You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dear Diary - Weebles will splash soon.

- Thread starter mvweebles

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Monday, January 23 2023. Being Sunday, not much to report yesterday. The front room of my apartment is chock-a-block full of boat gear. I had had a storage unit until October when the storage complex sold and closed. It was a blessing in disguise at it forced me to pare down, but my apartment is now part warehouse.

I originally found my apartment on AirBNB (LISTING IS HERE) but now rent direct from the owner. It's a short walk from the main downtown area so very convenient. The apartment itself is one of three units in a converted house that used to be a combo doctors office (downstairs) and home (upstairs). I've stayed in all three units - a 1-bdrm (current); a studio; and the upstairs 2-bdrm. Cost is $800/mo with weekly housekeepng, and there is secure parking.

Now, $800/mo is pretty affordable so I don't mean to sound ungrateful, but this is an AirBNB apartment in Mexico. I've traveled a bit in Mexico and it seems there are a lot of people carving-up their houses into AirBNB rentals. The pictures are accurate but do not give a full sense of the unit. Bathroom fixtures are old. Thick globs of silicone caulk on the shower glass. Pots/pans are old and worn. You get the idea. A step-up from college. But it's clean, safe, very convenient, and relatively comfortable. My biggest complaint - a minor one - is the furniture is all very low and I need a trapeze bar to hoist myself out (the owner is slighly built - perhaps 5'3" tall which perhaps explains the furniture).

So Sunday is laundry day and prepare-to-move-onto-Weebles day (which will last for several days). I also organized the projects I want Orlando (electrician) to do - Weebles will be ready to splash no later than Wednesday, but I have a few things I want Orlando to install. Some, like a horn, should have been installed while Weebles was under construction (my fault - he asked a couple months ago). Others, the Victron Cerbo, are a recent add-on. Another - the hailer speaker - I totally forgot about.

I'm eager to see the McQueen (wood motoryacht hauled on Saturday) this morning. Maybe the crunched chine log healed itself. Doubtful, but maybe.

Peter

I originally found my apartment on AirBNB (LISTING IS HERE) but now rent direct from the owner. It's a short walk from the main downtown area so very convenient. The apartment itself is one of three units in a converted house that used to be a combo doctors office (downstairs) and home (upstairs). I've stayed in all three units - a 1-bdrm (current); a studio; and the upstairs 2-bdrm. Cost is $800/mo with weekly housekeepng, and there is secure parking.

Now, $800/mo is pretty affordable so I don't mean to sound ungrateful, but this is an AirBNB apartment in Mexico. I've traveled a bit in Mexico and it seems there are a lot of people carving-up their houses into AirBNB rentals. The pictures are accurate but do not give a full sense of the unit. Bathroom fixtures are old. Thick globs of silicone caulk on the shower glass. Pots/pans are old and worn. You get the idea. A step-up from college. But it's clean, safe, very convenient, and relatively comfortable. My biggest complaint - a minor one - is the furniture is all very low and I need a trapeze bar to hoist myself out (the owner is slighly built - perhaps 5'3" tall which perhaps explains the furniture).

So Sunday is laundry day and prepare-to-move-onto-Weebles day (which will last for several days). I also organized the projects I want Orlando (electrician) to do - Weebles will be ready to splash no later than Wednesday, but I have a few things I want Orlando to install. Some, like a horn, should have been installed while Weebles was under construction (my fault - he asked a couple months ago). Others, the Victron Cerbo, are a recent add-on. Another - the hailer speaker - I totally forgot about.

I'm eager to see the McQueen (wood motoryacht hauled on Saturday) this morning. Maybe the crunched chine log healed itself. Doubtful, but maybe.

Peter

Attachments

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Yep. If Guillermo puts it on stands there's a good chance he'll end up owning it.

It is definitely a concern for him. He took some steps to protect himself - the work is mostly prepaid. The boat is actually in decent shape, at least from the exterior. As mentioned, bottom was clean, generator and thruster were clearly running when she came in. I couldn't tell for sure, but I think her main engines were also running - the tow boats may have been for maneuvering since the entrance into the boatyard is very tight.

Many lessons' learned about wood boats. At least along this coast of California, they are viewed with a great deal of skepticism, and few yards will deal with them. I suspect marinas are similar. May be different in PNW, but in SoCal at least, owning a wood boat is challenging beyond simply maintaining it.

I'll be at the yard later this morning.

Peter

Jeff F

Guru

- Joined

- Nov 5, 2015

- Messages

- 2,437

- Location

- Canada

- Vessel Name

- Escapade

- Vessel Make

- 50` US Navy Utility trawler conversion

Not just SW. I had some work done on Escapade in Nova Scotia at Lunenburg Foundry and Engineering Shipyard.

They were on their last gasps when I was there, and are now closed. They had two marine railways that could handle ships up to maybe 200 ft. Three Bluenose sailboats over close to 100 years were built there. Those guys could block and lift anything.

There are perhaps two such facilities left in the province.

They were on their last gasps when I was there, and are now closed. They had two marine railways that could handle ships up to maybe 200 ft. Three Bluenose sailboats over close to 100 years were built there. Those guys could block and lift anything.

There are perhaps two such facilities left in the province.

RickyD

Guru

- Joined

- May 4, 2018

- Messages

- 732

- Location

- United States

- Vessel Name

- Aquarius

- Vessel Make

- Californian 55 CPMY

Lifting wood hulls with a travel lift can be tough. It's sensitive to where you lift, how long it's in the slings, etc. Ideally you want to get it blocked fairly quickly and not lift with full tanks. Even then, as you saw, if the hull has issues, they're likely to show up. But if an appropriate number of slings are used and the placement is good, issues like that are typically stuff that needs to be fixed regardless.

A sailboat neighbor of mine took his to be hauled. It was an old woody. The yard refused to lift.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

1981 84' McQueen MY - More pictures

There seemed to some interest in the McQueen motoryacht that was hauled 2-days ago, I was back at the yard this afternoon and snapped a few pictures.

Recall.......when the boat was hauled on Saturday, there was some compression damage from the travel lift (this is a repeat photo). I talked to Guillermo and he was aware this was a possible issue, but the owner had little choice - no one in San Diego would haul a large wooden boat (something to remember).

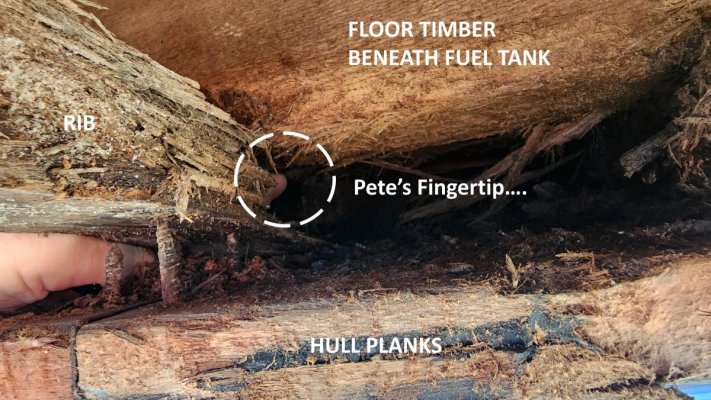

The compression areas largely recovered, though there is one sprung plank. This is under the fuel tank and inaccessible. A few boards will be removed to inspect the ribs. Second picture is the chine-clamp board that has some minor rot in a few places, and definitely need to be recaulked

Overall, the planking looks good.

Turns out the hull-lines are cosmetic, just as they are on Weebles. You can see a 'step-crack' in the paint showing the planking. This is a cosmetic crack and not indicative of any structural damage. The boat is over 40-years old - it needs to be taken-down to bare wood and repainted. No different than a house would need.

Mahogany wood was used in construction with stainless steel fasteners, which was surprising to me - I expected bronze fasteners. Robertson "Square Drive" heads were used which has to be a relief compared to slotted head fasteners. I wonder if the blackening of the wood around the fasteners is due to use of stainless?

There seemed to some interest in the McQueen motoryacht that was hauled 2-days ago, I was back at the yard this afternoon and snapped a few pictures.

Recall.......when the boat was hauled on Saturday, there was some compression damage from the travel lift (this is a repeat photo). I talked to Guillermo and he was aware this was a possible issue, but the owner had little choice - no one in San Diego would haul a large wooden boat (something to remember).

The compression areas largely recovered, though there is one sprung plank. This is under the fuel tank and inaccessible. A few boards will be removed to inspect the ribs. Second picture is the chine-clamp board that has some minor rot in a few places, and definitely need to be recaulked

Overall, the planking looks good.

Turns out the hull-lines are cosmetic, just as they are on Weebles. You can see a 'step-crack' in the paint showing the planking. This is a cosmetic crack and not indicative of any structural damage. The boat is over 40-years old - it needs to be taken-down to bare wood and repainted. No different than a house would need.

Mahogany wood was used in construction with stainless steel fasteners, which was surprising to me - I expected bronze fasteners. Robertson "Square Drive" heads were used which has to be a relief compared to slotted head fasteners. I wonder if the blackening of the wood around the fasteners is due to use of stainless?

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Tuesday, January 24th 2023. Decent progress yesterday, and Weebles is on-track to being unwrapped today (I think). Tomorrow will be final clean-up in prep for launch, though I will delay launch for a couple days to give Orlando (electrician) unobstructed time to install some last items (Noland RS11 to convert engine instrument readout to N2k; Victron Cerbo; additional circuit breakers for solar panels; an airhorn; exterior hailer speaker for VHF; and an additional wash-down outlet in the cockpit).

PICTURES:

1. Scupper covers installed. Recall, these are made from GPO3 sheeting and 316 SS hinges from McMaster. Bungee material will gently bias them closed.

2. Non-Skid being taped. Final step in painting is to do the non-skid. Two workers spent about 6-hours taping-off the non-skid patches. I was at the boat at 3pm yesterday - the actual paint was supposed to be applied yesterday afternoon which seeed late to me so I won't be surprised if it gets painted this morning. Guess I'll find out in a few hours.

PICTURES:

1. Scupper covers installed. Recall, these are made from GPO3 sheeting and 316 SS hinges from McMaster. Bungee material will gently bias them closed.

2. Non-Skid being taped. Final step in painting is to do the non-skid. Two workers spent about 6-hours taping-off the non-skid patches. I was at the boat at 3pm yesterday - the actual paint was supposed to be applied yesterday afternoon which seeed late to me so I won't be surprised if it gets painted this morning. Guess I'll find out in a few hours.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

McQueen Update - Tuesday

Several of the bottom planks have been removed. Turns out the fuel tanks are full - a good 1000 gals aboard, or 7000 lbs. Note to self - make sure the tanks are empty on a big wooden boat. These will be emptied into a storage tank prior to launch when the time comes.

I don't know much about wood boat construction, though I am very familiar with carpentry and house construction having done a ton of remodeling. Forgive me if the nomenclature of wood boat construction are not correct.

The ribs appear to be around 12"-14" spaced, appear to be around 2" x 6", though the ends have wedges and are taller where they connect to the chine log. They are, to my eyes, fairly thin in height where the floor timbers that support the tanks are located (the floor timber is the upright 2x10, light colored beam in the picture).

Several of the ribs are cracked - this one is the most easily seen. I would estimate 14 ribs will need to be sistered. While a major job, the cost of this is pure labor - doing this in Mexico at $17/hr is a really good thing for the owner.

If you look really carefully, you can see some crushing of the ribs due to rot. That said, the planks are solid, and most of the wood is solid.

I managed to peek aboard the boat. It's a time capsule - it's really a relic of the 1970's and was quite opulant when launched I am sure. She's in decent condition and while the above repairs are a concern, I would categorize them as normal maintenance of a wood boat after 40+ years afloat. I can understand the appeal to the owner, though the size of an 82-foot boat is daunting.

Peter

Several of the bottom planks have been removed. Turns out the fuel tanks are full - a good 1000 gals aboard, or 7000 lbs. Note to self - make sure the tanks are empty on a big wooden boat. These will be emptied into a storage tank prior to launch when the time comes.

I don't know much about wood boat construction, though I am very familiar with carpentry and house construction having done a ton of remodeling. Forgive me if the nomenclature of wood boat construction are not correct.

The ribs appear to be around 12"-14" spaced, appear to be around 2" x 6", though the ends have wedges and are taller where they connect to the chine log. They are, to my eyes, fairly thin in height where the floor timbers that support the tanks are located (the floor timber is the upright 2x10, light colored beam in the picture).

Several of the ribs are cracked - this one is the most easily seen. I would estimate 14 ribs will need to be sistered. While a major job, the cost of this is pure labor - doing this in Mexico at $17/hr is a really good thing for the owner.

If you look really carefully, you can see some crushing of the ribs due to rot. That said, the planks are solid, and most of the wood is solid.

I managed to peek aboard the boat. It's a time capsule - it's really a relic of the 1970's and was quite opulant when launched I am sure. She's in decent condition and while the above repairs are a concern, I would categorize them as normal maintenance of a wood boat after 40+ years afloat. I can understand the appeal to the owner, though the size of an 82-foot boat is daunting.

Peter

Last edited:

Jeff F

Guru

- Joined

- Nov 5, 2015

- Messages

- 2,437

- Location

- Canada

- Vessel Name

- Escapade

- Vessel Make

- 50` US Navy Utility trawler conversion

These will be emptied into a storage tank prior to launch when the time comes.

Or liquidated to fund disposal. Pardon the pun.

That's probably overly harsh. Just sticking with my earlier gloomy comment.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Wednesday January 25th. Things are progressing. The non-skid was sprayed yesterday midday which means today will be 'reveal day' with Weebles being unwrapped from her cocoon of plastic wrap. The new, thicker breast plate has been fabricated and is ready for final polish and install, probably today. Orlando, the electrician, has the parts needed for final bits and will probably get started tomorrow. Finally, Serafin, the canvas guy, has finished the dinghy cover and awaits access to Weebles. Guillermo tells me my coveted space in the yard has been assigned to another incoming boat that arrives next week, so I guess I am within single-digit days of being afloat. In a way, less about being 'done' than just not having anything left on the list.

I had lunch with Guillermo yesterday (shrimp diabla - excellent!) who related that his 17-year old son Emil is cranky because he must perform community service. Seems that because the government provides free school, they ask the kids to give-back time doing something, frequently picking-up trash or weeding along the roadside, tasks we reserve for low-level offenders in the US. One of the things I have noticed about Mexico is shop-owners tend to keep their premises really clean - not unusual to see someone wash-down the sidewalk every morning. I have to wonder if this is somehow connected with the early learnings. Seems like a good idea - I know many church groups have a give-back mentality, but what if we as a society did more? Where would we be as a community of neighbors?

PICTURES:

1. Hull Gate. Jorge was not happy with his on-board tweaks a few days ago so he removed the hull gate and built-up a few areas with epoxy. Near the long strip of blue tape you can see a thin batton of wood as dam for the fairing compound.

2. Buffing has begun. Jorge has started buffing the hull. My hunch is the boat will be unwrapped today and the final clean-up will proceed through tomorrow. These guys really do a nice job. As an aside, you don't see much facial hair in this part of Mexico, certainly not much ZZ Top style beards such as Jorges.

3. Breast Plate. I keep forgetting my calipers to measure thickness of the prior breast plate (what were those guys on the Hack Team thinking???) vs this muy-gusto plate. It took two guys to bend it into place, one of whom (Alberto) is strong as a team of oxen. Shaking hands with him feels like shaking hands with Johnny Bench ----- with his catcher's mitt on!.

I had lunch with Guillermo yesterday (shrimp diabla - excellent!) who related that his 17-year old son Emil is cranky because he must perform community service. Seems that because the government provides free school, they ask the kids to give-back time doing something, frequently picking-up trash or weeding along the roadside, tasks we reserve for low-level offenders in the US. One of the things I have noticed about Mexico is shop-owners tend to keep their premises really clean - not unusual to see someone wash-down the sidewalk every morning. I have to wonder if this is somehow connected with the early learnings. Seems like a good idea - I know many church groups have a give-back mentality, but what if we as a society did more? Where would we be as a community of neighbors?

PICTURES:

1. Hull Gate. Jorge was not happy with his on-board tweaks a few days ago so he removed the hull gate and built-up a few areas with epoxy. Near the long strip of blue tape you can see a thin batton of wood as dam for the fairing compound.

2. Buffing has begun. Jorge has started buffing the hull. My hunch is the boat will be unwrapped today and the final clean-up will proceed through tomorrow. These guys really do a nice job. As an aside, you don't see much facial hair in this part of Mexico, certainly not much ZZ Top style beards such as Jorges.

3. Breast Plate. I keep forgetting my calipers to measure thickness of the prior breast plate (what were those guys on the Hack Team thinking???) vs this muy-gusto plate. It took two guys to bend it into place, one of whom (Alberto) is strong as a team of oxen. Shaking hands with him feels like shaking hands with Johnny Bench ----- with his catcher's mitt on!.

Choices

Guru

- Joined

- Apr 16, 2018

- Messages

- 899

- Location

- Montgomery, Tx

- Vessel Name

- Choices

- Vessel Make

- 36 Grand Banks Europa

How did they do nonskid? Did they roll paint, spray material, then roll paint? Is it Awlgrip?

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

How did they do nonskid? Did they roll paint, spray material, then roll paint? Is it Awlgrip?

I'm not entire certain how the grit was applied. I know it is sprayed AlexSeal (whisper gray, a light gray), but not sure how the grit is applied in a consistent pattern, which it is. I'll find out this morning and post an update this afternoon, probably with pictures of progress on the wood McQueen motoryacht that has piqued my interest immensely.

Peter

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Here some pics of the nonskid. They actually mix the powdered material in the paint and spray it with the abrasive. It's very fine powder but globs-up a bit once applied to give good purchase. The wonders of modern marine coatings. Hail AlexSeal!!How did they do nonskid? Did they roll paint, spray material, then roll paint? Is it Awlgrip?

Peter

twistedtree

Guru

The boat sure is looking fantastic. You must be REALLY excited...

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Thanks for the good thoughts.

Shots from the boatyard today.

1. McQueen Update

Guillermo tells me Felipe has been working on wood boats for 30-years. He used to work at Baja Naval and did all the wood-boat work there. He did a fair amount of the cabinetry work on Weebles and I liked his work a lot. Very methodical worker.

There are several ribs visible now. This is the worst of them - where the floor timber rests has destroyed the rib. You can see my finger through the rotted section. I count 14 ribs that will need repair or replacing. In all candor, because the planks can be removed, this is time consuming but not the end of the world. I would have thought a boat built by a respectable yard in Canada would have stiffer ribs. Now I'm eager to see how Malahide trawlers are built - I recall ads for them touting the heavy construction. It means something to me now.

2. Other boats in the yard that caught my eye.

Almuminum fishing boat (herring boat????). What caught my eye was the way the zincs are mounted - very serviceable. And well protected to prevent lines from catching.

Same boat but a week ago before it was painted. Note the cage around the prop to help keep lines clear.

72-foot Marquis go-fast boat. La Costa painted the hull and the radar/KVH domes. They also serviced the props and rudders. It has a huge hydraulic swim platform that I'm sure could support the entire Corona Girls Volleyball Team. Second pic is being buffed - will be launched in a day or two.

Shots from the boatyard today.

1. McQueen Update

Guillermo tells me Felipe has been working on wood boats for 30-years. He used to work at Baja Naval and did all the wood-boat work there. He did a fair amount of the cabinetry work on Weebles and I liked his work a lot. Very methodical worker.

There are several ribs visible now. This is the worst of them - where the floor timber rests has destroyed the rib. You can see my finger through the rotted section. I count 14 ribs that will need repair or replacing. In all candor, because the planks can be removed, this is time consuming but not the end of the world. I would have thought a boat built by a respectable yard in Canada would have stiffer ribs. Now I'm eager to see how Malahide trawlers are built - I recall ads for them touting the heavy construction. It means something to me now.

2. Other boats in the yard that caught my eye.

Almuminum fishing boat (herring boat????). What caught my eye was the way the zincs are mounted - very serviceable. And well protected to prevent lines from catching.

Same boat but a week ago before it was painted. Note the cage around the prop to help keep lines clear.

72-foot Marquis go-fast boat. La Costa painted the hull and the radar/KVH domes. They also serviced the props and rudders. It has a huge hydraulic swim platform that I'm sure could support the entire Corona Girls Volleyball Team. Second pic is being buffed - will be launched in a day or two.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Thursday, January 26th. 4-5 days from splash.

Continues to be a full-court press on Weebles. Monday looks pretty firm for launch. Orlando will be aboard to test systems. I am mostly interested in seeing the Stabilizers operate - they were inoperable on last sea trial several months ago.

PICTURES

1. Non-Skid Looks great. AlexSeal makes a non-skid granule that is mixed with their paint and sprayed. Very nice, consistent coating.

2. Three colors of Weebles. The hull-gate is a good place to see the white and two shades of grey that comprise Weebles. The caprails were originally mahogany. One of the Nordhavns I delievered was one of the very last N46's built, circa 2002 or so. It had encapsulated caprails and I was in love. Not only for maintenance reasons, but I thought they looked great. BTW - the hull-gate used to be an out-swing which was dangerous and inconvenient. The hinges were lift-off so if the door caught on a dock, it would launch into the water.

3. Last work items. Orlando started installing a few last minute items. External speaker for loud-hailer, air horn, and I decided to go with a Cerbo GX monitor system for solar to solve bluetooth issues. We'll see if its good money after bad....

4. Interior still a mess. Probably won't get cleaned-up until tomorrow, after the aforementioned install stuff is complete. But it's starting to look like a real boat -

5. Cruiseport Marina. Weebles will berth at Cruiseport Village Marina, a 10-min walk to Centro (downtown); and a 15-min walk to the boatyard. I stopped by yesterday to personally apologize for the any delays. There are two viable marinas in Ensenada. The other is Marina Coral where Ksanders and his Bayliner 4788 stayed a couple months ago. Coral is connected to a full service hotel and offers resort-style amenities. To my tastes, its a bit far from Centro, plus it's popular with gringos so its sort of a walled-garden. My slip rent at Cruiseport will be $450/mo - Coral would be about 10%-15% higher so negligible - it is a very nice marina.

6. Gaspars Barber Shop (not me in chair). I have had my haircut a handful of times from three different barbers. There seems to be a theme: they were all deported from the US. All did time in some sort of jail or detention likely for gang affiliation. All found God. And all have been good guys who give a riteous haircut. I've stuck with Gaspar for a while now - he does a neck massage at the end that just melts me into his chair. He uses one of the old fashioned Oster massagers with that has springs for bands around his hands. $140 pesos, around $7.50 USD.

Continues to be a full-court press on Weebles. Monday looks pretty firm for launch. Orlando will be aboard to test systems. I am mostly interested in seeing the Stabilizers operate - they were inoperable on last sea trial several months ago.

PICTURES

1. Non-Skid Looks great. AlexSeal makes a non-skid granule that is mixed with their paint and sprayed. Very nice, consistent coating.

2. Three colors of Weebles. The hull-gate is a good place to see the white and two shades of grey that comprise Weebles. The caprails were originally mahogany. One of the Nordhavns I delievered was one of the very last N46's built, circa 2002 or so. It had encapsulated caprails and I was in love. Not only for maintenance reasons, but I thought they looked great. BTW - the hull-gate used to be an out-swing which was dangerous and inconvenient. The hinges were lift-off so if the door caught on a dock, it would launch into the water.

3. Last work items. Orlando started installing a few last minute items. External speaker for loud-hailer, air horn, and I decided to go with a Cerbo GX monitor system for solar to solve bluetooth issues. We'll see if its good money after bad....

4. Interior still a mess. Probably won't get cleaned-up until tomorrow, after the aforementioned install stuff is complete. But it's starting to look like a real boat -

5. Cruiseport Marina. Weebles will berth at Cruiseport Village Marina, a 10-min walk to Centro (downtown); and a 15-min walk to the boatyard. I stopped by yesterday to personally apologize for the any delays. There are two viable marinas in Ensenada. The other is Marina Coral where Ksanders and his Bayliner 4788 stayed a couple months ago. Coral is connected to a full service hotel and offers resort-style amenities. To my tastes, its a bit far from Centro, plus it's popular with gringos so its sort of a walled-garden. My slip rent at Cruiseport will be $450/mo - Coral would be about 10%-15% higher so negligible - it is a very nice marina.

6. Gaspars Barber Shop (not me in chair). I have had my haircut a handful of times from three different barbers. There seems to be a theme: they were all deported from the US. All did time in some sort of jail or detention likely for gang affiliation. All found God. And all have been good guys who give a riteous haircut. I've stuck with Gaspar for a while now - he does a neck massage at the end that just melts me into his chair. He uses one of the old fashioned Oster massagers with that has springs for bands around his hands. $140 pesos, around $7.50 USD.

How did they do nonskid? Did they roll paint, spray material, then roll paint? Is it Awlgrip?

Awlgrip does make a texture to use with their paint. It’s called axltex. I used it on the foredeck last summer. You can mix it in the paint, or do what I did and roll out the paint, broadcast the granules as evenly as possible. Let it sit overnight. Sweep or vacuum up the excess and paint another coat. Very happy with it.

- Joined

- May 11, 2019

- Messages

- 3,447

- Location

- United States

- Vessel Name

- Muirgen

- Vessel Make

- 50' Beebe Passagemaker

Peter, am I missing something? That pic of the Cerbo GX and the Victron Solar Charge Controller appear to be mounted to a fuel tank?!? I'm assuming that because of what appear to be inspection ports on either side of the Victron items. Where am I going wrong here? Boat looks great! Hope splash happens on schedule!

Hippocampus

Guru

- Joined

- Jul 27, 2020

- Messages

- 3,925

- Location

- Plymouth

- Vessel Name

- Hippocampus

- Vessel Make

- Nordic Tug 42

All the best. Just glad you had fun doing this refit. Ours was do one thing and find another. Still finding some small stuff but doable by us not involving a yard. The moment a boat is Bristol fashion is a moment to truly cherish. We have a very small gasket leak on the Cummins. Not even enough to require being worried about checking oil more frequently than usual. But it bothers me so will replace the gasket next haul. Returning to the boat in two days. Be interesting to see what we find but expect after a going over by a diver we’ll be off and running. Sure you can’t wait to do the same. What are your plans. Cruise locally for awhile or head north? You now have a boat worth showing off and make all of us envious. Personally don’t care about that. Rather love the self satisfaction of a Bristol boat and a job welll done.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Fiberglass fuel tanks are blocked in with 2x3s with 3/4" plywood facia as a breadboard to mount equipment.Peter, am I missing something? That pic of the Cerbo GX and the Victron Solar Charge Controller appear to be mounted to a fuel tank?!? I'm assuming that because of what appear to be inspection ports on either side of the Victron items. Where am I going wrong here? Boat looks great! Hope splash happens on schedule!

The clean out ports you see are sort of interesting. They are end caps for high pressure oilfield fracking pipe bolted on to a pipe flange that was fiberglassed into the tank so it stands fairly proud off the side wall of the tank. This means the bolts are actually entirely on the outside of the tank - there are no through wall penetrations for fasteners. The corrosive nature of fracking liquid means fiberglass is ideal. As you can. Imagine, given their size due to fracking pressures, the bolts were quite expensive.

Glad you have a happy ending to your Victron story. So much of life is simply finding the right person.

Peter

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

McQueen Update - Last one for a while

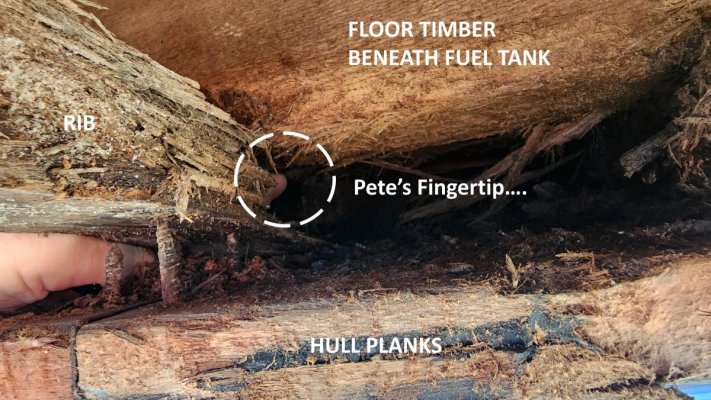

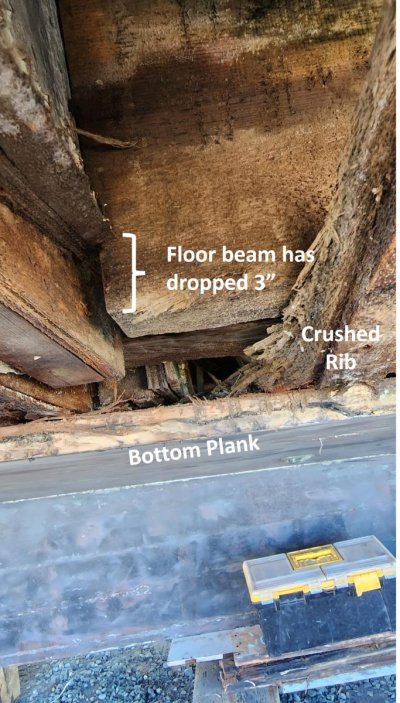

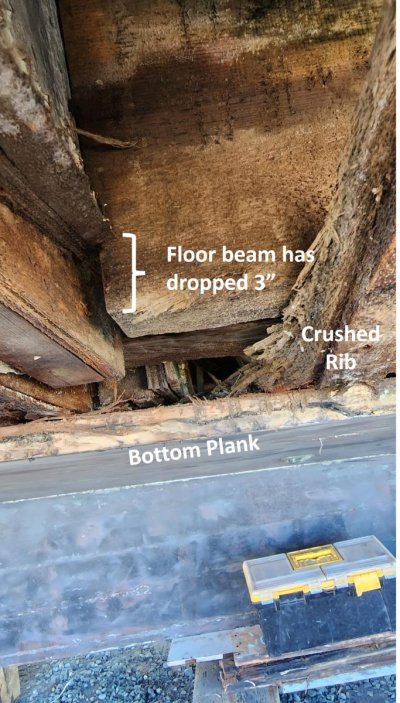

As mentioned, the fuel tanks - saddle tanks totaling 1100g - are nearly full, about 4000 lbs each including weight of tank. A heavy floor beam runs fore/aft beneath the tank supporting it across 15-ribs. The ribs are more rotted than I had iniitally believed. With the planking removed, the severely compromised ribs have given way.

Knowing how much Felipe has gotten done since Saturday - probably 40-hours of work plus another 15-hours from helpers, my guess is the work will end up with about 400 hours of repair if nothing else comes up. I don't know his rate, but would guess it to be in the $20/hr range - affordable compared to $125/hr just 80-miles north in San Diego.

Not sure there will be much more to update on this, but one thing I have certainly learned is when folks talk about buying a wooden boat, you really need a surveyor who has spent quality time building and evaluating wood boat construction - the infrastructure is seriously different than any other type of boat construction. I think it important to ask not just whether they will survey a wooden boat, but have they ever worked on them and to what extent.

PICTURES:

Floor beam beneath the tank. The large light colored beam runs fore and aft and supports the tank (about 500 gals diesel in the tank).

Here is the same beam from a different angle and captions.

Another picture of crushed ribs. It's interesting how it was originally constructed. The rib itself is about 2"x2" with a large wedge at the chine log. In hindsight, the 2"x2" rib is too light - it should have been at least 2"wx4" h and would have added little to the overall cost of the original boat.

Felipe using a removed rib-end and measuring patterns for replacement ribs. Wood is 8/4's Mahogany which is running just under $10 USD per board foot. Replacement fasteners in 316 SS are running about $1/ea, and about 800-1000 will be needed.

As mentioned, the fuel tanks - saddle tanks totaling 1100g - are nearly full, about 4000 lbs each including weight of tank. A heavy floor beam runs fore/aft beneath the tank supporting it across 15-ribs. The ribs are more rotted than I had iniitally believed. With the planking removed, the severely compromised ribs have given way.

Knowing how much Felipe has gotten done since Saturday - probably 40-hours of work plus another 15-hours from helpers, my guess is the work will end up with about 400 hours of repair if nothing else comes up. I don't know his rate, but would guess it to be in the $20/hr range - affordable compared to $125/hr just 80-miles north in San Diego.

Not sure there will be much more to update on this, but one thing I have certainly learned is when folks talk about buying a wooden boat, you really need a surveyor who has spent quality time building and evaluating wood boat construction - the infrastructure is seriously different than any other type of boat construction. I think it important to ask not just whether they will survey a wooden boat, but have they ever worked on them and to what extent.

PICTURES:

Floor beam beneath the tank. The large light colored beam runs fore and aft and supports the tank (about 500 gals diesel in the tank).

Here is the same beam from a different angle and captions.

Another picture of crushed ribs. It's interesting how it was originally constructed. The rib itself is about 2"x2" with a large wedge at the chine log. In hindsight, the 2"x2" rib is too light - it should have been at least 2"wx4" h and would have added little to the overall cost of the original boat.

Felipe using a removed rib-end and measuring patterns for replacement ribs. Wood is 8/4's Mahogany which is running just under $10 USD per board foot. Replacement fasteners in 316 SS are running about $1/ea, and about 800-1000 will be needed.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Friday, January 27 2023. Weebles is close.....

Late yesterday afternoon, Alberto turned to me and said "Peter, what else?" I couldn't think of much. There is still some residual buffing, and Orlando is still working on some electrical installs (Victron), and I decided this morning that the small error on how the flybridge MFDs were placed is not something I can live with. So Monday should indeed be the day.

Today is San Diego Day. I have some mail to pickup, I sold some stuff that needs to be shipped, my sewing machine is ready, and some odd parts to install a second deck washdown outlet in the aft cockpit area (Newfound Metals makes a clever flush-mount fitting HERE. I may have an extra one for sale if anyone's interested).

Pictures of minor items:

Ladder to Flybridge is in place.

Although this shows the propane locker unfinished, it is indeed complete with solenoid and bottles installed. It has not been tested yet.

New Vulcan anchor is in-place

Small pull-out bar. This cabinet beneath the lower helm seat housed the brain-box from the original Vosper Mini-Fin stabilizers. I decided on a bit of frivolity with a pull-out bar made from scrap GPO3 fiberglass and sprayed.

Here's the girl near sunset yesterday. I found an old picture to compare. I have some other before/after pictures I'll post in the near future.

Late yesterday afternoon, Alberto turned to me and said "Peter, what else?" I couldn't think of much. There is still some residual buffing, and Orlando is still working on some electrical installs (Victron), and I decided this morning that the small error on how the flybridge MFDs were placed is not something I can live with. So Monday should indeed be the day.

Today is San Diego Day. I have some mail to pickup, I sold some stuff that needs to be shipped, my sewing machine is ready, and some odd parts to install a second deck washdown outlet in the aft cockpit area (Newfound Metals makes a clever flush-mount fitting HERE. I may have an extra one for sale if anyone's interested).

Pictures of minor items:

Ladder to Flybridge is in place.

Although this shows the propane locker unfinished, it is indeed complete with solenoid and bottles installed. It has not been tested yet.

New Vulcan anchor is in-place

Small pull-out bar. This cabinet beneath the lower helm seat housed the brain-box from the original Vosper Mini-Fin stabilizers. I decided on a bit of frivolity with a pull-out bar made from scrap GPO3 fiberglass and sprayed.

Here's the girl near sunset yesterday. I found an old picture to compare. I have some other before/after pictures I'll post in the near future.

Pocoron

Member

- Joined

- Nov 6, 2020

- Messages

- 15

- Vessel Name

- Just Us 2

- Vessel Make

- Bayliner 4788

Peter, thanks for posting your journey through this refurb. It has been appointment viewing for me. Well written and lots of photos!

It is posts like this and members such as yourself that makes this a wonderful site.

Ron

It is posts like this and members such as yourself that makes this a wonderful site.

Ron

backinblue

Guru

- Joined

- Jan 29, 2019

- Messages

- 3,937

- Location

- USA

- Vessel Name

- Blue Moon

- Vessel Make

- Mainship Pilot 355

Peter, just curious if you'd care to share the time and costs involved for the entire project. Completely understandable if you'd rather not. I'm really only asking out of curiosity. Looking forward to some of the final pictures post-launch.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,242

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

I'll start a new thread with some general costing. I stopped counting a while ago, and with the Hack Team screw ups and repairs, a bit difficult. But I can get some decent info.Peter, just curious if you'd care to share the time and costs involved for the entire project. Completely understandable if you'd rather not. I'm really only asking out of curiosity. Looking forward to some of the final pictures post-launch.

Peter

Similar threads

- Replies

- 39

- Views

- 2K

Latest posts

-

-

-

Fixing boats in Exotic Places - are new boats really that bad?

- Latest: Hippocampus

-

-

-

-

-