Serene

Senior Member

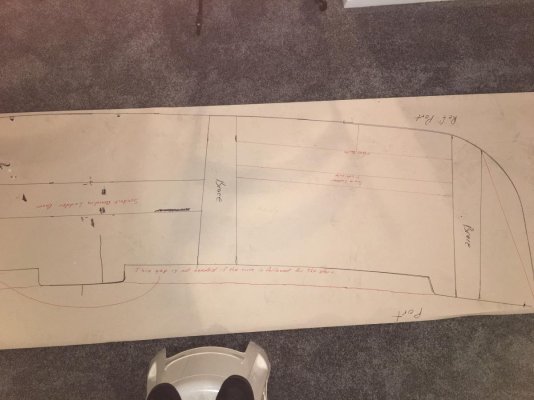

Boat is now out of the water for the next phase of my refit and have removed the swim platform. Idea was to refurbish it and put it back in place.

The brackets look to be made of bronze and are in serviceable condition, but upon closer inspection the timber swim platform has numerous cracks and some soft areas.

Looking for ideas, as to whether I refurbish or replace?

Do I keep the bronze brackets and have a new wood platform made? Problem will most likely be in finding new teak/beech, which I would expect is the required timber due to the wood being in a semi-submersed location. i.e. when underway.

Other option is to have an aluminium item made, with aluminium welded brackets to replace the bronze items, which also gives me the option of making it a larger area. Concern with this idea is possibility of electrolysis given it will be partially submerged and close to the bronze rudder and propellor.

Other option would be to have a stainless steel frame made and use some sort of composite planking to make the deck. But not sure what material to use.

Anyway have attached some pics for context and looking for suggestions.

Will talk to the boatbuilder tomorrow to get his ideas, and also visit the on-site metal fabrication shop to see what they say.

The brackets look to be made of bronze and are in serviceable condition, but upon closer inspection the timber swim platform has numerous cracks and some soft areas.

Looking for ideas, as to whether I refurbish or replace?

Do I keep the bronze brackets and have a new wood platform made? Problem will most likely be in finding new teak/beech, which I would expect is the required timber due to the wood being in a semi-submersed location. i.e. when underway.

Other option is to have an aluminium item made, with aluminium welded brackets to replace the bronze items, which also gives me the option of making it a larger area. Concern with this idea is possibility of electrolysis given it will be partially submerged and close to the bronze rudder and propellor.

Other option would be to have a stainless steel frame made and use some sort of composite planking to make the deck. But not sure what material to use.

Anyway have attached some pics for context and looking for suggestions.

Will talk to the boatbuilder tomorrow to get his ideas, and also visit the on-site metal fabrication shop to see what they say.