GoneDiving: I'm looking to isolate the engine room noise and vibration from the helm and salon (above) and the bedroom cabins (separated by a steel bulkhead)

Do people normally insulate all walls and ceiling? Or is it enough to insulated only the joining wall and ceiling/sole?

Steel and aluminum present different treatments than fiberglass or wood. Later on that. Primary insulation should be on all panels common with accommodation spaces. This means forward bulkheads, ER overheads and perhaps aft bulkheads depending on what's on the other side. These surfaces should be treated with an absorption/barrier/de-coupler insulation similar to what FF mentioned.

GoneDiving: Is there benefit to having insulation on fuel tanks mounted along the sides within the engine room?

Other surfaces like hull sides and tanks MAY be insulated, but only an absorber is necessary as we typically don't care if noise gets into a tank or out the sides of a hull. For absorption to have an effect there must be a high % of absorption in the overall ER, and the performance will be measurable and maybe noticeable but not significant. A better place to put cost and effort would be sealing the many "leaks" often found around doors and penetrations. Gasket and void fillers around piping and conduits can reduce noise transmission by up to 5 Db with very low cost.

One of the biggest noise contributors to accommodation spaces is combustion/ventilation air trunks. If these trunks intrude above the ER overhead they can be a massive noise "leak" if not treated.

GoneDiving: Does being above/below the waterline have an affect?

Insulation below the waterline would not typically be recommended. ER insulation would typically only go down an ER bulkhead to the deck level of the accommodation deck. If you have open bilges that noise can travel through there are treatments to reduce noise transmission without stopping water flow.

GoneDiving: Is their benefit to insulating both sides of the ER/bedroom bulkhead wall?

YES. For example it would always be recommended to use an acoustic carpet underlayment (if the deck was carpeted) in a salon above an ER, even if the ER overhead was insulated. More "stuff" between you and the noise.

Some common rules of noise control are:

Treating noise as close to the source as possible will provide the best results

The more "stuff" between you and the noise will reduce noise transmission

Mass stops noise, not soft stuff like foam or fiberglass.

Soft stuff is an absorber, not a noise barrier.

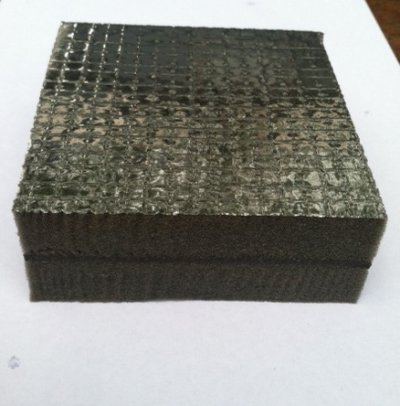

Barriers with absorbers and de-coupler layers on either side work best

For a metal boat there are some different considerations. A non combustible insulation like fiberglass/lead should be considered instead of a vinyl/foam composite. Your vessel is made of a non combustible material, perhaps your ER insulation should be too. There is an increase in cost for non combustible insulation so that may play part in the product decision.

A last thought on vibration. Engine and exhaust vibration will transmit very nicely in a metal boat. When the time is right new or higher performance engine mounts will make a difference. How your exhaust is attached to the structure of the vessel is worth taking a look at as well. Any connection should be resilient, not rigid. Exhaust attached to the overhead should be avoided if at all possible. Also if you have stanchions supporting the deck above the ER, these are great little vibration transmission paths, and depending their configuration there are treatments.

Theese are very general comments, your results may vary

$0.02

Vinyl/Foam and Fiberglass/Lead

Steel and aluminum present different treatments than fiberglass or wood. Later on that. Primary insulation should be on all panels common with accommodation spaces. This means forward bulkheads, ER overheads and perhaps aft bulkheads depending on what's on the other side. These surfaces should be treated with an absorption/barrier/de-coupler insulation similar to what FF mentioned.

Steel and aluminum present different treatments than fiberglass or wood. Later on that. Primary insulation should be on all panels common with accommodation spaces. This means forward bulkheads, ER overheads and perhaps aft bulkheads depending on what's on the other side. These surfaces should be treated with an absorption/barrier/de-coupler insulation similar to what FF mentioned.