HeadedToTexas

Guru

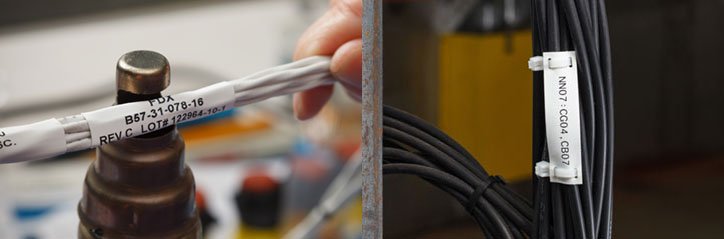

My Engine Room has the same sea of wires and hoses as most. I have reached the limit of my memory and have grown tired of tracing down the same wire over and over to be sure it's the right one.

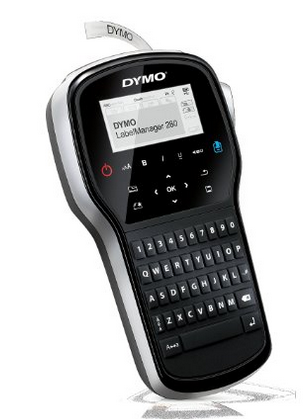

Label printers like this one are neat and inexpensive, but the cost of labels popping off in the heat or vibration or humidity or salt environment and the possibility that they clog a bilge pump and create a disaster makes me believe there is a better answer. What do you guys do?

Label printers like this one are neat and inexpensive, but the cost of labels popping off in the heat or vibration or humidity or salt environment and the possibility that they clog a bilge pump and create a disaster makes me believe there is a better answer. What do you guys do?