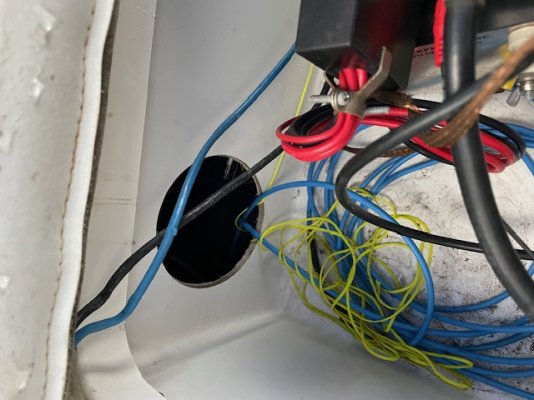

To J T Kearney, I'll try to get that picture today. Just got back from a convention. I'ts pretty simple, just in the floor aligned roughly with where the cables go down by the Stbd window. It allows you to put a cable pull thru the large hole below the instrument console and catch it at the hole, then you can put the cable pull thru the hole in the side bench and send it down by the window to the instrument console in the salon. I had to run a couple antenna wires and cable for a remote for the auto pilot, some 110vac lines to put AC at the flybridge, etc. I wanted AC outlets on the bridge for phone chargers etc. Anyway, there's no way I could get all those cables thru the rubber hose that most of the cables are run from the factory.