I have 6CTA8.3 450HP engines. I have Sea Board Marine (Tony) here at my harbor. He is the Cummins guru locally and on the web.

https://www.sbmar.com

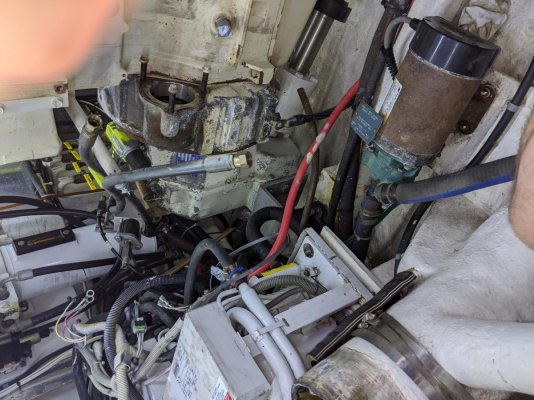

I did everything "Tonys way" That means every bolt has HD marine greese on it. Every hose fitting has rector seal yellow on it. Every water hose has rector seal black sealing it. Turbos were sealed wit red RTV, mounting studs treated with high temp anti-seize.

I used Rust-oleum 2X Ultra Cover® spray paint (gloss white).

I stripped the motors down to the block,head and left the high preassure side of the fuel injection in place. Sanded and cleaned everything. Used DrX rust remover on all rust. I also use DRX for brass on the thru-hulls and sea strainers.

https://drx1.com/

Primed with Rust-Oleum gray primer then painted.

Every part I removed from the engine I stripped to bare steel, treated any rust with DrX and painted with 2X Ultra Cover® spray paint (gloss white).

I replaced every Hose, Belt and hose clamp. Bought new after cooler housings, new Transmission coolers and water pumps. Had the heat ex-changers cleaned and pressure tested.

I added fresh water flush systems to both engines, AC pump and generator.

By leaving the high pressure side of the fuel injection untouched, i just did a normal fuel bleed on the low pressure side and the engine fired right up!

I budgeted $20,000.00 total for both engines and will come in closer to $21,000. That also included making a new exhaust for Starboard engine and custom exhaust blanket.

I'm very pleased with the end results. Both engines look and run like new.

I now have a base line for all future maintenance.

Doug D

2000 McKinna 48PH

New Adventure