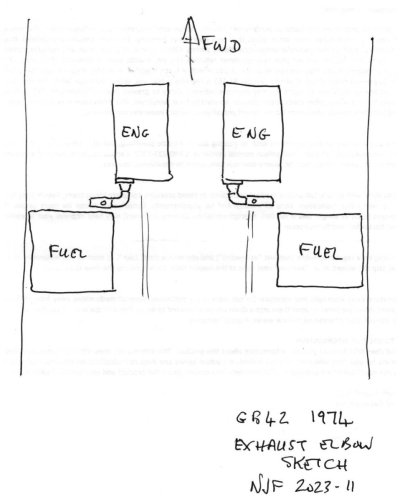

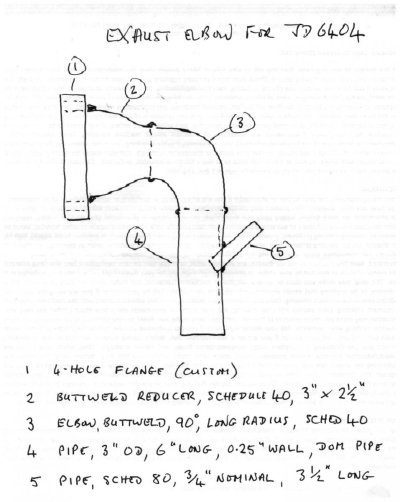

Since cannot find off-the-shelf replacement exhaust mixing elbows for my Ammarine 6404 diesels am going to have custom ones made.

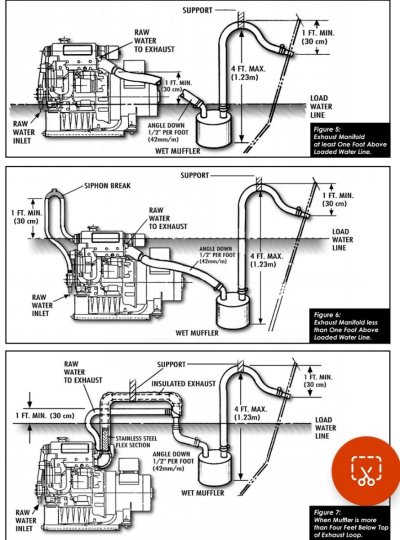

Are there any rules-of-thumb on the height above waterline that are applicable?

Any other rules or guidelines I should be aware of?

Existing ones extend higher than the exhaust manifolds so if an internal leak ever developed raw water could get back down into the engine.

Instead of rising up above the engine, am thinking of exiting exhaust maniford and then immediatley dipping down below its height so any future leak would be impossible to get back up into the engine.

Any thoughts or advice from folks fluent and expert on this topic will be appreciated.

Thank you

Are there any rules-of-thumb on the height above waterline that are applicable?

Any other rules or guidelines I should be aware of?

Existing ones extend higher than the exhaust manifolds so if an internal leak ever developed raw water could get back down into the engine.

Instead of rising up above the engine, am thinking of exiting exhaust maniford and then immediatley dipping down below its height so any future leak would be impossible to get back up into the engine.

Any thoughts or advice from folks fluent and expert on this topic will be appreciated.

Thank you