wkearney99

Guru

- Joined

- Feb 17, 2018

- Messages

- 2,164

- Location

- USA

- Vessel Name

- Solstice

- Vessel Make

- Grand Banks 47 Eastbay FB

Our EB47 has a pair of 10# propane canisters.

WTF are these things made out of that they're so 'ffing expensive to replace? $200-300 for aluminum? I mean, I get economies of scale and B.O.A.T. pricing, but really?

I may have one with a leak. It doesn't leak when screwed closed, but may when it's partially opened while connected to the boat's setup. I catch a whiff of the additive when I have one tank connected, vs no smell with the other one. We don't use the propane regularly, and I don't leave any tanks 'open' to the system. I screw the tank closed after every use. The cabinet for the tanks is outside, in the cockpit and is vented. I'm guessing the leak is just at the shut-off valve of the questionable tank, and that it only leaks enough to smell during the opening/closing of the valve on it. The smell is only at the tank, not at any other point along where the hose runs up to the galley.

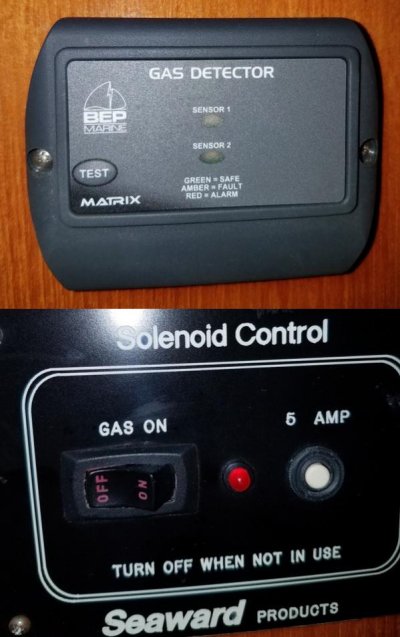

I don't have a close-up of the tank connecting setup. It's a 3' length of hose with a regulator and a gauge connected into what looks like a solenoid. The control for which is at the galley down below.

I'm expecting my plan to include replacing the hose/regulator setup that connects a tank to the solenoid. That doesn't appear to be made of anything unusual for portable propane setups.

Anyone done similar replacements and have suggestions?

WTF are these things made out of that they're so 'ffing expensive to replace? $200-300 for aluminum? I mean, I get economies of scale and B.O.A.T. pricing, but really?

I may have one with a leak. It doesn't leak when screwed closed, but may when it's partially opened while connected to the boat's setup. I catch a whiff of the additive when I have one tank connected, vs no smell with the other one. We don't use the propane regularly, and I don't leave any tanks 'open' to the system. I screw the tank closed after every use. The cabinet for the tanks is outside, in the cockpit and is vented. I'm guessing the leak is just at the shut-off valve of the questionable tank, and that it only leaks enough to smell during the opening/closing of the valve on it. The smell is only at the tank, not at any other point along where the hose runs up to the galley.

I don't have a close-up of the tank connecting setup. It's a 3' length of hose with a regulator and a gauge connected into what looks like a solenoid. The control for which is at the galley down below.

I'm expecting my plan to include replacing the hose/regulator setup that connects a tank to the solenoid. That doesn't appear to be made of anything unusual for portable propane setups.

Anyone done similar replacements and have suggestions?

And even if they are over 10 yrs old, a propane shop can recertify them for 5 yr stretches.

And even if they are over 10 yrs old, a propane shop can recertify them for 5 yr stretches.