capran

Senior Member

- Joined

- Apr 11, 2022

- Messages

- 198

- Vessel Name

- Honu

- Vessel Make

- Helmsman 38/Mariner Saville 37

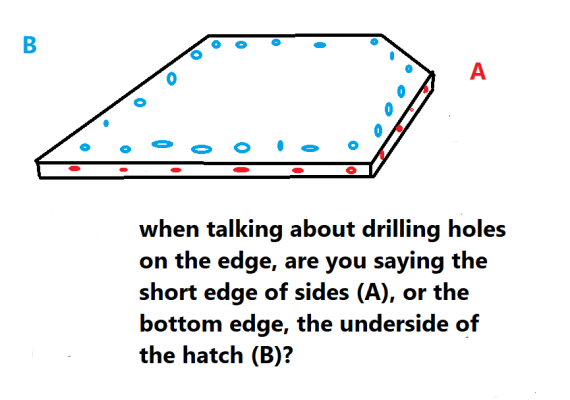

Last fall during layup noticed anchor well hatch had cracking and some water coming out of the crack. took it home and dried it out, but not sure repair is

in my skillset. there's not much looseness to the cracking. Before taking it in to see if North Harbor Marine can do the repairs, I'd appreciate any input from the Forum.

in my skillset. there's not much looseness to the cracking. Before taking it in to see if North Harbor Marine can do the repairs, I'd appreciate any input from the Forum.

in my skillset. there's not much looseness to the cracking. Before taking it in to see if North Harbor Marine can do the repairs, I'd appreciate any input from the Forum.

in my skillset. there's not much looseness to the cracking. Before taking it in to see if North Harbor Marine can do the repairs, I'd appreciate any input from the Forum.