There is a bit more to unpack here. First pertains to journeyman-level tradesmen and their approach to their craft. Second is to the nature of project management. Third, general management philosophy. Finally, how this all plays out against dual axises of boatyard and Mexico.

Fine craftsman. Up-thread, I posted a YouTube showing a $3m restoration of a classic Nate Herreschoff one design. Done in Maine by a very reputable yard with every imaginable tool and shop facilities. Definitely highly skilled and exacting boatwrights. Definitely rare. And expensive. And not what I was looking for even if it was available. The level of skill I have retained is definitely adequate for my purposes, but if I had a Nordhavn with fine joiner work, I would not let them do the work if for no other reason but they simply do not have the tools to do such work (not boat related, but below is a cool video showing very tight tolerance joints).

Project Management. PM was a big part of my professional career in management consulting where I specialized in very large IT transformation projects. I managed projects, but was not a project manager if that makes sense. As a category, PM is perhaps the most misunderstood role, certainly in IT. Why? Because the perception is that it is primarily a scheduler and doesn't need to know all the other roles. The best PMs have a much deeper understanding of the project. My clients assigned their best and brightest to the projects I worked and yet I'd say about 5%-10% of them were decent PMs. But the ones that were good were worth their weight in gold. I just don't think that's a reasonable expectation at most boatyards (see: $3m restoration where the PM is clearly knowledgeable on all aspects).

Management Philosophy - near/dear to me as I had an inside view of so many large companies during my career. Several years ago I read the results of a study that compared charismatic leaders vs non-charismatic leaders. Steve Jobs, Lee Iacocca being the charismatic types of the day (think: Elon Musk these days). Although there were certainly examples of strong leaders doing exceptional work, what the study found was a dominant thread of under-performance. The leader essentially blocked-out the sun in meetings so they did not get the best collective wisdom of the team. My takeaway was to end more sentances with question marks than exclamation points.

Another example of management philosophy. I don't know the number today, but 20-years ago the "happiness" income was $75k/year, meaning that once you had that type of income, you could meet your general financial obligations and have a bit leftover for discretionary spending. Now, leaving the number aside, it makes sense to look at that type of threshold. How does this factor into management philosophy? There is a point where many/most people work for other reasons than just money. Not to say money is not important - this is America and it's how we keep score. But if you really want the best out of people, you need to motivate other sectors of their core being. Provide a sense of achievement. In a nutshell, how do you get people 'vested' in their work? Some of the most powerful statements in the professional work environment are "What is your best thinking?" Or "What's the right thing to do here?" Carrots vs sticks.

All of the above needs to adapt to local culture and custom - as the fly fishermen like to say, "Match the hatch." Again, reverting back to my management consulting days, you have to do that in professional life. I once rolled-off a project with Morgan Stanley in mid-town Manhattan onto a project with a subsidiary of McDonalds in the Chicago area where I immediately realized my sharp-elbowed approach needed refining. And then to Nvidia in Silicon valley where everyone wants a seat at the table. Doing work in Mexico (or any other place) is no different.

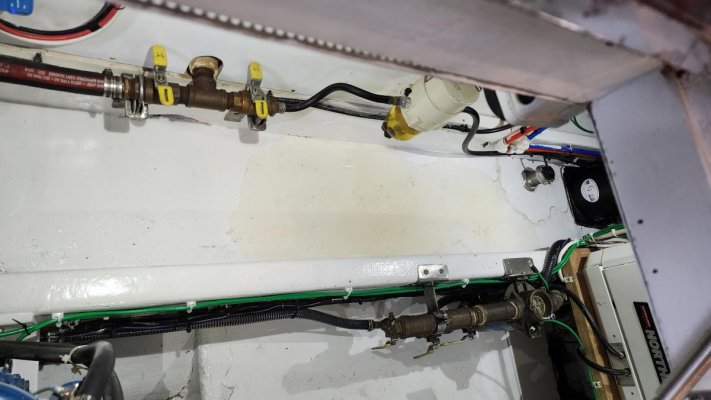

In the end, I find myself keeping the end in mind. I'm willing to lose a couple battles as long as the overall project is moving in a roughly forward motion. With exception of hull and engine, Weebles is essentially a new boat. The term 'refit' is used a lot on forums like this but has a lot of different meanings of depth and breadth of work (similar to "rebuilt engine"). When done, I'll call Weebles a 1970/2023 Willard 36.

If you've made it this far into this post, thanks for hanging with me.

Peter

Here is a YouTube video on some very fine woodworking joinerwork. This is not what you'll find in most boatyards, but you will find it in the better builder's yards