Answering the questions above. Thanks for asking, Greg QS!

This is the starboard engine on a twin 42 foot north Pacific, 2005.

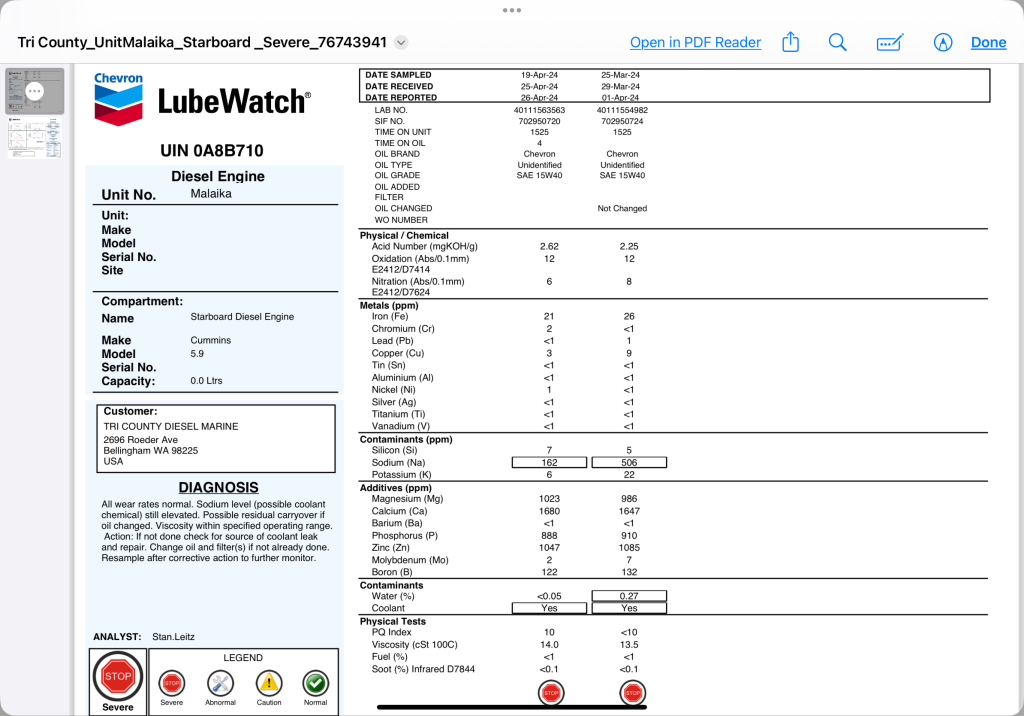

The only major part that has been changed on the engine is the water pump. The engines have been running perfectly.

No overheats, but the boat is in charter, and was out two weeks last summer and has not had significant time on the water since.

About typically runs 185° to 190°, and is turbo cooled

There’s a little bit of white smoke in the exhaust, but it is pretty clear

There was no significant visual issue with the oil that we took on either test (not milky in any way)

Here’s what was done in the engine service, when we took the oil sample:

Take & submit gear oil sample, Change lubrication oil, Install new lubrication oil filter, Clean Racor bowls, Install new primary fuel filters, Install new secondary fuel filters, Change gear oil, Clean gear screens, Install new impellers, Check belt tension, Install new zincs on all heat exchangers/coolers, Check coolant concentration, Clean air filter, Clean sea strainer, Clean engine sump pan, Check throttle & shift controls, pins & cables at helm, flybridge, & engines; lube, Inspect wiring, wiring harnesses, connections & starter motor for corrosion, chafe & tightness; service as required, Spray electrical components with BOE SHIELD when touch-up paint is dry, Inspect all bolts, nuts, hose clamps & engine fittings; Inspect oil centrifuge and/or bypass filter

No oil in the coolant, and no significant burn of coolant

The boat is running well, and we were ready for a great summer! Hoping we dont find ourselves tearing it down! Thank you for the insights and support!