That’s a high price for a single bushing.

https://www.freshwatersystems.com/p...Je0HaFUU_L7j0Vurok9ZuC_IwcsJAZhhoC99UQAvD_BwE

https://www.freshwatersystems.com/p...Je0HaFUU_L7j0Vurok9ZuC_IwcsJAZhhoC99UQAvD_BwE

That’s a high price for a single bushing.

https://www.freshwatersystems.com/p...Je0HaFUU_L7j0Vurok9ZuC_IwcsJAZhhoC99UQAvD_BwE

this price is better, but after shipping charge, home depot still wins

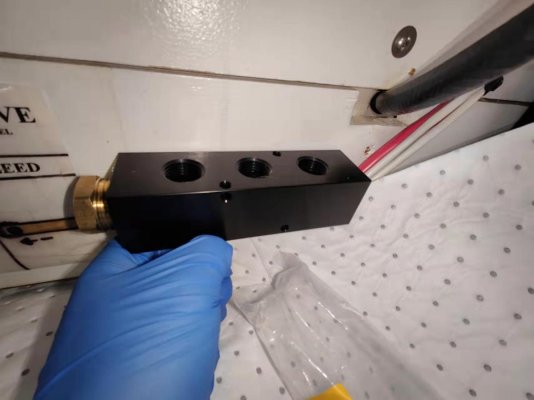

Oops, I forgot to link the manifold. https://www.automationdirect.com/adc/shopping/catalog/pneumatic_components/manifolds/mra-5fd

Only you can decide if it’s the right place. I like to loosely install all the components and then choose my location so that I can easily see it, and the valves are easily accessible, then visualize the hose runs.

Take out a nearby screw so you can figure out the thickness of the mounting panel. Your screw should ideally penetrate as far as possible without punching through the backside.

If you are undecided about the perfect location, you could use double-sided tape.

I keep an assortment of pan head wood/self-threading screws that would do, too.

It would probably be better to just bite the bullet and screw it down solidly.the manifold plus those bushing fittings and 3 ball values is quite heavy. Is the tape only used to assist finding the optimal location?

does backside refer to the plywood panel or the perforated board behind the wood panel?

I would mount to the plywood. If there are acoustic tiles over the plywood, you need to have screws long enough to go through the tiles and into the plywood. If the plywood is over the tiles, just go through the plywood. If it goes into the tiles, no biggie. But remember, There’s no screw holding strength in the tiles.

Due to the possibility of diesel dissolving zinc, purists may avoid any alloys

containing zinc, as brass does.

I have found that any metal will be compatible except galvanized iron or steel.

I have used Home Depot piping when that was all I had but your manifold is a

one-time build that may benefit from using a better quality of components. For

example, I like to use hex nipples on something like this even though they cost

a bit more.

McMaster-Carr sources their pipe components domestically, AFAIK, and should

have better quality control than what I've found at HD.

Thanks.

the acoustic tiles are hard to the feel. are they usually made of vinyl?

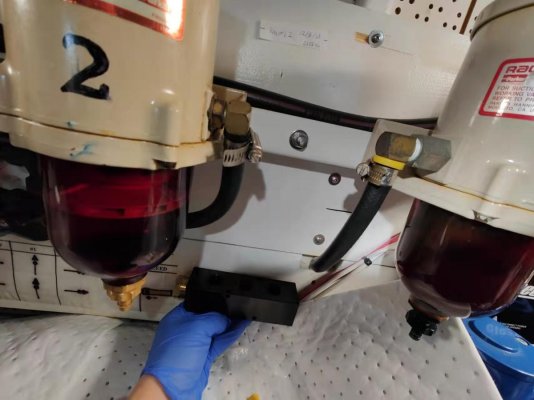

I just learned my racor is an earlier model that has 9/16" or ORB #6 fuel ports.

there is not a ORB 6 to 3/4" barb fitting, so I need a ORB 6 male to ORB 8 female fitting

the fitting 6410-06-08 that is universally available is made of steel with zinc plating. Is this galvanized steel? The same fitting is also available in stainless steel but costs $70+

The tiles are usually made from some kind of pressed fiber. Not sure of the actual base material. I do know a screw will easily pull out if you load it.

Here’s one in anodized aluminum

https://www.racetronix.biz/p/adapter-8-orb-fml-6-orb-male-blk/adf-rf0806