Hi Tom

Having just gone through this with a FL120 I may be able to add a few things here. As was mentioned before, call Brian at American Diesel. He is THE expert on these engines, and all the info I'm repeating and parts I'm referencing came from him. AFAIK the bubbling is normal. Here are some things to think about:

1) There is a breather passage in the front of the expansion tank that tends to get clogged over time. There's no real way to unclog it. The solution is to install an overflow catch reservoir and a new filler neck. Here is a picture of the new filler neck ready for epoxy in.

https://photos.app.goo.gl/TtvFnrbHbAca8HZy5

The hose goes to a catch bottle and forms a system that basically circumvents the blocked overflow passage. As the engine heats up, natural expansion of the coolant causes it to overflow out. The idea behind this system is that a tube goes on that nipple to a low mounted catch tank, and it just forms a siphon so that any expelled excess is just sucked back in when the engine cools off again.

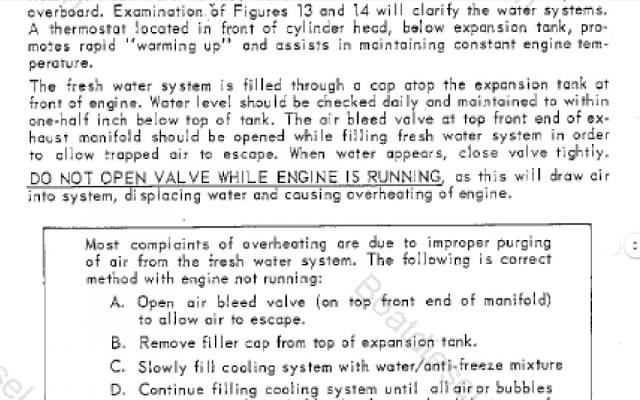

2) Others have mentioned bleeding it. That's a good idea also. The bleeder valve is located on the port side of the engine just aft of the expansion tank. It's that little petcock you can see in your video. With the engine running, open it a bit until you can feel fluid/air coming out, wait for a steady stream, then close it and then top the system off at the expansion tank.

3) 120 is very cool for these engines. You want 165-180 IIRC, measured at the #6 cylinder (all the way fore) on the block with an accurate IR gun. Frequently the gauges are not correct - mine wasn't - so while you are at it it's worth it to verify. Running cool is bad also, Brian says that the cylinders don't take their shape until they reach operating temperature, so it's important to run it gently until it reaches full operating temp. It's not like the old detroits where you just turn the key and bury the throttle.

Hope this helps some. I definitely recommend a call to Brian (not me) @ American Diesel in Virginia. Guaranteed you will learn something. Good luck!

Brian

May I ask all of you experienced and knowledgeable folks to take a look at my video of my motor running and the Coolant reservoir "Burping" and comment if this is "Normal"

And if it isn't I'd, sure be grateful for any constructive comments and suggestions as to where I can find the culprit......

Thanks

Tom McBride

Long Beach

Shoreline Marina.

https://drive.google.com/drive/folders/1FRLH4lPt2l-U2LKLyUI27h_mAYHtEXci?usp=sharing