firstbase

Guru

- Joined

- Nov 6, 2016

- Messages

- 1,644

- Location

- United States

- Vessel Name

- Black Eyed Susan

- Vessel Make

- Grand Banks 42' Classic

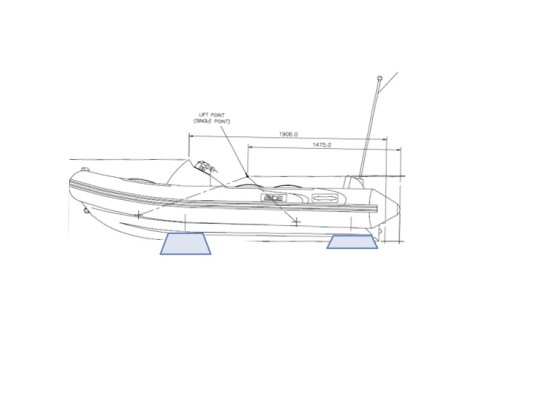

I am reworking my dinghy chocks on the top of the after cabin. Bought a new dinghy and the PO's old setup doesn't work anymore. It's an 8.5' RIB to be stored on deck without the motor.

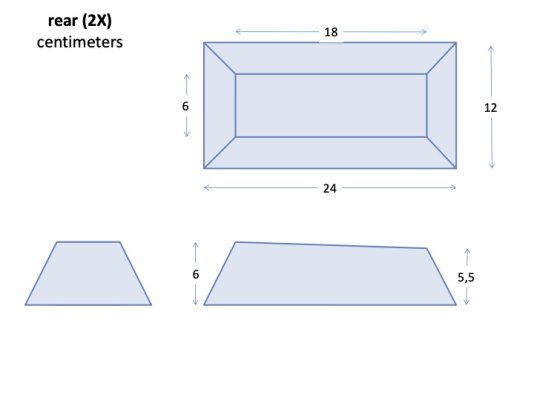

I purchased 4 8" Weaver swivel dinghy chocks. There is a plate to be mounted that allows the actual chock to slide in and out for removal. The plate has 3 holes for screws on each side. My question is what is the best way to mount that flat plate? I have no idea of the thickness of the aft cabin roof (1987 GB 42).

I was thinking about using 3M 5200 under the plate with screws on each side but not sure 1) what length to use without going through the cabin top and 2) what length would be adequate to keep the plate in place.

The other option would be to 5200, or 5200 and screw, in a 2" thick block of wood to the cabin top and attach the plate on top of that block. However, using 5200 and screws would be much the same as just screwing it down w/o the block. The PO's setup uses blocks but they are in the wrong positions. Not sure how they are fastened as he Awlgripped them.

Any suggestions? I'm probably overthinking this!

I purchased 4 8" Weaver swivel dinghy chocks. There is a plate to be mounted that allows the actual chock to slide in and out for removal. The plate has 3 holes for screws on each side. My question is what is the best way to mount that flat plate? I have no idea of the thickness of the aft cabin roof (1987 GB 42).

I was thinking about using 3M 5200 under the plate with screws on each side but not sure 1) what length to use without going through the cabin top and 2) what length would be adequate to keep the plate in place.

The other option would be to 5200, or 5200 and screw, in a 2" thick block of wood to the cabin top and attach the plate on top of that block. However, using 5200 and screws would be much the same as just screwing it down w/o the block. The PO's setup uses blocks but they are in the wrong positions. Not sure how they are fastened as he Awlgripped them.

Any suggestions? I'm probably overthinking this!