Scottwb96

Senior Member

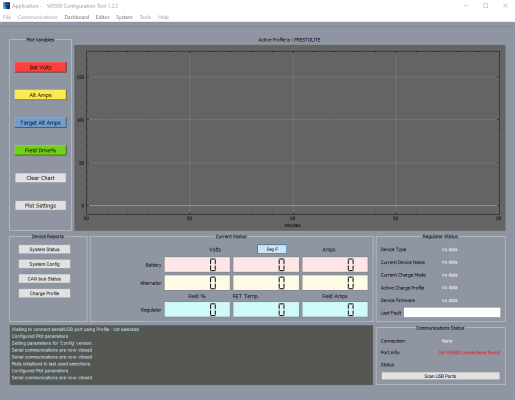

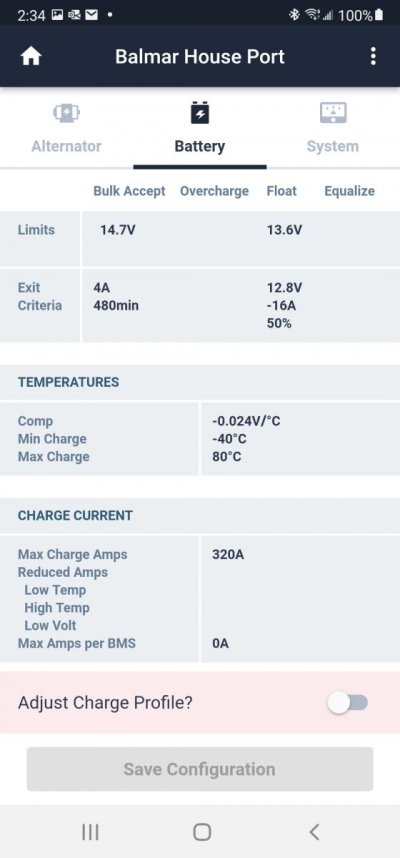

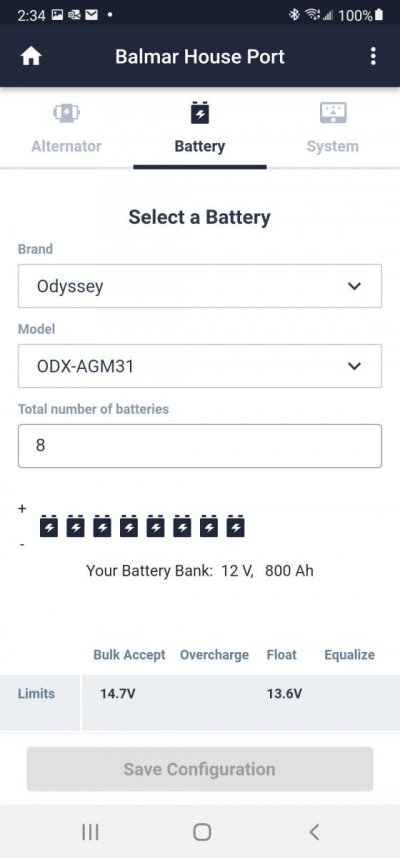

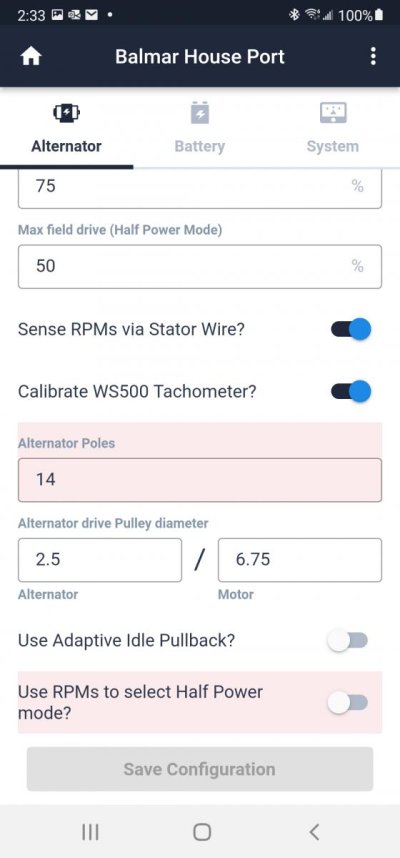

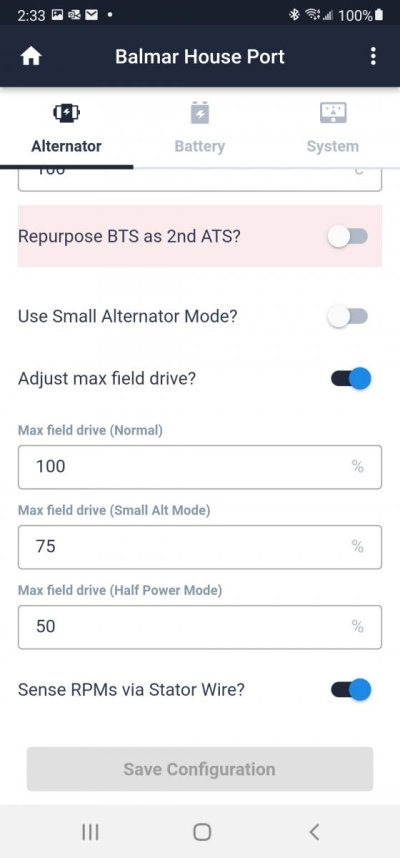

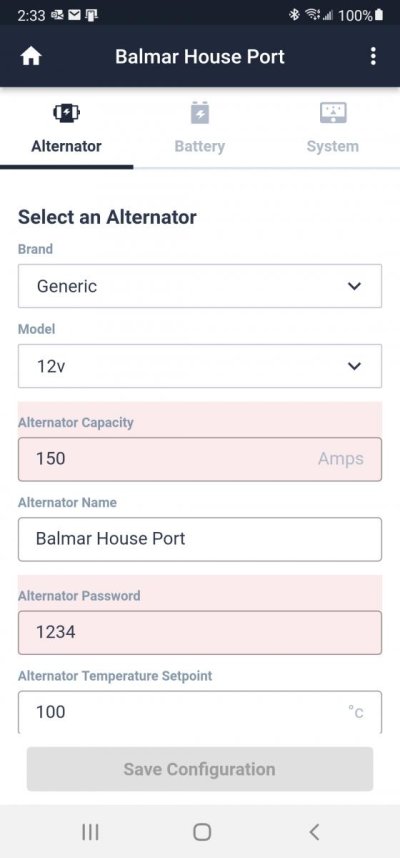

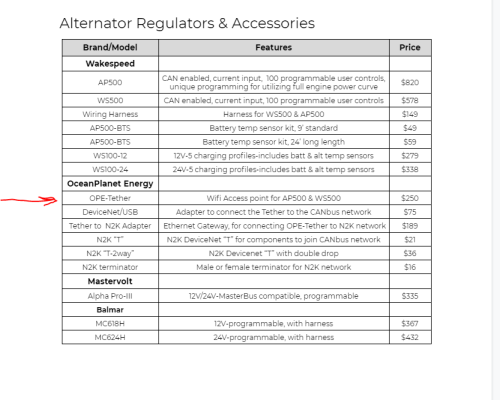

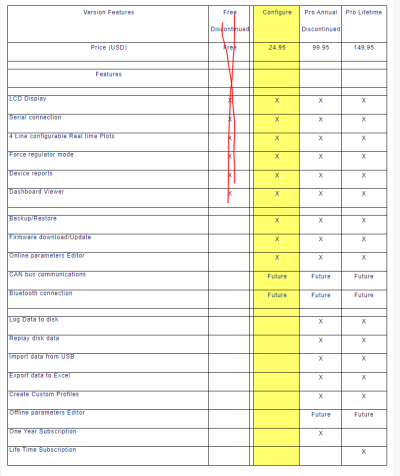

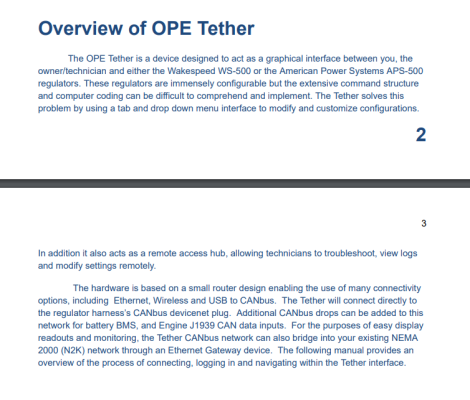

Not sure if you're using the Wakespeed programming tool or something else. The one designed by "Offgrid" (link below) is pretty impressive and lets you get super granular as well as see real-time output/monitoring of the device... Not at the boat right now, so can't show the real-time. But I can do it a bit later today if you're interested...

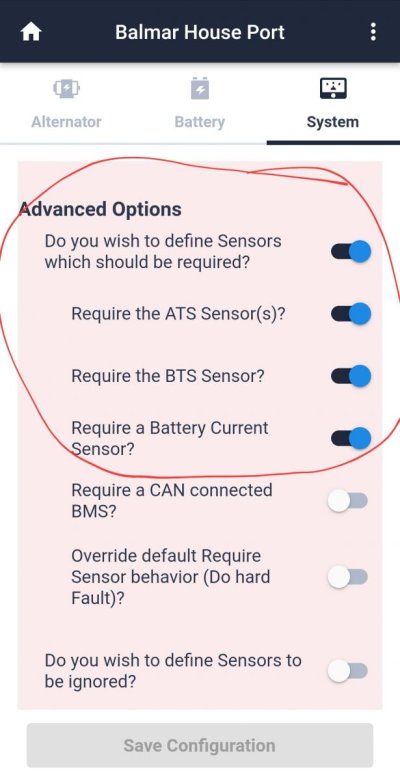

Also, I know you said you are confident that it's programmed correctly, but I would double/triple check that BOTH the battery and the alternator temp sensors are connected. As well as in the programming tool, that the boxes are checked to require their input...

https://www.offgridsoftwaresolution...tool-config-version-life-time-windows-64-bit/

Also, I know you said you are confident that it's programmed correctly, but I would double/triple check that BOTH the battery and the alternator temp sensors are connected. As well as in the programming tool, that the boxes are checked to require their input...

https://www.offgridsoftwaresolution...tool-config-version-life-time-windows-64-bit/