Roger Long

Senior Member

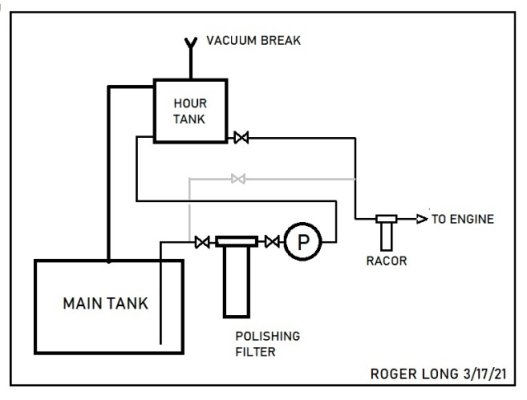

I've seen a lot of fuel polishing systems proposed here and elsewhere. I've gotten by without one on our current trawler but, when and if I get around to installing one, it will be like this one which simplifies retrofit issues and a lot of extra piping.

https://www.cruisingonstrider.us/images/Fuel_Polishing.pdf

https://www.cruisingonstrider.us/images/Fuel_Polishing.pdf