Now you have me totally confused.

In your first post #1,& in other early posts,you state that you have manual hydraulic steering.You show pics of a double Teleflex ram system & a Kobelt manual hydraulic helm with big steering wheel-7.5 turns lock to lock.

This all made sense.

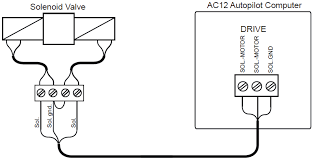

Now you show a pic of what appears to be a belt driven Vickers VTM 42 type pump,with attached autopilot electric solenoid valve & hydraulic reservoir tank. This pump,tank & solenoid assembly tells me that your boat is ready to connect an autopilot.

Do you have a Jog Steering switch? Is anything connected to the 4 wires coming out of the solenoid valve in above pic?

Len

Honestly, I am also confused now. Until you pointed out that I need a belt driven pump and expansion tank, I did not even think about this. Till now, I thought, I just had a manual hydraulic steering, without any pump.

So, I apologize. Unfortunately, there is not much documentation on this boat. I am learning about her, as I go. I am also new to pleasure boating and I am not a mechanic.

I will dig in more and see, if there is anything more about the existing hydraulic system? I know the boat has hydraulic steering, bow thruster, transmission, windlass. Perhaps, all these require a stronger pump? Perhaps an overhaul is due on the hydraulic system? I don't know.

My main concern as of now, the steering. I do need easier steering, because as a single guy, it is very important to steer fast and easy at docking. I just had a very iffy situation at the dock, last weekend. I don't want that happen again. I need to be able to move the wheel easy anytime.

If you think I have everything I need for better steering, I do need to figure out, how to troubleshoot the stiffness of the steering wheel. I have never dealt with hydraulic systems, so this is why I am here, to learn from you guys. Any info is extremely useful to me. So, I appreciate your help very much.