BonesD

Senior Member

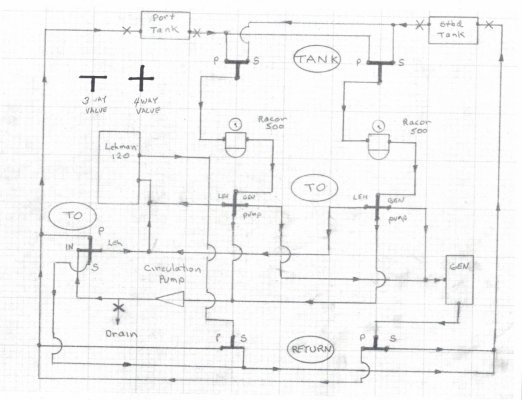

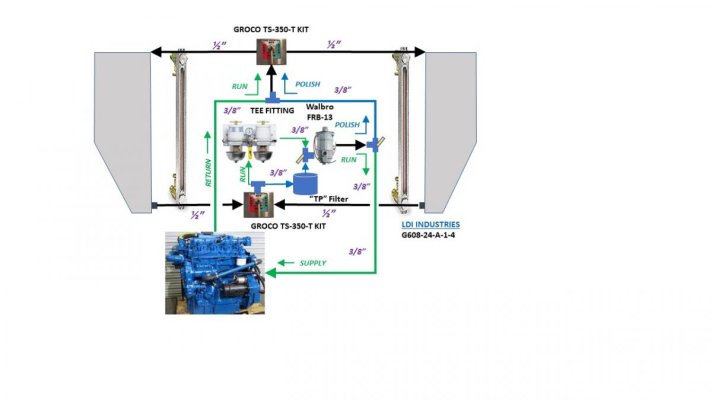

I’m interested in changing out my single Racor filter to a dual filter system with a vacuum gauge.

My engine is an old Perkins 4.236 diesel.

It only burns about a gallon per hour at cruising speed. I checked the return and at a 1000 rpms it was returning about 5 ounces every 60 seconds.

So if my math is right, 5 ounces x 60(minutes)=300 ounces or 2.34 gallons per hour on the return and and another gallon for fuel consumption the total per hour the filter is processing is only about 3 1/2 gallons per hour.

Does this sound right?

If so what Racor fuel filter:separators would be appropriate. Seems a waste to buy something that will process 160 gallons an hour.

I know a lot of folks opinions on the need for this differs but I have decided this is the way I would like to go.

Thanks

My engine is an old Perkins 4.236 diesel.

It only burns about a gallon per hour at cruising speed. I checked the return and at a 1000 rpms it was returning about 5 ounces every 60 seconds.

So if my math is right, 5 ounces x 60(minutes)=300 ounces or 2.34 gallons per hour on the return and and another gallon for fuel consumption the total per hour the filter is processing is only about 3 1/2 gallons per hour.

Does this sound right?

If so what Racor fuel filter:separators would be appropriate. Seems a waste to buy something that will process 160 gallons an hour.

I know a lot of folks opinions on the need for this differs but I have decided this is the way I would like to go.

Thanks