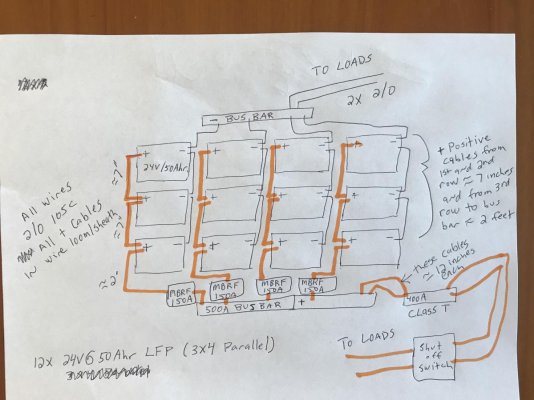

Cables the originate at the battery and are sheathed can have OCP as much as 72" away, closer is always preferred. Wires that are are less than 7" long are exempt from OCP requirements.

The distance requirements, 72" for instance, is not collective. If I'm understanding your question, you are asking if collectively, these wire runs between batteries, are under 72" before OCP, are you compliant. The answer is no because there are 'new sources of power', each battery to which the wire is connected, which isolates the previous runs for OCP purposes.

Technically, if you have wire runs between batteries within a bank that are more than 7", from a positive terminal, they would need OCP, at both ends, which may be impractical unless you use the fuses that mount directly to the terminal. In the real world, wire runs between batteries, within a contiguous bank, typically aren't fused. Batteries that are part of the same bank electrically, but separated physically, a house bank that is connected to a thruster bank for instance, require OCP at both ends of the positive interconnecting cable.

My take on OCP

https://stevedmarineconsulting.com/over-current-protection/

Here's the relevant standard...

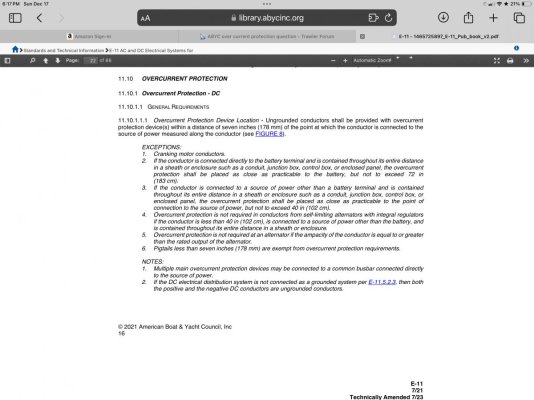

11.10 OVERCURRENT PROTECTION

11.10.1 Overcurrent Protection - DC

11.10.1.1 GENERAL REQUIREMENTS

11.10.1.1.1 Overcurrent Protection Device Location - Ungrounded conductors shall be provided with overcurrent protection device(s) within a distance of seven inches (178 mm) of the point at which the conductor is connected to the source of power measured along the conductor (see FIGURE 8).

EXCEPTIONS:

1. Cranking motor conductors.

2. If the conductor is connected directly to the battery terminal and is contained throughout its entire distance in a sheath or enclosure such as a conduit, junction box, control box, or enclosed panel, the overcurrent protection shall be placed as close as practicable to the battery, but not to exceed 72 in (183 cm).

3. If the conductor is connected to a source of power other than a battery terminal and is contained throughout its entire distance in a sheath or enclosure such as a conduit, junction box, control box, or enclosed panel, the overcurrent protection shall be placed as close as practicable to the point of connection to the source of power, but not to exceed 40 in (102 cm).

4. Overcurrent protection is not required in conductors from self-limiting alternators with integral regulators if the conductor is less than 40 in (102 cm), is connected to a source of power other than the battery, and is contained throughout its entire distance in a sheath or enclosure.

5. Overcurrent protection is not required at an alternator if the ampacity of the conductor is equal to or greater than the rated output of the alternator.

6. Pigtails less than seven inches (178 mm) are exempt from overcurrent protection requirements.

NOTES:

1. Multiple main overcurrent protection devices may be connected to a common busbar connected directly to the source of power.

2. If the DC electrical distribution system is not connected as a grounded system per E-11.5.2.3, then both the positive and the negative DC conductors are ungrounded conductors.

And...

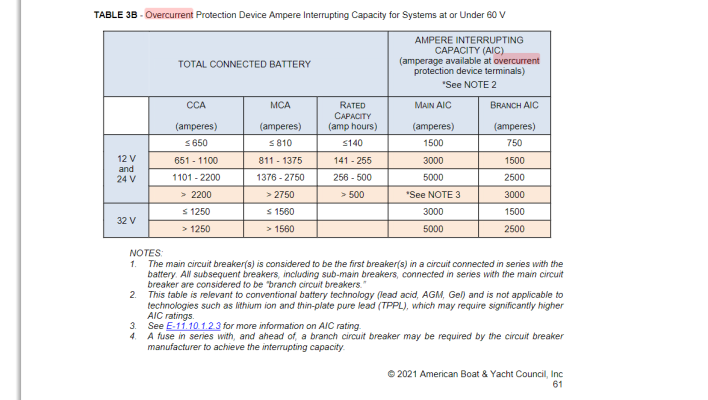

11.10.1.2 MAIN BATTERY OVERCURRENT PROTECTION

11.10.1.2.1 Overcurrent protection devices when installed as the main battery overcurrent protection device shall meet the requirements of E-11.10.1.6 or E-11.10.1.7.

11.10.1.2.2 For batteries or battery banks with a rating of 2200 CCA or 500 amp hours or less, battery overcurrent protection shall have a minimum ampere interrupting capacity (AIC) rating according to TABLE 3B.

11.10.1.2.3 For batteries or battery banks with a CCA rating greater than 2200 CCA or 500 amp hours, battery overcurrent protection shall have a minimum ampere interrupting capacity (AIC) rating as follows:

11.10.1.2.3.1 at least as great as the battery manufacturer’s short circuit rating, or

11.10.1.2.3.2 20 kA at 125 VDC or higher, if a battery manufacturer’s short circuit rating exceeds 10 kA.

NOTE: For batteries in series/parallel configurations the short circuit current of the battery bank is calculated by adding the short circuit current values of the batteries connected in parallel, and the short circuit rating of the batteries connected in series is not added for this calculation (e.g., six 6 VDC batteries are connected in series/parallel to create 12 VDC battery bank; if short circuit rating of a single battery equals 2400 A, the total calculated short circuit rating of the battery bank equals 7200 A).

11.10.1.2.4 Fuses, when used as main battery overcurrent protection, shall meet the ampere interrupting capacity (AIC) rating as stated in TABLE 3B.

EXCEPTION: Fuses less than or equal to 30 amps in 12 V systems, 15 amps in 24 V systems, and 12 amps in 32 V systems.