paulga

Guru

- Joined

- May 28, 2018

- Messages

- 976

- Location

- United States

- Vessel Name

- DD

- Vessel Make

- Marine Trader Sundeck 40'

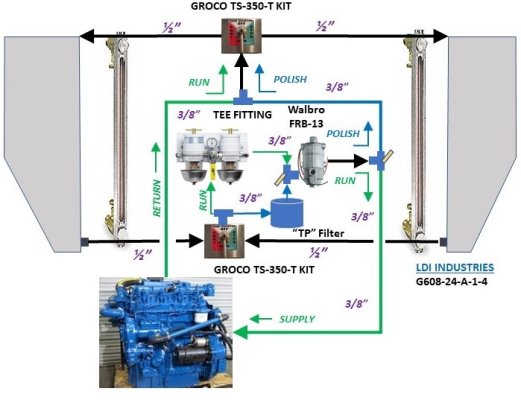

The fuel tanks one on each side of the boat are connected via the thick braided blue hose. The control valve is open, so the fuel should be drawn from both tanks in which the diesel should always have the same level. But the portside fuel gauge shows "17" while the starboard side is at the "21" mark. What could lead to the tilt?