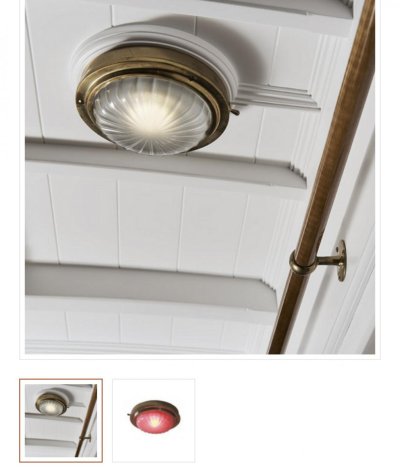

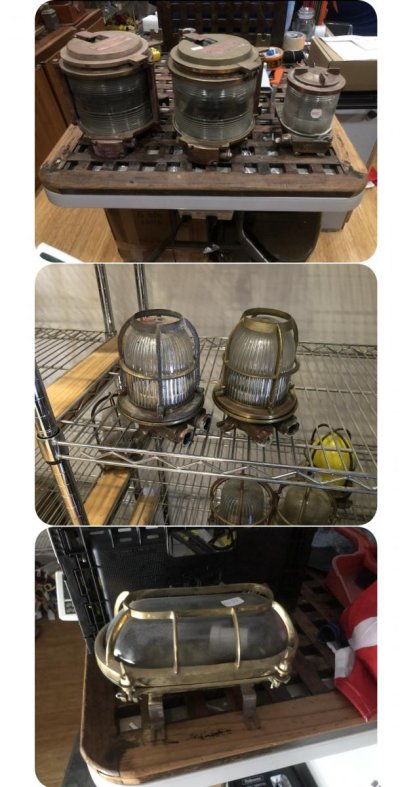

Hello, I recently purchased a 1990s custom steel hull boat. I noticed that on the internal living areas there is a mixture of both bronze, chrome and stainless steel fixtures (hinges, latches, light fittings, slide bolts, cupboard door knobs). I’m hoping to improve the aesthetics of the interior and i’m wondering if having a mixture of metals within the same interior areas is common? My initial thought was to replace it all with bronze fittings. Should i try to stick to one material only? (i’m not concerned about galvanic corrosion). The interior also has dark stained timber. Externally the majority of the fixtures are stainless steel welded

to the steel hull. I’m leaning towards replacing the internal fixtures with bronze, however i may be confusing the traditional bronze / timber style and applying it to a boat that it doesn’t match or suit. Any comments or feedback is appreciated.

to the steel hull. I’m leaning towards replacing the internal fixtures with bronze, however i may be confusing the traditional bronze / timber style and applying it to a boat that it doesn’t match or suit. Any comments or feedback is appreciated.