Duetto

Senior Member

- Joined

- Nov 18, 2016

- Messages

- 287

- Location

- United States

- Vessel Name

- GEM

- Vessel Make

- Mainship Pilot 34

hi all,

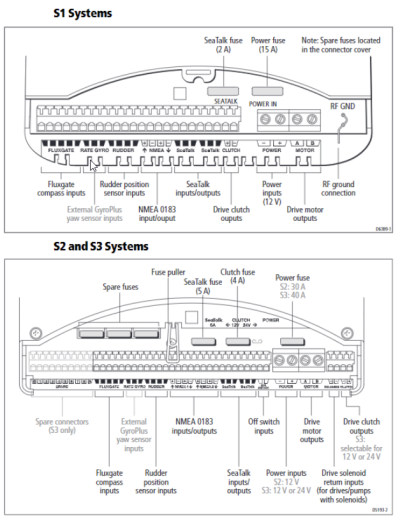

we have a 2003 pilot 34 ht which came w/o an autopilot. i'm thinking about installing one and have a couple of questions: 1) where did the factory physically place the pump? i'm thinking i'll put it on the shelf where sterring ram is mounted. 2) does anyone know if the wiring looms were standardized? the boat has the gyro compass and course computer.

any help is welcome.

we have a 2003 pilot 34 ht which came w/o an autopilot. i'm thinking about installing one and have a couple of questions: 1) where did the factory physically place the pump? i'm thinking i'll put it on the shelf where sterring ram is mounted. 2) does anyone know if the wiring looms were standardized? the boat has the gyro compass and course computer.

any help is welcome.