- Joined

- May 11, 2019

- Messages

- 3,447

- Location

- United States

- Vessel Name

- Muirgen

- Vessel Make

- 50' Beebe Passagemaker

Our new to us boat is a 50’ Robert Beebe designed Passagemaker. The original owner purchased and installed a Gardner 8LXB medium speed engine, which is a massive engine! He coupled that to a Hundested, 3 blade, Variable pitch (VP) propeller. The VP actuating mechanism is in line with the propshaft, aft of the gear reduction.

The use of VP allows for several benefits.

So, for normal cruise, we select an engine RPM of 1400, and pitch the blades to obtain 7.5kts through the water.

Boat weighing approximately 85k lbs, with half fuel, half full fresh water, holding tanks empty and owners stuff on board, and running the 12kw generator, we burn right on 2.4 gallons/hr which equates to 3.125 nautical miles/gallon. Not to shabby for an 85,000 lb boat!

With full fuel tanks holding 2,100 us gallons, that is 875 running hours, with a max cruise range (no reserve) of 6562 nautical miles. So, in theory, we could go from Seattle, WA to Key West, FL without refueling. Then we’d have to take out a mortgage to refuel the tanks to full!

Since the engine driven hydraulic pump is also driving the 12kw, 120v AC generator, we have all the AC power we wish underway, without having to run the separate, standalone Isuzu 4LE2 auxilary engine, which drives a hydraulic pump which provides hyd power either to the AC generator, bow thruster, or a hyd motor that provides “get home” capability in the event the main engine fails.

The Gardner engine, new in 1978, was just north of $60k. The Hundested VP prop, shaft, and actuating mechanism is currently selling for around $40k to $50k, plus shipping from England.

The boat also came with a spare blade for the propeller, but it has never been needed.

This is a unique application of engine and drive train that I have not run across before, but since the initial cost was wrapped up in the purchase price, it didn’t end up costing any more than a comparable setup.

[FONT="]We do have a little more maintenance required due to the VP actuating mechanism requiring periodic oil changes. And the VP propeller requires disassembly and lubing, I believe every 2000 hours or so, which can be accomplished during scheduled haul out with minimal tools. Overall, we’re really satisfied with the setup, and look forward to many years of use![/FONT]

[FONT="]

[/FONT]

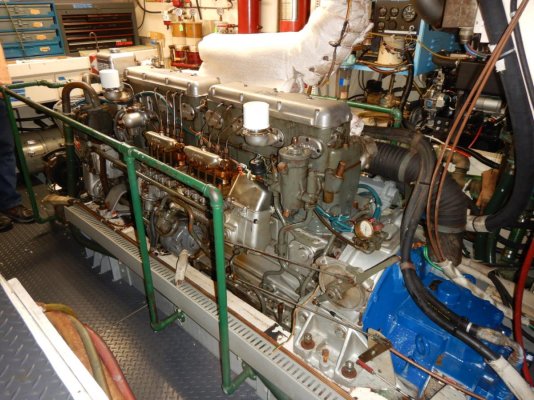

[FONT="]Attached pics: Gardner 8LXB, VP propeller, and controls[/FONT]

[FONT="]On the controls, the left hand lever is the gear reduction engage/disengage, only neutral and forward are used. The middle lever is engine throttle, and the right hand lever is the blade pitch for neutral, fwd and rev.

[/FONT]

The use of VP allows for several benefits.

- You can run your engine in it’s most economical RPM, while using the blade pitch to select the speed you wish to travel.

- You can go from forward to reverse rapidly, with no need to reduce throttle, wait for engine speed to reduce, shift to neutral, then reverse, then bring up engine RPM again for reverse.

- If, as in our case, your boat has a hydraulic bow thruster, with an engine driven hyd. pump, you can be sitting at the dock, or wherever, and utilize the bow thruster, taking advantage of full operating pressure/volume while not moving since the engine is already at rpm. The same would hold true if you had a hydraulic anchor windlass, which, sadly, we do not.

- You start your main engine, and once it’s warm:

- Shift the reduction gear into gear (it’s a standard gear reduction with both forward and reverse, but in this case, reverse is not utilized).

- Using the VP selector, you pitch the blades, pushing forward to go forward, and pull back to go in reverse. The blade pitch varies depending on how much you push/pull the lever.

So, for normal cruise, we select an engine RPM of 1400, and pitch the blades to obtain 7.5kts through the water.

Boat weighing approximately 85k lbs, with half fuel, half full fresh water, holding tanks empty and owners stuff on board, and running the 12kw generator, we burn right on 2.4 gallons/hr which equates to 3.125 nautical miles/gallon. Not to shabby for an 85,000 lb boat!

With full fuel tanks holding 2,100 us gallons, that is 875 running hours, with a max cruise range (no reserve) of 6562 nautical miles. So, in theory, we could go from Seattle, WA to Key West, FL without refueling. Then we’d have to take out a mortgage to refuel the tanks to full!

Since the engine driven hydraulic pump is also driving the 12kw, 120v AC generator, we have all the AC power we wish underway, without having to run the separate, standalone Isuzu 4LE2 auxilary engine, which drives a hydraulic pump which provides hyd power either to the AC generator, bow thruster, or a hyd motor that provides “get home” capability in the event the main engine fails.

The Gardner engine, new in 1978, was just north of $60k. The Hundested VP prop, shaft, and actuating mechanism is currently selling for around $40k to $50k, plus shipping from England.

The boat also came with a spare blade for the propeller, but it has never been needed.

This is a unique application of engine and drive train that I have not run across before, but since the initial cost was wrapped up in the purchase price, it didn’t end up costing any more than a comparable setup.

[FONT="]We do have a little more maintenance required due to the VP actuating mechanism requiring periodic oil changes. And the VP propeller requires disassembly and lubing, I believe every 2000 hours or so, which can be accomplished during scheduled haul out with minimal tools. Overall, we’re really satisfied with the setup, and look forward to many years of use![/FONT]

[FONT="]

[/FONT]

[FONT="]Attached pics: Gardner 8LXB, VP propeller, and controls[/FONT]

[FONT="]On the controls, the left hand lever is the gear reduction engage/disengage, only neutral and forward are used. The middle lever is engine throttle, and the right hand lever is the blade pitch for neutral, fwd and rev.

[/FONT]

Awesome

Awesome