You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nova cool fridge normal or not?

- Thread starter mncruiser

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,330

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

The humid air gets into the fridge when the door is open, then freezes inside. As to the running time, add a vent both high and low to allow heat get out of cabinet. I added a 50 mAmp fan that was hooked onto the control board and ran whenever the compressor ran. Amazing difference on how the refer performed after modifications.

mncruiser

Senior Member

The humid air gets into the fridge when the door is open, then freezes inside. As to the running time, add a vent both high and low to allow heat get out of cabinet. I added a 50 mAmp fan that was hooked onto the control board and ran whenever the compressor ran. Amazing difference on how the refer performed after modifications.

Hey Dave!

So you’d say the ice build up is not normal and not desirable?

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,330

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

No the ice buildup makes it less efficient. Have to do a manual defrost when it gets too thick. The running too much has some to do with the ice buildup but more probably with the cabinet lack of ventilation.

As Comodave says, ventilation (to allow the compressor unit to get rid of its heat) is always key. Along the same lines, you can wire a fan to two specific tangs on the electronic module, and it will come on whenever the compressor runs (along with the one that is probably already on there).

I also agree that if you open the refrigerator a lot in a humid climate, you can get more frost.

Here's one I hadn't thought of until I experienced it: I had always used covered containers to make ice (trays or individual molds). At one point I didn't have those and used open trays instead. I'm in a dry place but still the freezer (plate) seemed to frost up noticeably faster just from the open moisture source.

Another thought, if you like tweaking: I would guess your Nova Kook uses one of the Danfoss/Secop compressors. Such as the BD35 (usually in units smaller than around 130 liters) or larger BD50.

These units usually use a resistor on the control module to control the speed of the compressor. For example, my BD35 (in one of the larger units it's put in) came with a resistor that results in the compressor running at 3,000 rpm. The range they recommend is from 2,000 rpm to 3,500 rpm. You can control that by changing the resistor (or they make little "dials" where you can select).

They say a good goal is for the compressor to have a 50% duty cycle. Or to put it another way, the lower rpm you can run it the more efficient, so basically run as low as you can without exceeding 50% duty cycle.

Another factor might be if you use it "atypically" such as let's say you leave it off all week, then come to the boat Friday night and fill it with warm food. Meaning you want it to cool down a large quantity of stuff as compared to one that just runs every day and maintains. Faster rpm would do that better. Probably ditto if you have it open a fair bit.

So as an example, as mentioned above, my refrigerator/freezer came with the resistor value that runs the compressor at 3,000 rpm. I wanted to see if I could do better. The lowest speed, 2,000 rpm, is achieved with no resistor. So I made up a little harness with a switch. Switched one way, I get 2,000 rpm (no resistor); switched the other way, I'm back to 3,000 rpm with the resistor they supplied.

As it turned out, I could easily run it at 2,000 rpm and stay at or below a 50% duty cycle, with the temps staying just fine. Side bonus, it was quieter when it did run, and used less power in a given day.

That was fine until I got into some extremely hot weather. Then the temps were rising a bit as was the duty cycle. I flipped the switch back to the 3,000 rpm setting and all was good again. Once ambient temps cool back down a bit, I can flip it back to 2,000 rpm.

Since you may be "working" the unit a bit more, then if you have it running at a lower rpm (you can check the resistor), you could try upping it.

(If you are interested I can come back with the various resistor values.)

Edited to add:

I just learned by reading the Danfoss/Secop literature, poking around online, making a couple of calls, and then experimenting. But I'm no expert. Also, things might be different on someone else's refrigerator (for example if you already have some sort of adaptive energy optimizer that tweaks the rpms on it's own). My Vitrifrigo just has a "plain" BD35.

I also agree that if you open the refrigerator a lot in a humid climate, you can get more frost.

Here's one I hadn't thought of until I experienced it: I had always used covered containers to make ice (trays or individual molds). At one point I didn't have those and used open trays instead. I'm in a dry place but still the freezer (plate) seemed to frost up noticeably faster just from the open moisture source.

Another thought, if you like tweaking: I would guess your Nova Kook uses one of the Danfoss/Secop compressors. Such as the BD35 (usually in units smaller than around 130 liters) or larger BD50.

These units usually use a resistor on the control module to control the speed of the compressor. For example, my BD35 (in one of the larger units it's put in) came with a resistor that results in the compressor running at 3,000 rpm. The range they recommend is from 2,000 rpm to 3,500 rpm. You can control that by changing the resistor (or they make little "dials" where you can select).

They say a good goal is for the compressor to have a 50% duty cycle. Or to put it another way, the lower rpm you can run it the more efficient, so basically run as low as you can without exceeding 50% duty cycle.

Another factor might be if you use it "atypically" such as let's say you leave it off all week, then come to the boat Friday night and fill it with warm food. Meaning you want it to cool down a large quantity of stuff as compared to one that just runs every day and maintains. Faster rpm would do that better. Probably ditto if you have it open a fair bit.

So as an example, as mentioned above, my refrigerator/freezer came with the resistor value that runs the compressor at 3,000 rpm. I wanted to see if I could do better. The lowest speed, 2,000 rpm, is achieved with no resistor. So I made up a little harness with a switch. Switched one way, I get 2,000 rpm (no resistor); switched the other way, I'm back to 3,000 rpm with the resistor they supplied.

As it turned out, I could easily run it at 2,000 rpm and stay at or below a 50% duty cycle, with the temps staying just fine. Side bonus, it was quieter when it did run, and used less power in a given day.

That was fine until I got into some extremely hot weather. Then the temps were rising a bit as was the duty cycle. I flipped the switch back to the 3,000 rpm setting and all was good again. Once ambient temps cool back down a bit, I can flip it back to 2,000 rpm.

Since you may be "working" the unit a bit more, then if you have it running at a lower rpm (you can check the resistor), you could try upping it.

(If you are interested I can come back with the various resistor values.)

Edited to add:

I just learned by reading the Danfoss/Secop literature, poking around online, making a couple of calls, and then experimenting. But I'm no expert. Also, things might be different on someone else's refrigerator (for example if you already have some sort of adaptive energy optimizer that tweaks the rpms on it's own). My Vitrifrigo just has a "plain" BD35.

Last edited:

High Wire

Guru

The frost is pretty normal. Boat and RV fridges do not have auto defrost capability like a home fridge. You just have to manually defrost every few months to keep the efficiency up. Careful use of a heat gun makes it a half hour job. Absolutely no screwdriver chipping!!!

High Wire

Guru

How do you know what rpm the compressor is running?Another thought, if you like tweaking: I would guess your Nova Kook uses one of the Danfoss/Secop compressors. Such as the BD35 (usually in units smaller than around 130 liters) or larger BD50.

These units usually use a resistor on the control module to control the speed of the compressor. For example, my BD35 (in one of the larger units it's put in) came with a resistor that results in the compressor running at 3,000 rpm. The range they recommend is from 2,000 rpm to 3,500 rpm. You can control that by changing the resistor (or they make little "dials" where you can select).

They say a good goal is for the compressor to have a 50% duty cycle. Or to put it another way, the lower rpm you can run it the more efficient, so basically run as low as you can without exceeding 50% duty cycle.

So as an example, as mentioned above, my refrigerator/freezer came with the resistor value that runs the compressor at 3,000 rpm. I wanted to see if I could do better. The lowest speed, 2,000 rpm, is achieved with no resistor. So I made up a little harness with a switch. Switched one way, I get 2,000 rpm (no resistor); switched the other way, I'm back to 3,000 rpm with the resistor they supplied.

As it turned out, I could easily run it at 2,000 rpm and stay at or below a 50% duty cycle, with the temps staying just fine. Side bonus, it was quieter when it did run, and used less power in a given day.

That was fine until I got into some extremely hot weather. Then the temps were rising a bit as was the duty cycle. I flipped the switch back to the 3,000 rpm setting and all was good again. Once ambient temps cool back down a bit, I can flip it back to 2,000 rpm.

Since you may be "working" the unit a bit more, then if you have it running at a lower rpm (you can check the resistor), you could try upping it.

(If you are interested I can come back with the various resistor values.)

Last edited:

backinblue

Guru

- Joined

- Jan 29, 2019

- Messages

- 3,937

- Location

- USA

- Vessel Name

- Blue Moon

- Vessel Make

- Mainship Pilot 355

Ice buildup is not good. I just defrosted mine. No heat gun or chipping tools, just left it off on a hot day for a few hours with the door open. A year or 2 ago I bought this because I wasn't sure how cold to set the thermostat:

https://www.amazon.com/gp/product/B005KDEFNK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Once defrosted and set to the correct temp, the thermometer is a good indicator of when I need a defrost because even when plugged in to AC, the temp will begin to rise as more ice accumulates.

https://www.amazon.com/gp/product/B005KDEFNK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Once defrosted and set to the correct temp, the thermometer is a good indicator of when I need a defrost because even when plugged in to AC, the temp will begin to rise as more ice accumulates.

How do you know what rpm the compressor is running?

How I found out what resistance is what speed is by looking in Danfoss/Secop literature (plus a phone call to them to confirm my hunch about lowest rpm that can properly do the job being a good idea).

Then on my specific refrigerator (Vitrifrigo), they put a colored dot on the different resistors so it's a simple glance.

(Also you could use any resistance value in between those - they are not specific magic).

For some data, here is what Vitrifrigo chooses as the stock resistor for the various refrigerator models (their numbers correspond to liters of capacity) (these are on a little board that then pushes onto the tangs on the Danfoss/Secop module; but when I made my harness I just used regular .25" quick connects on the tangs and have the resistor off to the side along with my switch):

Part # R101023.1

Resistor card,1523 Ohms, Yellow dot (3500rpm) (stock on C55BT/C110BT/C65 models)

Part # R101022.1

Resistor card, 692 Ohms, Black dot (3000rpm) (stock on C30BT/C130/DP2600)

Part # R101021.1

Resistor card, 277 Ohms, Red dot (2500rpm) (stock on C51/C60/C62/C85/C115)

*****************

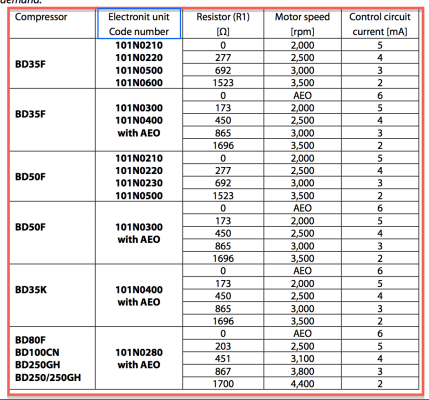

Here is similar data right from Danfoss/Secop's BD compressor literature. The number I outlined with a blue square can be found right on the front (connections side) of the electronic module. I happen to have the 101N0500 (circa 2014).

Attachments

Frosty,

Excellent info... you must be a refrigeration guy.

FWIW, my last boat had a NovaCool (vintage 2005) and it did pretty good for the most part. Minimal defrosting required, but it did need it occasionally.

The freezer was the weak part, and would not keep ice cream really frozen, but was adequate for most stuff. However, after ~15 years was probably ready for a replacement.

Also, customer service was great.

Excellent info... you must be a refrigeration guy.

FWIW, my last boat had a NovaCool (vintage 2005) and it did pretty good for the most part. Minimal defrosting required, but it did need it occasionally.

The freezer was the weak part, and would not keep ice cream really frozen, but was adequate for most stuff. However, after ~15 years was probably ready for a replacement.

Also, customer service was great.

While we are on the subject of tweaking the BD35 or BD50 Danfoss/Secop compressors (I hope this is not too off-topic), here are a couple of additional easy tweaks.

So this is what the electrical connection side of the control module looks like (not sure how to put photos inline, sorry, so it's at the bottom).

There will already be a number of wires "quick connected" onto these tangs.

1) The upper two, if you have them, are for AC power if your refrigerator also runs on AC.

2) In the next section down, there will be the incoming DC power wires on the + and - terminals.

3) Wires on A and the upper C will power the light inside the refrigerator

4) Wires on the lower C and T will power the thermostat.

5) T will have any resistor inline with the thermostat wire.

A couple of options:

6) Some refrigerators already have this (mine did not), but if you wire an LED light across terminals D and +, it will give you error codes if there is a problem (flashes). There are diagnostic lists online.

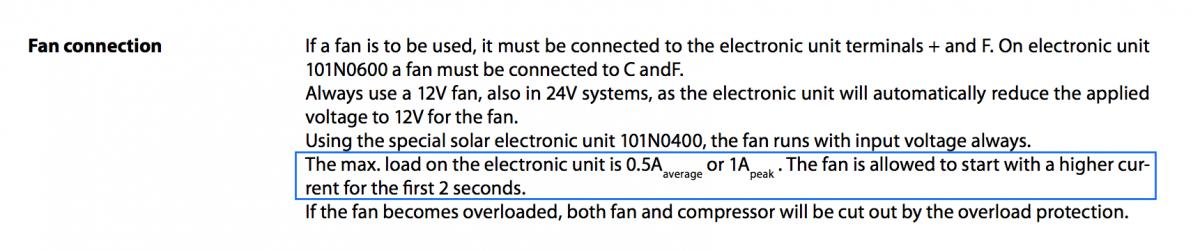

7) If you wire a fan (this is separate from any stock fan) across terminals F and +, then that fan will come on whenever the compressor runs. It should be a 12 volt fan (even on 24 volt refrigerator) and draw less than .5 amps

My installation is well ventilated, so I have not added an extra fan; but I did replace the stock "built in" compressor fan (which I assume Vitrifrigo chose). It was a very run of the mill muffin type fan with cheapish bearings and was quite noisy.

There are a zillion choices but I used a Noctua NF-A 12 x 25. I am by no means a fan expert, so I contacted Noctua because I was a bit confused which one to choose. Turns out the "A" model is good for when you have static pressure. The stock fan is right up against a "radiator" part of the compressor so the "A" is good for that. If a second fan were mounted in "free air" just to move air around then they would have recommended the NF-F 12 x 25.

I was super impressed by the Noctua fans (I ended up with one of each). Heavy, high quality, rubber trim pieces, and even its own little resistor that you can put on or not to control the fan speed (tweaking the tweaks :lol .

.

On mine that "built in" fan was held on by four screws at the corners. They were pretty hard to get to, so I put the new one on with four zip ties. Seems fine.

A tip I picked up from a few marine refrigeration sites is to try to make sure you don't get a "circle" of air. i.e. hot air coming off the compressor can be sucked in by the fan again. I used some foam sheets in combination with some sheet aluminum to give the fan a sort of "photographer's hood" so that it can't re-suck the hot air but can only take in fresh air. There is a fair bit of variation in how the compressors are situated though.

**************

As I mentioned in the post above, don't take this as gospel. I just learned by reading the Danfoss/Secop literature, poking around online, making a couple of calls, and then experimenting. But I'm no expert. Also, things might be different on someone else's refrigerator (for example if you already have some sort of adaptive energy optimizer that tweaks the rpms on it's own). My Vitrifrigo just has a "plain" BD35.

So this is what the electrical connection side of the control module looks like (not sure how to put photos inline, sorry, so it's at the bottom).

There will already be a number of wires "quick connected" onto these tangs.

1) The upper two, if you have them, are for AC power if your refrigerator also runs on AC.

2) In the next section down, there will be the incoming DC power wires on the + and - terminals.

3) Wires on A and the upper C will power the light inside the refrigerator

4) Wires on the lower C and T will power the thermostat.

5) T will have any resistor inline with the thermostat wire.

A couple of options:

6) Some refrigerators already have this (mine did not), but if you wire an LED light across terminals D and +, it will give you error codes if there is a problem (flashes). There are diagnostic lists online.

7) If you wire a fan (this is separate from any stock fan) across terminals F and +, then that fan will come on whenever the compressor runs. It should be a 12 volt fan (even on 24 volt refrigerator) and draw less than .5 amps

My installation is well ventilated, so I have not added an extra fan; but I did replace the stock "built in" compressor fan (which I assume Vitrifrigo chose). It was a very run of the mill muffin type fan with cheapish bearings and was quite noisy.

There are a zillion choices but I used a Noctua NF-A 12 x 25. I am by no means a fan expert, so I contacted Noctua because I was a bit confused which one to choose. Turns out the "A" model is good for when you have static pressure. The stock fan is right up against a "radiator" part of the compressor so the "A" is good for that. If a second fan were mounted in "free air" just to move air around then they would have recommended the NF-F 12 x 25.

I was super impressed by the Noctua fans (I ended up with one of each). Heavy, high quality, rubber trim pieces, and even its own little resistor that you can put on or not to control the fan speed (tweaking the tweaks :lol

On mine that "built in" fan was held on by four screws at the corners. They were pretty hard to get to, so I put the new one on with four zip ties. Seems fine.

A tip I picked up from a few marine refrigeration sites is to try to make sure you don't get a "circle" of air. i.e. hot air coming off the compressor can be sucked in by the fan again. I used some foam sheets in combination with some sheet aluminum to give the fan a sort of "photographer's hood" so that it can't re-suck the hot air but can only take in fresh air. There is a fair bit of variation in how the compressors are situated though.

**************

As I mentioned in the post above, don't take this as gospel. I just learned by reading the Danfoss/Secop literature, poking around online, making a couple of calls, and then experimenting. But I'm no expert. Also, things might be different on someone else's refrigerator (for example if you already have some sort of adaptive energy optimizer that tweaks the rpms on it's own). My Vitrifrigo just has a "plain" BD35.

Attachments

In case anyone has not dozed off yet  , something new I'm trying:

, something new I'm trying:

Before I installed my Vitrifrigo, I was using one of the "travel box" style refrigerators. It's basically a cooler shaped box, but still uses the BD35 compressor. If you've ever used one you've seen this, but they have a digital thermostat on the outside of the box. So you can see the inside temperature, see what you have set, and also change the temp setting in increments. Nice!

I had gotten totally used to that when I put in my "real" refrigerator. It's a great unit, but suddenly I was back to the old mechanical thermostat (just a dial with numbers like 1-6), AND it's buried in the back of the refrigerator. I then realized how spoiled I had become with the other type.

There are some nice digital thermostats you can add on. Stainless Lobster made a really slick one (and it's now back in production but close to $300). Isotherm also makes on if you have the newest BD module (mine is one generation too old). Also not cheap.

Then I read a post on a boater's blog about how they were having some sort of glitch in an older Nova Kool, and to fix it they picked up an "Inkbird" digital thermostat from Amazon. $15. They hooked it up and away they went. Hmmm....

Well a buddy and I both ordered one and although I have not gotten to mine yet, he installed his (same refrigerator/compressor as I have as it happens) and said it's super slick. Not only can you see and manipulate the temp outside the refrigerator (in ºF or ºC), but you can set the hysteresis if you want to. It's on my to-do list.

(You wire it in to the thermostat quick connects on the control module, and then you also have to feed their thermostat "bulb" into the refrigerator in lieu of the mechanical one.)

Here is a link to the one I'm speaking of:

https://www.amazon.com/gp/product/B019I3YCFS

They make a few different models (some are 120v, etc.) that look similar.

BTW, I have noticed that some of Vitrifrigo's top of the line units are now incorporating digital thermostats into the door (so far it's the larger/stainless/fancier ones).

MN Cruiser: I hope you are not thinking "GEEZ, I just asked about a little frost build up!" I wouldn't totally blame you as I may have gotten a bit carried away I just think it's neat that you can tweak the compressors and they even tell you how!

I just think it's neat that you can tweak the compressors and they even tell you how!

Before I installed my Vitrifrigo, I was using one of the "travel box" style refrigerators. It's basically a cooler shaped box, but still uses the BD35 compressor. If you've ever used one you've seen this, but they have a digital thermostat on the outside of the box. So you can see the inside temperature, see what you have set, and also change the temp setting in increments. Nice!

I had gotten totally used to that when I put in my "real" refrigerator. It's a great unit, but suddenly I was back to the old mechanical thermostat (just a dial with numbers like 1-6), AND it's buried in the back of the refrigerator. I then realized how spoiled I had become with the other type.

There are some nice digital thermostats you can add on. Stainless Lobster made a really slick one (and it's now back in production but close to $300). Isotherm also makes on if you have the newest BD module (mine is one generation too old). Also not cheap.

Then I read a post on a boater's blog about how they were having some sort of glitch in an older Nova Kool, and to fix it they picked up an "Inkbird" digital thermostat from Amazon. $15. They hooked it up and away they went. Hmmm....

Well a buddy and I both ordered one and although I have not gotten to mine yet, he installed his (same refrigerator/compressor as I have as it happens) and said it's super slick. Not only can you see and manipulate the temp outside the refrigerator (in ºF or ºC), but you can set the hysteresis if you want to. It's on my to-do list.

(You wire it in to the thermostat quick connects on the control module, and then you also have to feed their thermostat "bulb" into the refrigerator in lieu of the mechanical one.)

Here is a link to the one I'm speaking of:

https://www.amazon.com/gp/product/B019I3YCFS

They make a few different models (some are 120v, etc.) that look similar.

BTW, I have noticed that some of Vitrifrigo's top of the line units are now incorporating digital thermostats into the door (so far it's the larger/stainless/fancier ones).

MN Cruiser: I hope you are not thinking "GEEZ, I just asked about a little frost build up!" I wouldn't totally blame you as I may have gotten a bit carried away

I just think it's neat that you can tweak the compressors and they even tell you how!

I just think it's neat that you can tweak the compressors and they even tell you how!High Wire

Guru

COOL Thanks!How I found out what resistance is what speed is by looking in Danfoss/Secop literature (plus a phone call to them to confirm my hunch about lowest rpm that can properly do the job being a good idea).

Then on my specific refrigerator (Vitrifrigo), they put a colored dot on the different resistors so it's a simple glance.

(Also you could use any resistance value in between those - they are not specific magic).

For some data, here is what Vitrifrigo chooses as the stock resistor for the various refrigerator models (their numbers correspond to liters of capacity) (these are on a little board that then pushes onto the tangs on the Danfoss/Secop module; but when I made my harness I just used regular .25" quick connects on the tangs and have the resistor off to the side along with my switch):

Part # R101023.1

Resistor card,1523 Ohms, Yellow dot (3500rpm) (stock on C55BT/C110BT/C65 models)

Part # R101022.1

Resistor card, 692 Ohms, Black dot (3000rpm) (stock on C30BT/C130/DP2600)

Part # R101021.1

Resistor card, 277 Ohms, Red dot (2500rpm) (stock on C51/C60/C62/C85/C115)

*****************

Here is similar data right from Danfoss/Secop's BD compressor literature. The number I outlined with a blue square can be found right on the front (connections side) of the electronic module. I happen to have the 101N0500 (circa 2014).

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

On my American Tug, I have the Nova Kool 8000DC.

There has been a lot of discussion on how to improve the operation.

I added an additional foam insulation board on the top and sides. I am not sure there was any benefit. I added the Stainless Lobster with its force defrost cycle.

You can also select the box temp too. On the AT there is away to modify the shelf between the fridge compartment and the shelf the microwave sits on add some ducting to vent out the back. I have yet to install an additional fan to the compressor area nor a fan to "encourage" the removal of the heat buildup, behind the box.

I did put in a vent at the base to draw more air into the area near the compressor.

For now, it is all natural convection.... more air into the compressor area and heat escaping up from the fridge compartment out, behind the fridge/microwave compartments.

After all these modifications, I may get an additional week before I have to do a manual defrost.

To review:

1/2 inch foam insulation board.

Stainless lobster

Additional venting of the space behind the fridge unit.

Results?

Yea right. All bets are off if you open the fridge door or freezer door.

It is the HUMIDITY BUILD UP inside the box that forms the ice of the coils.

Until someone conquers the humidity build up inside the box, we just must get used to manually defrosting the fridge and freezer.

There has been a lot of discussion on how to improve the operation.

I added an additional foam insulation board on the top and sides. I am not sure there was any benefit. I added the Stainless Lobster with its force defrost cycle.

You can also select the box temp too. On the AT there is away to modify the shelf between the fridge compartment and the shelf the microwave sits on add some ducting to vent out the back. I have yet to install an additional fan to the compressor area nor a fan to "encourage" the removal of the heat buildup, behind the box.

I did put in a vent at the base to draw more air into the area near the compressor.

For now, it is all natural convection.... more air into the compressor area and heat escaping up from the fridge compartment out, behind the fridge/microwave compartments.

After all these modifications, I may get an additional week before I have to do a manual defrost.

To review:

1/2 inch foam insulation board.

Stainless lobster

Additional venting of the space behind the fridge unit.

Results?

Yea right. All bets are off if you open the fridge door or freezer door.

It is the HUMIDITY BUILD UP inside the box that forms the ice of the coils.

Until someone conquers the humidity build up inside the box, we just must get used to manually defrosting the fridge and freezer.

backinblue

Guru

- Joined

- Jan 29, 2019

- Messages

- 3,937

- Location

- USA

- Vessel Name

- Blue Moon

- Vessel Make

- Mainship Pilot 355

On my American Tug, I have the Nova Kool 8000DC.

There has been a lot of discussion on how to improve the operation.

I added an additional foam insulation board on the top and sides. I am not sure there was any benefit. I added the Stainless Lobster with its force defrost cycle.

You can also select the box temp too. On the AT there is away to modify the shelf between the fridge compartment and the shelf the microwave sits on add some ducting to vent out the back. I have yet to install an additional fan to the compressor area nor a fan to "encourage" the removal of the heat buildup, behind the box.

I did put in a vent at the base to draw more air into the area near the compressor.

For now, it is all natural convection.... more air into the compressor area and heat escaping up from the fridge compartment out, behind the fridge/microwave compartments.

After all these modifications, I may get an additional week before I have to do a manual defrost.

To review:

1/2 inch foam insulation board.

Stainless lobster

Additional venting of the space behind the fridge unit.

Results?

Yea right. All bets are off if you open the fridge door or freezer door.

It is the HUMIDITY BUILD UP inside the box that forms the ice of the coils.

Until someone conquers the humidity build up inside the box, we just must get used to manually defrosting the fridge and freezer.

Stainless lobster??

mncruiser

Senior Member

Not at all! Thanks all for the information. I think I surely need to defrost, but also need to add a vent. The challenge there is the stacks of cabinets around it.

I may investigate adding a vent through one of the cabinets to the side.

Temp monitors are probably in my future, we are either freezing or thawing. And both of us are adjusting the dial without telling each other, lol, that isn’t helping. And the littles open the fridge a zillion times a day!

I may investigate adding a vent through one of the cabinets to the side.

Temp monitors are probably in my future, we are either freezing or thawing. And both of us are adjusting the dial without telling each other, lol, that isn’t helping. And the littles open the fridge a zillion times a day!

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

One other thing, the first thing is to change out the door seals on both upper and lower boxes in an attempt to keep the humidity out and the cold in.

Both boxes are small so it doesn't much humidity to start the ice build up.

I still, barely, remember the iceman cometh to put a block of ice in the ice box. Then the improvement of an actual refrigerator and finally self defrosting.

The Stainless Lobster's defrost cycle and length of defrosting is an 'attempt' to reduce the ice build up.

They are based upon TIME and both can be set by the user.

Ah one point I did not mention. Some recommend removing upper box drip pan, to get greater air movement across the cooling coils, others say, leave it in place.

Normally, I leave the drip pan out except when defrosting. Gotta catch the water, from defrosting, somewhere so why not in the drip pan.

When I defrost, I use a hair drier, not a heat gun.

Per shutting the fridge down if you are gone for a week or more, assuming you have a way to charge the batteries (yea solar panels and/or shore power), I see no reason to shut down the fridge.

I have left mine running when off the boat for 2 month. No shore power, just 3 solar panels.

Everything was fine inside the box and freezer. Why you may ask? The solar panels kept the batteries charged and there wasn't anyone on board to constantly opening and closing the fridge and freezer doors.

No matter how many modifications and improvements we make (putting more perfume on the pig), we still have a Nova Kool.

If I were to voyage for a month or more and failing to remember there are grocery stores along the way, I would investigate a separate 12vt/120vt box type freezer to put in the cockpit. Believe it or not, putting a cover over the box will actually improve the efficiency, I am told.

Anything necessary to keep the beer cold and the ice cream solid. I have discovered, a pint of ice cream will remain solid if stored in the ice cube compartment.

Both boxes are small so it doesn't much humidity to start the ice build up.

I still, barely, remember the iceman cometh to put a block of ice in the ice box. Then the improvement of an actual refrigerator and finally self defrosting.

The Stainless Lobster's defrost cycle and length of defrosting is an 'attempt' to reduce the ice build up.

They are based upon TIME and both can be set by the user.

Ah one point I did not mention. Some recommend removing upper box drip pan, to get greater air movement across the cooling coils, others say, leave it in place.

Normally, I leave the drip pan out except when defrosting. Gotta catch the water, from defrosting, somewhere so why not in the drip pan.

When I defrost, I use a hair drier, not a heat gun.

Per shutting the fridge down if you are gone for a week or more, assuming you have a way to charge the batteries (yea solar panels and/or shore power), I see no reason to shut down the fridge.

I have left mine running when off the boat for 2 month. No shore power, just 3 solar panels.

Everything was fine inside the box and freezer. Why you may ask? The solar panels kept the batteries charged and there wasn't anyone on board to constantly opening and closing the fridge and freezer doors.

No matter how many modifications and improvements we make (putting more perfume on the pig), we still have a Nova Kool.

If I were to voyage for a month or more and failing to remember there are grocery stores along the way, I would investigate a separate 12vt/120vt box type freezer to put in the cockpit. Believe it or not, putting a cover over the box will actually improve the efficiency, I am told.

Anything necessary to keep the beer cold and the ice cream solid. I have discovered, a pint of ice cream will remain solid if stored in the ice cube compartment.

Last edited:

rslifkin

Guru

- Joined

- Aug 20, 2019

- Messages

- 7,607

- Location

- USA

- Vessel Name

- Hour Glass

- Vessel Make

- Chris Craft 381 Catalina

And the littles open the fridge a zillion times a day!

That part has to change. No boat fridge handles being opened a ton of times very well. They frost up, and in hot weather, they'll have trouble keeping up if you use it like a drink cooler. Everyone on board has to be trained to open the fridge as little as possible, and when you do open it, be as quick as possible.

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

That part has to change. No boat fridge handles being opened a ton of times very well. They frost up, and in hot weather, they'll have trouble keeping up if you use it like a drink cooler. Everyone on board has to be trained to open the fridge as little as possible, and when you do open it, be as quick as possible.

Duct tape their arms to the sides of their sweet tender bodies.

rslifkin

Guru

- Joined

- Aug 20, 2019

- Messages

- 7,607

- Location

- USA

- Vessel Name

- Hour Glass

- Vessel Make

- Chris Craft 381 Catalina

Duct tape their arms to the sides of their sweet tender bodies.

When I was a kid on the boat, I'm pretty sure we weren't allowed to touch or open the fridge until we were old enough to understand it. Before that, an adult had to retrieve anything we needed.

tpbrady

Guru

We have been using the Fridge Optimizer for the last couple of years and this year I added a vent fan in the back tied to the compressor. After two months, we have not had to defrost the RFU-9000. The Fridge Optimizer takes care of that, but some of the water from the defrost cycle will drip onto the contents. That isn't a problem.

Tom

Tom

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

I replaced the door seals on my nova kool (same exact fridge as the op) a couple of months ago. Made a HUGE difference in frost buildup.

With all the steps I have taken, I defrost about once every 4-6 weeks. It all depends on the temp inside the box

I replaced the door seals on my nova kool (same exact fridge as the op) a couple of months ago. Made a HUGE difference in frost buildup.

That's a good point. OP, have you done the seal test where you close something like a thin piece of paper in the door and then with the door closed try to pull it out? It should basically be "stuck" between the seals (to a point; obviously you could always manage to pull it out with enough force).

Dougcole

Guru

That's a good point. OP, have you done the seal test where you close something like a thin piece of paper in the door and then with the door closed try to pull it out? It should basically be "stuck" between the seals (to a point; obviously you could always manage to pull it out with enough force).

I tried this test prior to replacing my seals, and they seemed to pass. But I was having to defrost every two weeks, and the seals are not expensive, so I decided to replace them anyway. I can easily go 60 days now without a defrost.

I'm guessing the fridge is more efficient as well.

Start with the little things.

OldDan1943

Guru

- Joined

- Oct 2, 2017

- Messages

- 10,599

- Location

- USA

- Vessel Name

- Kinja

- Vessel Make

- American Tug 34 #116 2008

IMO, the only way to control or eliminate the ice build up is to install a dehumidifier inside the box or, after defrosting, never open the doors. LOL

We have been spoiled with frost free, automatic defrost 'real' refrigerators.

I can think of at least 5 modifications that can be made to the NorKool fridge to improve the efficiency but, it is like putting perfume on a pig. It may smell better but it still a pig.

We have been spoiled with frost free, automatic defrost 'real' refrigerators.

I can think of at least 5 modifications that can be made to the NorKool fridge to improve the efficiency but, it is like putting perfume on a pig. It may smell better but it still a pig.

Last edited:

Stout

Senior Member

Latest owner of Stainless Lobster fridge optimizer

Here is the site for the latest owner of the Stainless Lobster Fridge Optimizer:

https://www.pikavo.com/pikavo/product/pikavo-products/stainless-lobster-digital-fridge-controller

Stainless lobster??

Here is the site for the latest owner of the Stainless Lobster Fridge Optimizer:

https://www.pikavo.com/pikavo/product/pikavo-products/stainless-lobster-digital-fridge-controller

Carriage Guy

Veteran Member

"As Comodave says, ventilation (to allow the compressor unit to get rid of its heat) is always key. Along the same lines, you can wire a fan to two specific tangs on the electronic module, and it will come on whenever the compressor runs (along with the one that is probably already on there)."

++++++++++++++++++++++++++++++++++++

I called the Nova Kool factory last fall when installing our new double door unit. The tech I talked with about installing an aux fan warned me not to exceed .3A total load on their fan pin. Their compressor fan consumes .13A itself leaving only .17A available for a customer supplied fan to remove heat from the coils in tight installations.

We ended up using the control module fan pin to drive a relay to energize both the Nova Kool compressor fan and our own external cooling fan. Pro tip if you go this way: the fan pin (at least on the Nova Kool control module) is active low so the other end of the relay coil needs to be tied to 12V to drive the relay when the compressor turns on. Nova Kool offers their own version of a supplemental relay to drive an external fan if you are not comfortable doing your own "hack".

Regarding resistors to control compressor speeds, our new Nova Kool unit had some early teething pains due to a bad crimp in the stab-on connector of the factory supplied resistor. If the circuit containing that resistor doesn't make continuity, the compressor stops and the fridge/freezer begins to warm. After working with the factory over the phone to troubleshoot our problem and learning more about the variable compressor speeds, we also went with a switch to alternate between several resistor/speed values and plan to use it on a seasonal basis.

++++++++++++++++++++++++++++++++++++

I called the Nova Kool factory last fall when installing our new double door unit. The tech I talked with about installing an aux fan warned me not to exceed .3A total load on their fan pin. Their compressor fan consumes .13A itself leaving only .17A available for a customer supplied fan to remove heat from the coils in tight installations.

We ended up using the control module fan pin to drive a relay to energize both the Nova Kool compressor fan and our own external cooling fan. Pro tip if you go this way: the fan pin (at least on the Nova Kool control module) is active low so the other end of the relay coil needs to be tied to 12V to drive the relay when the compressor turns on. Nova Kool offers their own version of a supplemental relay to drive an external fan if you are not comfortable doing your own "hack".

Regarding resistors to control compressor speeds, our new Nova Kool unit had some early teething pains due to a bad crimp in the stab-on connector of the factory supplied resistor. If the circuit containing that resistor doesn't make continuity, the compressor stops and the fridge/freezer begins to warm. After working with the factory over the phone to troubleshoot our problem and learning more about the variable compressor speeds, we also went with a switch to alternate between several resistor/speed values and plan to use it on a seasonal basis.

I called the Nova Kool factory last fall when installing our new double door unit. The tech I talked with about installing an aux fan warned me not to exceed .3A total load on their fan pin. Their compressor fan consumes .13A itself leaving only .17A available for a customer supplied fan to remove heat from the coils in tight installations.

That's interesting. I thought their literature showed that they used either the Danfoss/Secop BD35 or BD50 compressors. According to Danfoss's literature, as I understand it (the fans attach to their control module), you can add a fan (or fans) drawing up to .5 amp continuously, with 1 amp peak (and possibly higher startup current).

The Noctua fans I got (one to replace the stock noisy/cheap fan that's part of the compressor unit, which I have already done; the other in case I wanted to add a second fan to the space), only draw .14 amps. So even if I add the second one to cool the space, the two together are still only .28 amps total.

Or does Nova Kool use the Danfoss/Secop compressor but then for some reason use their own proprietary control module? (The Danfoss/Secop one is clearly labeled as in the photo in my post above.)

This is from the Danfoss/Secop BD compressor manual:

Attachments

Similar threads

- Replies

- 3

- Views

- 560

- Replies

- 23

- Views

- 2K

- Replies

- 7

- Views

- 960