Hi

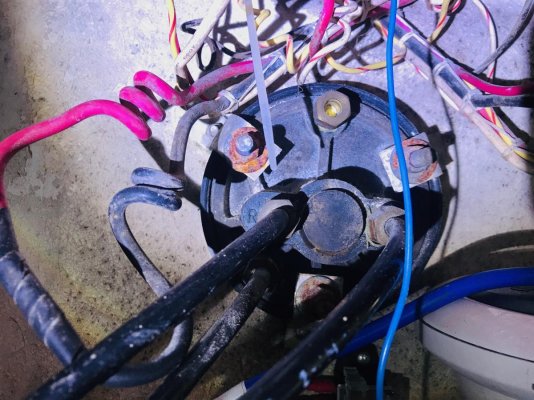

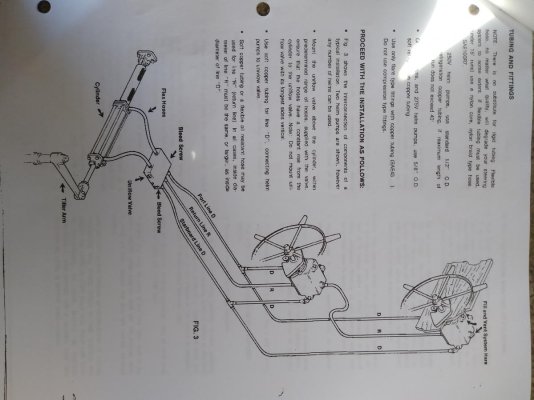

We have a Puget Sound 34, newly purchased, and we are having problems with the hydraulic steering. Its a three pipe rig with a Seastar ram and lower helm and a rather older (unmarked - see photos) upper helm - possibly the original. I set up a bubble purge system and started pumping the upper helm in a clockwise direction - three fast turns and then a pause to let the bubbles out and the oil drain in. This was very rewarding to start with. Lots of bubbles appearing immediately when I stopped turning. Although, strangely, the amount of oil in the suspended bottle only went down a very small amount. Fast forward to around three hours later, exhausted by now, and still doing the same and still the same amount of bubbles appearing every time. That's around a good litre of air (a quart) out at a rough guess, but at most, only .2 litre of oil that went in. There are no leaks in the system.The only thing I can think of is that the helm pump is sucking air in from somewhere? Has anyone else had this experience? Or should I just keep pumping? If anything now, the steering is worse than when I started.

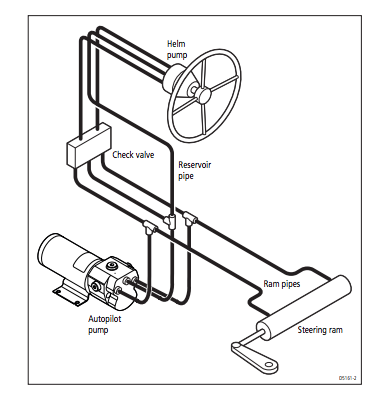

The only strange thing I can find in the set up is that the check valve (three pipes on one side and two on the other) is set up the opposite way to that shown on the Seastar web site (diagram attached). The three pipes are on the helm pump side of the valve, rather than on the ram side. Although this doesn't look like it has been disturbed for a long time (see attached photo), so it was probably originally installed that way. Does this matter?

Any help or advice would be most gratefully received!

We have a Puget Sound 34, newly purchased, and we are having problems with the hydraulic steering. Its a three pipe rig with a Seastar ram and lower helm and a rather older (unmarked - see photos) upper helm - possibly the original. I set up a bubble purge system and started pumping the upper helm in a clockwise direction - three fast turns and then a pause to let the bubbles out and the oil drain in. This was very rewarding to start with. Lots of bubbles appearing immediately when I stopped turning. Although, strangely, the amount of oil in the suspended bottle only went down a very small amount. Fast forward to around three hours later, exhausted by now, and still doing the same and still the same amount of bubbles appearing every time. That's around a good litre of air (a quart) out at a rough guess, but at most, only .2 litre of oil that went in. There are no leaks in the system.The only thing I can think of is that the helm pump is sucking air in from somewhere? Has anyone else had this experience? Or should I just keep pumping? If anything now, the steering is worse than when I started.

The only strange thing I can find in the set up is that the check valve (three pipes on one side and two on the other) is set up the opposite way to that shown on the Seastar web site (diagram attached). The three pipes are on the helm pump side of the valve, rather than on the ram side. Although this doesn't look like it has been disturbed for a long time (see attached photo), so it was probably originally installed that way. Does this matter?

Any help or advice would be most gratefully received!

$00.02

$00.02