Dear Community,

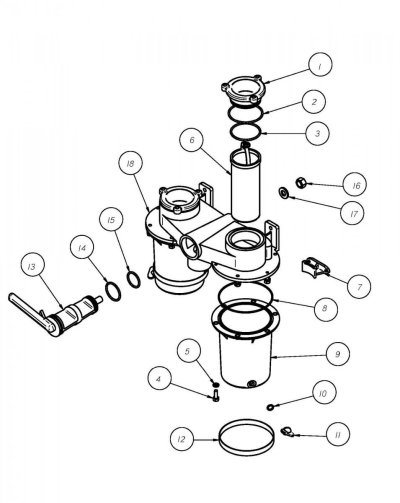

My boat is equipped with a Groco Duplex Strainer.

Unfortunately not too much information about that solid piece around. Except: it should be possible to clean one side while the other side is in operation.

Well, somehow that does not work on my unit. Whichever side I select to be in operation, cooling liquid will leak heavily and drain the engine oil f coolant when I try to open for cleaning. I tried the ‘dead’ side as well as the ‘operating’ side,

What I discovered is that the valve rotates only 90 degrees while the handle swings over by 180 degrees. Might there have been a mistake when installing the unit / handle?

I’ll attach pictures for clarification.

Any advice on proper installation and operation of the Groco Dublex Strainer highly appreciated.

My boat is equipped with a Groco Duplex Strainer.

Unfortunately not too much information about that solid piece around. Except: it should be possible to clean one side while the other side is in operation.

Well, somehow that does not work on my unit. Whichever side I select to be in operation, cooling liquid will leak heavily and drain the engine oil f coolant when I try to open for cleaning. I tried the ‘dead’ side as well as the ‘operating’ side,

What I discovered is that the valve rotates only 90 degrees while the handle swings over by 180 degrees. Might there have been a mistake when installing the unit / handle?

I’ll attach pictures for clarification.

Any advice on proper installation and operation of the Groco Dublex Strainer highly appreciated.