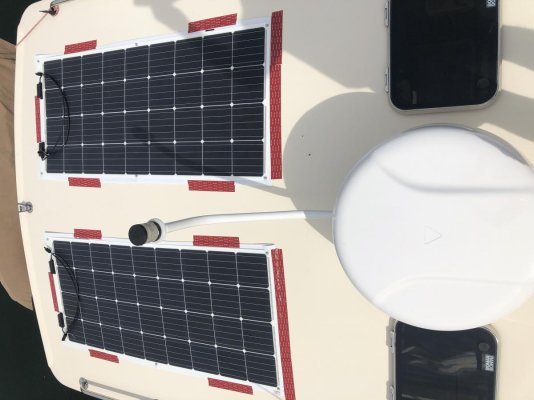

Hi. We have a NT 32 and are needing solar as our boat will be on a mooring buoy all summer. We are mounting them ourselves and have an electrician who will do the set up. My question is whether to create a railing system to hold the panels, which many NT owners have done across the top of their pilot house, or to adhere 6 hdpe blocks with hinges screwed into the blocks to hold each panel (2 300 watt panels, ~35" x 60").

My electrician mentioned that 3m 5200 adhesive is a bear to get off and can damage the roof if we ever changed our minds. He didn't have concerns about it holding. And an adhesive approach is more appealing due to cost. It's a bit more minimalist and cleaner. Could a 4200 work and be removable yet secure? I've seen an example so others have done this.

Railings are more $ but if we ever needed to change our solar panels it could accommodate different sizes. It is also what I've seen on most Nordic Tugs and I haven't heard anyone complain about this approach.

Thoughts?

My electrician mentioned that 3m 5200 adhesive is a bear to get off and can damage the roof if we ever changed our minds. He didn't have concerns about it holding. And an adhesive approach is more appealing due to cost. It's a bit more minimalist and cleaner. Could a 4200 work and be removable yet secure? I've seen an example so others have done this.

Railings are more $ but if we ever needed to change our solar panels it could accommodate different sizes. It is also what I've seen on most Nordic Tugs and I haven't heard anyone complain about this approach.

Thoughts?