FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

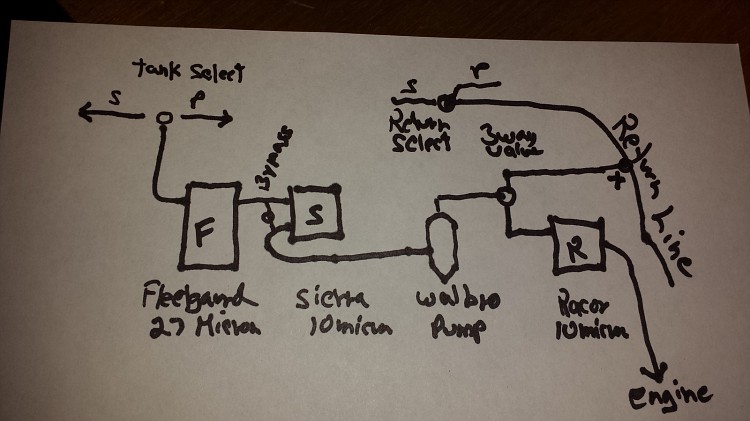

It is normal that liquid pumps push better than they pull.

The use of a rubber bulb is a far better idea than any electric pump if needed before a filter bank.

The electric pump can easily mix any water with the fuel making the filters work much harder.

The rubber hand pump will do less shredding and mixing , so is probably a better installation, although an electric pump would be fine if pulling rather than pushing.

The use of a rubber bulb is a far better idea than any electric pump if needed before a filter bank.

The electric pump can easily mix any water with the fuel making the filters work much harder.

The rubber hand pump will do less shredding and mixing , so is probably a better installation, although an electric pump would be fine if pulling rather than pushing.