Your engine is supplied with a pre-filter and fuel filter with a fine gauze in the lift pump and should be serviced regularly.

If the engineers who designed the engine feel its sufficient why all the mental masturbation ?

EACH tank requires a non return valve at the tank, if you have more than one tank a simple lever valve (handle inline ON, at 90 degrees OFF) system will suffice .

ALL tanks need a sump and drain cock that can be checked once a month to drain any sediment or moisture, alternatively, drain the tank of fuel, use a wet & dry vacuum cleaner to hoover the floor of the tank and refill it.

K.I.S.S.

In my case, my tanks do not have a sump or drain and interior access is limited. It would be nice if they did, but even so, I'd still have an off-engine fuel filtering system!

I'd argue that the engine design engineers intended all along that the engine be run with a separate fuel filtration system. The small on-engine filter is designed as a fail-safe system to protect the injection pump. It was never intended to used as the sole means of fuel filtration. Most over-the-road trucks incorporate a separate off-engine fuel filter because it is easier to maintain and doesn't require bleeding the engine after changing.

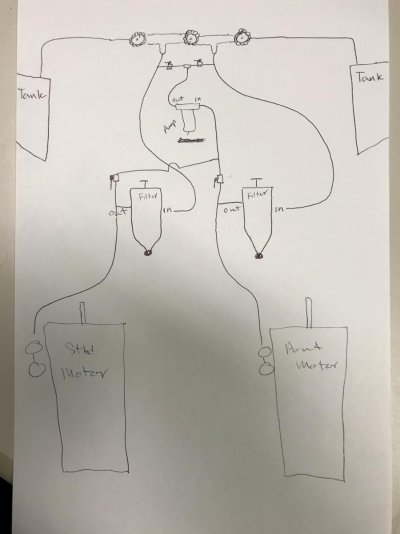

"Why are simple straight forward fuel systems turned into a plumbers nightmare."? The answer is to prevent even worse nightmares at sea. Servicing a clogged on-engine fuel filter at sea is a nightmare that requires shutting down the engine, risking severe burns to change the filter and bleeding the engine before re-start. Not something you want to do while rolling 20-30 degrees mid-ocean in a hot engine room! With a duel off-engine filter system, if during routine engine checks you see an increase in vacuum indicating a fuel restriction from a fouled filter you can turn a valve to switch to the alternate filter while underway, change the fouled filter and switch back without ever shutting down the engine. On MOJO we run on the Gulf Coast filter - the Racor is just a back-up. A filter change costs the price of a roll of Bounty paper towels and filters to sub-micron levels. The on-engine filter remains clean and does not need changing. A well designed off-engine filtering system is not mental masturbation. It's a practical approach to prevent problems, and to also easily solve those that might happen.

In a perfect world where only crystal clean fuel is dispensed at the pump, tanks are drained and cleaned regularly, and the on-engine filter is serviced monthly, you're probably OK relying on that filter alone. But in a world where there's a very real risk of taking on a load of dirty fuel, where fuel can sit in tanks for months or years, and where tanks can't be drained and cleaned frequently, without some form of pre-filtering even a brand new small on-engine filter can/will quickly become restricted, leaving you in extremis!

I'd be surprised if 90+% of all trawlers and sailboats don't have some sort of off-engine fuel filter in addition to the primary on-engine filter(s). Boats that rely on just their engine for propulsion, especially those designed to cross oceans, will have a dual filtration system allowing them to keep running while filters are serviced.