuilds per year to that as well ? That is too much for me..

As for the electrical fins I did like the fact that maintenance is minimal. The motor unit is self contained and is completely sealed. It is powered with 220 V AC (at least mine are) and there is not a lot that can go wrong with the motor. I spoke with several charter boats that have electrical fins already for 5 years and they had not had a single motor failure.

If you hit something in the water, e.g. a log or container, the fin will be ripped off, it is designed to break off. Then you will have to bolt a new fin to the motor and off you go.

What I will need to do is change the outer seals every 5000 hours, but after I spoke with the producer of the stabilizers they agreed that I can postpone it until the end of the season when the boat is coming out of the water anyway. And changing the seal will take half a day apparently, I can live with that since it keeps the costs down. As stated before the operating costs are minimal, which I also like.

Every stabilizer will have a control box and most important part with those boxes is to keep them cool. That means cleaning the air filters and making sure the small ventilators (same ventilator as any computer has) function well.

And then there is the issue of who is going to do the maintenance. Most producers do have an extensive service network, where you can make a difference between companies that are allowed to do installations (plus repairs after damage) and companies that can only do standard maintenance.

It is definitely something to take into consideration when you decide on a stabilizing system, especially when you know you will have to do a lot of standard maintenance on the system. With that in mind also check how long the warranty period is and what is in- and excluded.

In my case there are enough service stations around in the Med where I can go to if something goes wrong.