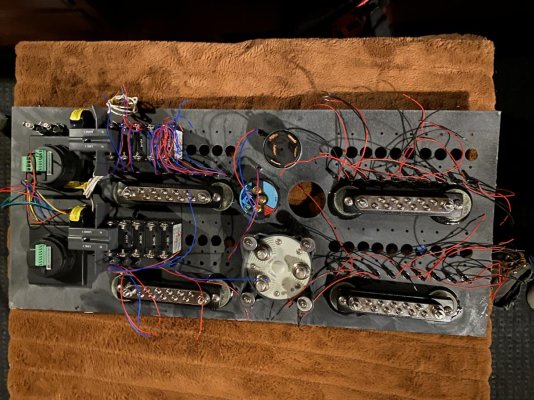

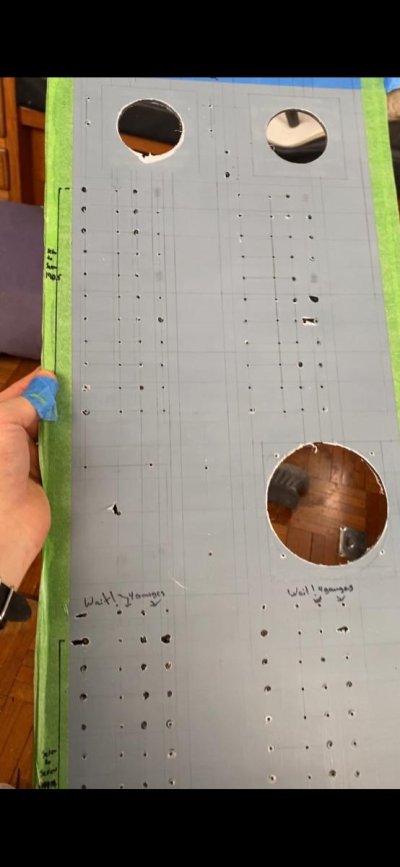

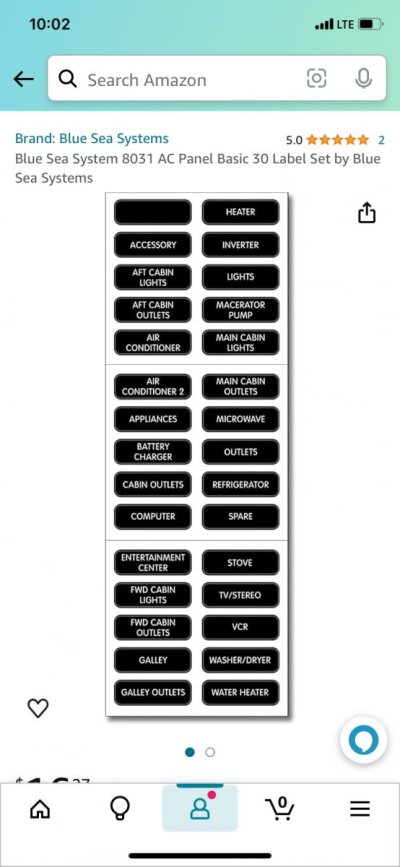

Figured I’d post my breaker panel built. This was a tough project and I didn’t get any ideas on other peoples builds because it’s not a very common thing to do and now I know why… I spent countless hours researching, finding the right components, making sure everything fits blah blah blah. Most of the components are Blue Sea Systems and some other less important things I bought on Amazon. I can answer questions as they come. This setup should give me exactly what I need, but I still have more work to do.

I wanted to think those who wait in on a few electrical issues I had in the past as well. Here are those links.

https://www.trawlerforum.com/forums/s32/diy-weld-mount-panel-fastening-71104.html#post1218732

https://www.trawlerforum.com/forums/s4/isolation-transformer-neutral-ground-connections-70843.html

I wanted to think those who wait in on a few electrical issues I had in the past as well. Here are those links.

https://www.trawlerforum.com/forums/s32/diy-weld-mount-panel-fastening-71104.html#post1218732

https://www.trawlerforum.com/forums/s4/isolation-transformer-neutral-ground-connections-70843.html