Just before I decided to start this thread I read the latest few blog posts Wayne posted on his Mobius.world blog, that talks about crossing the Atlantic, and working out how to best rig his paravane stabilizers. I have run boats with both Paravanes and active fins, and have thoughts on both, that were too much for a blog comment. I ended up writing him a long email with my experiences. I am going to excerpt the email I sent him here rather than start from scratch of the topic of stabilizers. He is also planning on posting more in the future about his experience, rigging, and use of his stabilizers, and might include some of my comments as well. I encourage everyone to check out his amazing blog if you haven’t done so already.

https://mobius.world/

Edit- Copy paste did not work as good as I thought it would. It inserted hundreds of ** in the text. I took most of them out, but I am sure I missed a few.

Wayne,

I have been following your blog since you began construction and have enjoyed and envied your project. In the past few years I have owned and ran boats with both paravanes and active fin stabilizers and have thoughts on both that I figured I would share on the off chance you found them helpful in dialing in your new boat. While I have run both systems, it is hard to directly compare them as the boats they were on are very different. My previous boat with the paravanes was a 40’ aluminum trawler that was relatively light, and shallow draft. While my current boat with the active fins is a 56’ heavy displacement, full keel trawler that was based off an old school sail boat hull. While both of them are fairly narrow beam/length compared to most modern trawlers, they are not as extreme as your boat. The 56’ has much more natural stability, than the 40’er, I assume due to the weight, and large full keel (It is slow as a slug too). On the Aluminum boat we used the paravanes almost all the time. Even if flat water around home we often used them as there is lots of traffic around our home waters, and they made other boats wakes so much better that it was worth dragging them around. *We did not have fancy electronics on the boat to record the angles, but the best description I always used, was if you didn’t have them out, and set down a mug of coffee, it would immediately end up spilled or on the floor. With them, it would stay where you put it and not spill. They seemed to slow us down about .5-.75kn when in use. I also made some big plates to use as flopper stoppers while at anchor. We didn’t need them much around here as we have fairly protected anchorages, but a couple times they were really nice. The active fins on my current 56’ boat seem very similar to me in effectiveness to the paravanes, although it is hard to compare directly as the hulls are so different. In rough weather the active fins slow the boat down almost 1kn, which is brutal as it is a slow boat to begin with, and only normally cruises around 5-6kn in ocean crossing mode, and 6-7Kn in costal mode. I bought the boat in Fiji and brought it back to Washington state. During that trip, the distances were so huge, and the hit to boat speed was so big with the stablilizers that we barely used them even though it was very rough. We kept the gain turned way down to 10% most of the time to keep the boat speed up. The nice part was that we could crank the gain up to 100% with the push of a button when we needed to cook something, or do something on deck that needed the boat to me more stable. Around home I always keep them at 100% gain as they don’t slow the boat down much when it is not super rough, and when it is rough the happiness of my wife is much more important than boat speed, and I am less worried about saving fuel as we are not crossing the Pacific.

I am not a good enough writer to put my thoughts into nice paragraphs, So I am just going to make a list.

- I really liked the Paravanes, and felt that they were as effective as the active stabilization, although as I stated before, it is hard to compare as my boats were very different. I would not assume though that active would be more effective than well dialed in paravanes. There were a couple times the paravanes on my boat seemed a little dangerous/sketchy. They involved situations where it was really rough and stormy out but I needed to enter a bay or Marina that was either too narrow, or too shallow to be safe to leave them deployed while entering. My boat was small enough that I didn’t not have them rigged with any winches or blocks to bring up the fish, or bring in the poles. This was ok as I was young, and they were not too big as it was only a 40’ boat. But we did have to put the boat in neutral to do it, and the boat would tend to drift beam to the sea. If it was really rough the boat would wallow like crazy beam to the sea while I was on deck trying to get the fish in and stowed. It did not feel super safe to be out on deck doing it, stuff inside the boat would inevitably be shifting all over the place, and it scared the heck out of my wife. It happened a couple times right outside our home marina that can get a 2kn+ current on an ebb tide and with a strong west wind running against it gets super ugly. And also a couple times coming into inlets off the Pacific on the coast of British Colombia that were relatively shallow and narrow, with big rocks and huge breaking waves on either side. It is the worst time to be out on deck fighting it, as you are so close to danger if something goes wrong. We don’t have Sargasso around the pacific NW, but we have tons of kelp. Surprisingly I have had way more problem with kelp getting stuck between my active fins and the hull, than I ever had with it getting stuck on the paravanes.

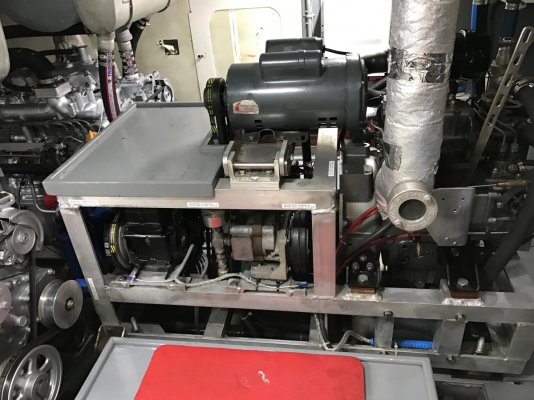

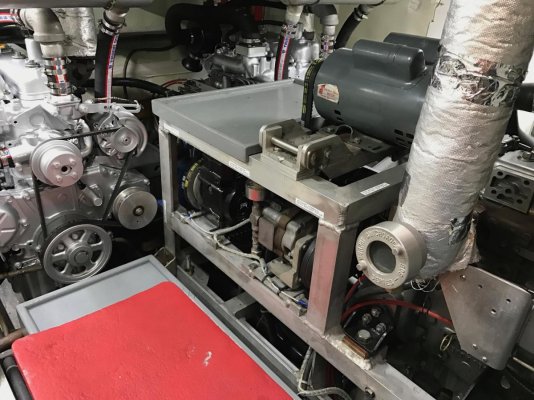

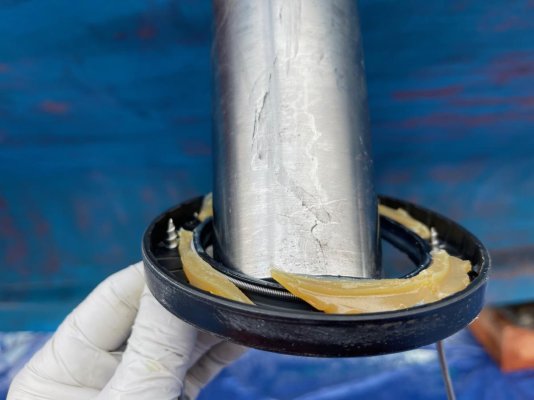

- The active fins are a great system and seem to work well. The things I like about them is that they are super easy to turn on and adjust inside the boat with the push of a button. No going out on deck in a storm to fight them. I also like that they have little drag in calm weather, but still dampen the roll if a big wake comes by. They are much better when entering a bay or marina in really bad weather. I did the seal replacement myself and that was no big deal, and very cheap. (I was fortunate to be able to reach them with my Steelhead dingy crane and use it to lift the heavy fin on and off in the yard. It made it very easy.). The thing I don’t like about them is the complication of having the extensive hydraulic system that it takes to run them. While the system the previous owner had installed on my boat works well, it was not original to the boat and is a bit of a bowl of spaghetti situation in the engine room. It is a lot of pumps, hoses, valves, bypasses, heat exchangers, tanks, wiring, etc. My engine room would he a hell of a lot nicer, and cleaner without all that crap. (My 56’ boat was originally built with paravanes, but the previous owner rendered them unusable as part of a poorly executed refit attempting to add a sailing rig that doesn’t work for a bunch of reasons, and I have since removed.)

- This would probably not be such an issue on your boat, but on my boat, speed was an issue with the active stablilizers. The passage from Fiji to Hawaii, and from Hawaii to Anacortes was at the edge of my boats fuel range, so we were taking it slow to save fuel. The stabilizers did not work as well at slow speeds, I assume they could not develop as much force as the water was not passing over them as fast. It would be something to consider though in the engineering. I would try and size the fins for the speed you think you will be going in the worst upwind conditions. We ended up barely using them anyways just because they slowed us down so much, and 3/4 of a kn seems like a lot when you get out the calculator and figure out how long that is going to cost you at 2500 miles at 5-6kn.

- The spectra line you are using on your fish looks way thicker than what I was using. I know your boat is way bigger, and the loads are higher, but I think it would be worth trying to figure out how small you could safely go. My theory is that the smaller line slices through the water easier, and is more likely to saw through kelp or seaweed that might get stuck on it. I also wanted it to be the weak part of the system in case it ever got caught on a big log or rock. Not that bad to loose a fish, but tearing off the pole and support mast structure would have been a disaster. My boat was rigged with three strand nylon from the pole tip to the waterline, then stainless cable from the waterline to the fish, when I got it. I assume the idea was to have some*stretch to reduce shock loads? I switched it a single piece of Amsteel from the pole tip to the fish, and it seemed way better. I never once had it slam in a way that I though it was experiencing big shock loads.

- I tried retrival lines on the back of the fish similar to how you have them rigged, and for my boat they were more trouble than they were worth. My main complaint was that if I stopped the boat with them on the fish would swim in circles as the boat rocked around, and twist them all up. It was a pain in the ass. I ended up with small retrieval lines that I would just clip over the Amsteel and they would ride just above the water line, then I would tie the other end to the pole just past the railing with a clove hitch. Their only use was so I could pull on them and get the main line in close enough so I could grab it and manually pull the fish up out of the water. Probably not practical on your boat, but it was nice only having only one line in the water. I always had a fantasy of how to set them up, that might be worth thinking about on your boat. First have the poles on pulleys with a winch and line stoppers so you can pull them up when under moderate load (My boat wasn’t rigged this way, but I think yours is.). Then have the fish on a line that runs from the fish, through a very strong block at the end of the pole, down to a sailboat winch*mounted on a plate on the pole near the railing. To get the fish in you would slow the boat down, raise up the pole about 2/3 of the way till the line running down into the water was close enough that you could grab and control it, but far enough away that the fish wouldn’t be right against the hull, then winch the fish up out of the water with one hand using the winch on the pole in front of you, while controlling the fish from swinging into the boat with the other. In rough weather you could leave the pole further out, get the fish at the surface, then reach out and hook it with a boat hook to control it swinging before bringing the pole up further. The other thing I like about this idea is that in a situation like I mentioned previously where you were entering a harbor, that had say a charted depth of 18’, you would probably not want to go in there with your *fish in the water, but if the conditions were not to extreme and you could bring them up so they were only 6-8’ under water it would be fine. The things I worry about with this idea are chafe issues at the block on the end of the pole, the block blowing apart under big load, The winch might not work that great with small Amsteel, and the blocks might be hard to secure so that they don’t bang on the poles when they are up and you are not using them.

- My current boat came with Keypower active stabilizers. They seem very similar to other systems, but there are two things I really like about them. First, their technical service was super responsive and friendly when I was trying to figure the system out when I first got the boat under challenging circumstances, (There was some friction with the guy I bought it from, and he didn’t understand the system anyway,) and also later when I was trying to figure out how to service the seals and order the parts for it. They were great both times. The second thing I like is that the fins are made of molded hard rubber over a stainless frame. The idea is to provide a little bit of shock protection in the event of hitting something. There are tons of logs floating around where we cruise and this seem like a good method of construction.

- I always though gyroscope stabilizers were dumb, but lately when I think about dream boat designs I wonder if there is a path that makes sense where you have paravanes and Gyro. Paravanes would be the go to for long passages, but the gyro could be used along with it during bad weather, or shorter costal hops where setting up the paravanes seems like a pain in the ass, but it would still be nice to have stabilization, and it would also be nice in a crappy anchorage. You would avoid having the big hydraulic system, the fins in the water with their drag and strike danger. It would only make sense if you already had the electrical system to run it, and a decent place to put it. It might be more expensive than I can imagine as well.