If the wind is howling or the tide rushing and either or both are pushing you off the dock....trying to use a midship spring can be hard....so I don't do it.

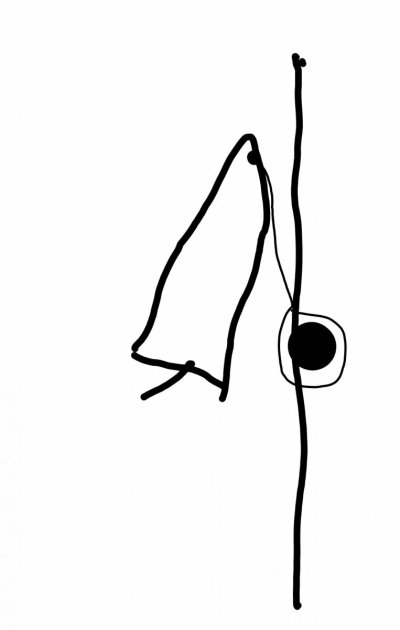

I ease the bow up with a line made fast to the bow, shorter than the length of the boat but nearly so, drop the other end with a loop over a cleat about where I expect the stern to wind up.

Generally, the wind/current is holding you off, but the effect is slow if directly on the bow, you usually have overhang or flare to help so it is not a rush job.

Even if blown well away from the dock, with a single and no thruster, you can now head in the general direction of the dock pointing the bow slightly in the direction that you ultimately want it.

You use just enough power to keep tension and enough rudder turned away from thw dock to allow the spring to allow the boat to swing in parallel to the dock. When the stern bumps the dock, time for the stern line.

A bow line can be added when the safest means is determined for your vessel.

Works for twins if the boat doesn't want to twist fast enough or the wind/current is just too much to lay alongside.

Paul,

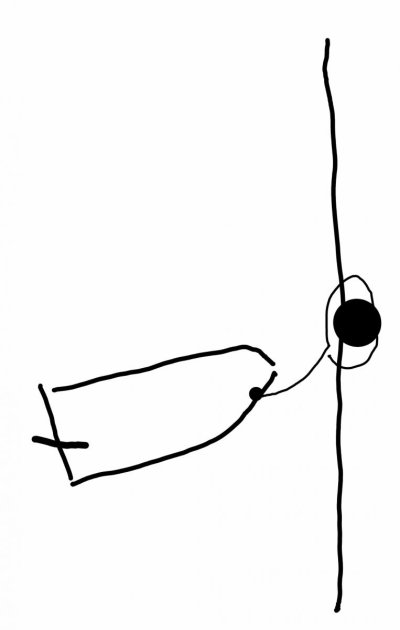

A diagram would be great, but do I understand this:

To get the loop end to a cleat, you would already be at some angle to the dock (trying to head into the wind as best you can. By the time you get back to the helm you could be not quite 90d to the dock, so you could be sticking out the length of the boat plus the length of the line.

And from that point you put the rudder away from the dock (if you're docking bow in, port side, you'd turn to starboard, and then just add enough power to slowly swing the boat to starboard up to the dock where you could tie up the stern line.

Am I missing anything?

Seems like it would work if you had no obstructions or boats to your starboard?