Jeff F

Guru

- Joined

- Nov 5, 2015

- Messages

- 2,437

- Location

- Canada

- Vessel Name

- Escapade

- Vessel Make

- 50` US Navy Utility trawler conversion

Long story, but since many of us have extra time, here goes:

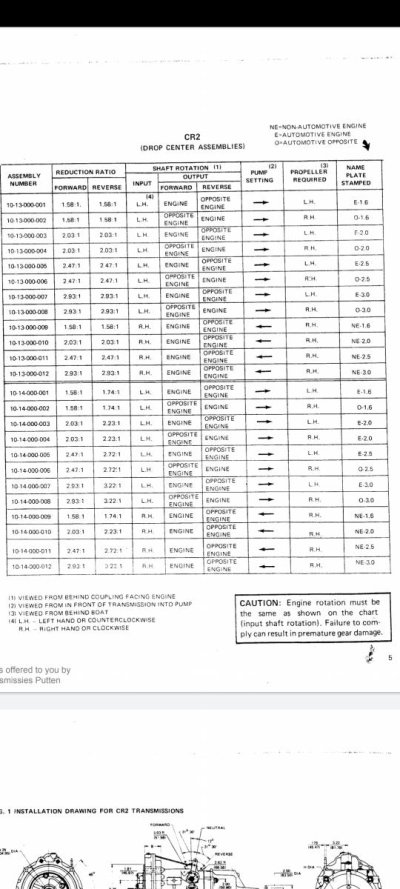

My Mainship 34 M1 is on its original transmission, which is a 72C 2.1 CR.

Since the PO swapped to a Cummins about 2400 hours ago it's been run LH instead of RH. I had seen the direction arrow but hadn't really twigged until I pulled the motor and transmission a couple of years ago. At that time I swapped motors from a 210 to a 250 hp but left the prop and transmission untouched apart from new seals and damper plate. The boat has a 20x24 prop which was about right for the 210 in light ship. I figured the 250 wouldn't mind that and would accommodate cruising trim. Wasn't really looking for more top speed.

Long story short, I think I've killed the reduction gear. I was getting gear noises late last season and there is a noticable fore and aft play at the coupling. No surprise, I guess.

In preparation for this event I acquired a 71C 1.5 locally about a year ago. My plan is to pull the old transmission, swap reduction gears, and swap props. I researched this when I repowered, and decided then that I'd be better off with a 1.5 reduction.

Any advice/concerns? I'll probably replace seals and gaskets as I did last time. I had the reduction gear off last time, and everything I read says they're interchangeable.

I'll introduce the prop question in a different thread.

Thanks!

My Mainship 34 M1 is on its original transmission, which is a 72C 2.1 CR.

Since the PO swapped to a Cummins about 2400 hours ago it's been run LH instead of RH. I had seen the direction arrow but hadn't really twigged until I pulled the motor and transmission a couple of years ago. At that time I swapped motors from a 210 to a 250 hp but left the prop and transmission untouched apart from new seals and damper plate. The boat has a 20x24 prop which was about right for the 210 in light ship. I figured the 250 wouldn't mind that and would accommodate cruising trim. Wasn't really looking for more top speed.

Long story short, I think I've killed the reduction gear. I was getting gear noises late last season and there is a noticable fore and aft play at the coupling. No surprise, I guess.

In preparation for this event I acquired a 71C 1.5 locally about a year ago. My plan is to pull the old transmission, swap reduction gears, and swap props. I researched this when I repowered, and decided then that I'd be better off with a 1.5 reduction.

Any advice/concerns? I'll probably replace seals and gaskets as I did last time. I had the reduction gear off last time, and everything I read says they're interchangeable.

I'll introduce the prop question in a different thread.

Thanks!