Max1

Senior Member

- Joined

- Sep 14, 2021

- Messages

- 404

- Vessel Name

- Bermuda Belle

- Vessel Make

- Marine Trader 36 Sedan

Next I want to talk about the galley.

Here is a photo of the galley as it appeared when we purchased the boat. In the bottom left is a bar fridge, 110 volt ac. It didn't fit properly and we weren't sure how we were going to power it. In the center the two large doors open to a cavernous space. There were no shelves and no organization whatsoever. Basically whatever you put in there we'll just go to the ground level. The doors underneath the stove were equally useless. Basically the entire cabinet behind both sets of doors was one big space. No shelves no nothing. Very awkward to store anything. Where is the cutlery to be kept?

One of the first things we wanted was a larger fridge. The fridge would have to go on the far right so that it butts up against the High counter that I guess is the dash of the boat. That leaves us with the remaining space for cabinetry. In my previous posts I show the 12V fridge that we ended up purchasing in February 2022. With the dimensions of the fridge in hand, the only place it was going to go was on the far right. So that was our staring point.

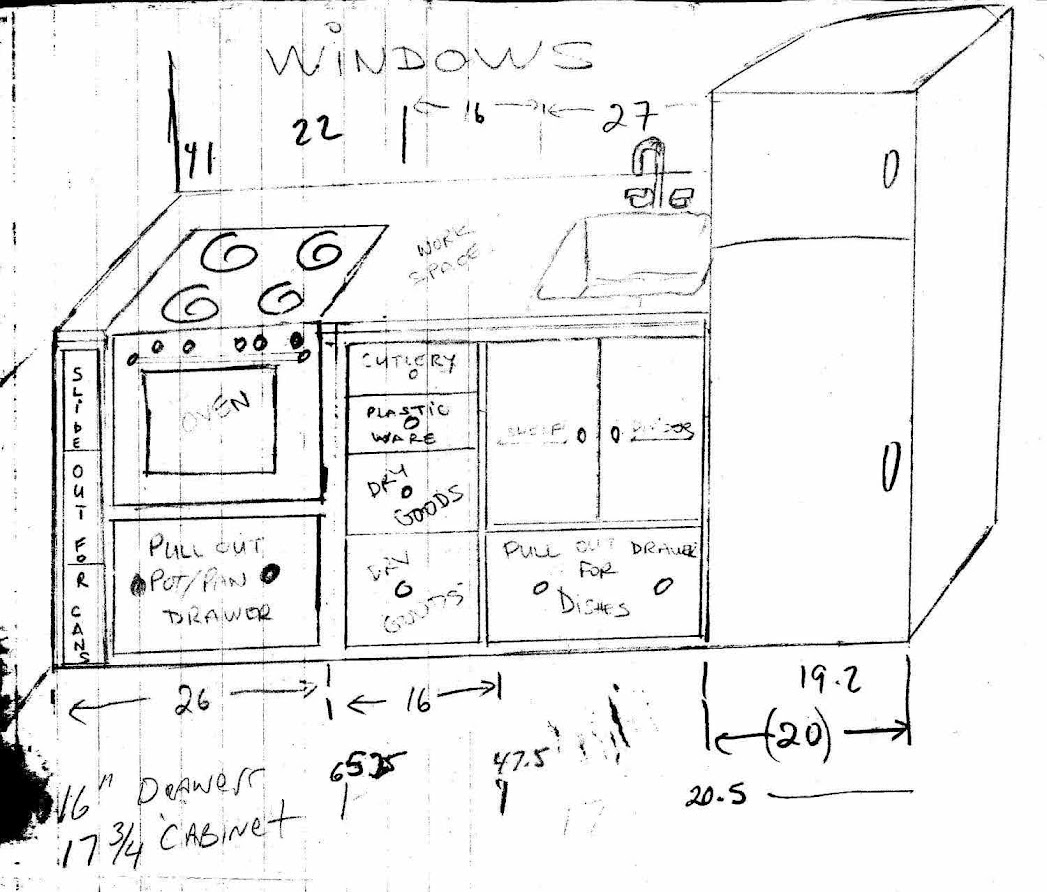

One of the prerequisites for my wife was to have some sliding drawers for cutlery utensils etc etc. We happened to be at our local re-store and found a kitchen cabinet with four drawers. We purchased that for about 20 bucks. With the dimensions of the fridge, stove and drawers in hand, the Admiral came up with the initial concept for what our kitchen would look like. Sketch one.

In this initial concept, we wanted a slide out on the left for cans, then the stove, then the sliding drawers, and the remaining space (whatever Dimensions was left over) would be would be for some kind of cabinets under the sink.

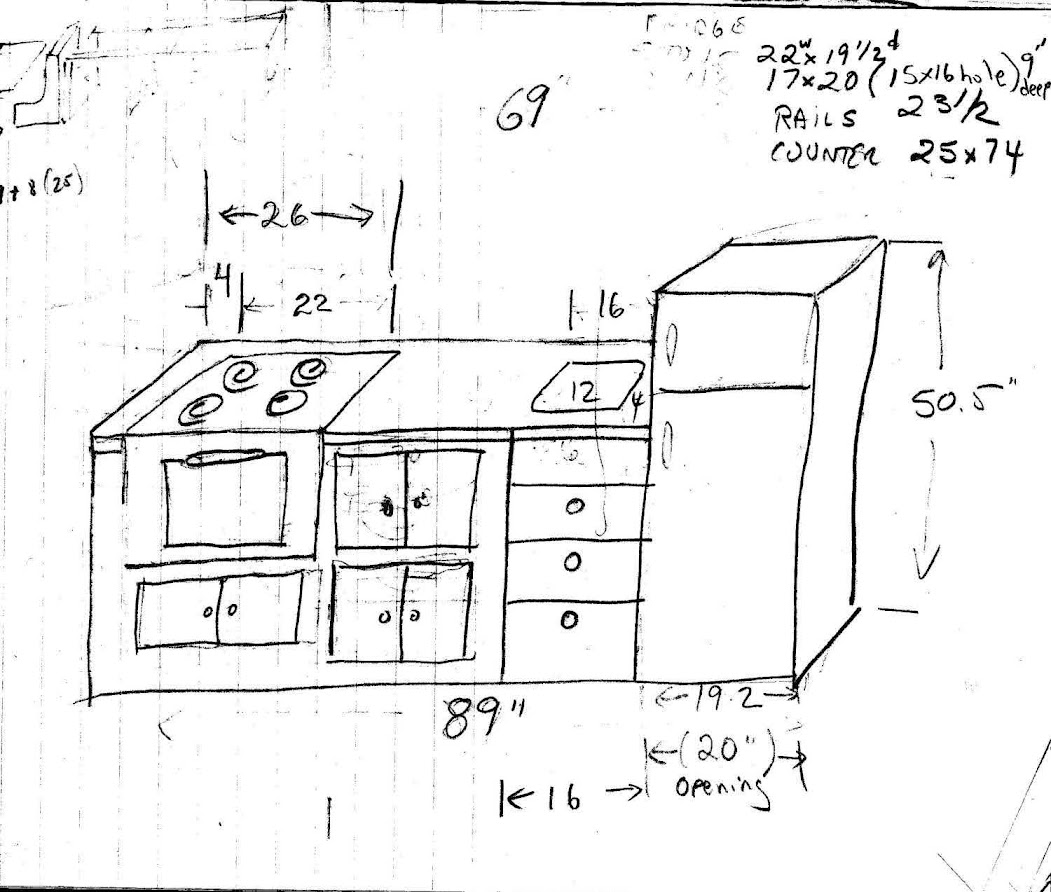

The second option was to have the sliding drawers adjacent to the fridge and push the stove to the far left. This would maximize counter space. We were also thinking of maximizing the counter space by having the sink directly over the sliding drawers. This would mean sacrificing the first drawer in the cabinet and some creative plumbing, but we would still have three drawers remaining and a large counter space.

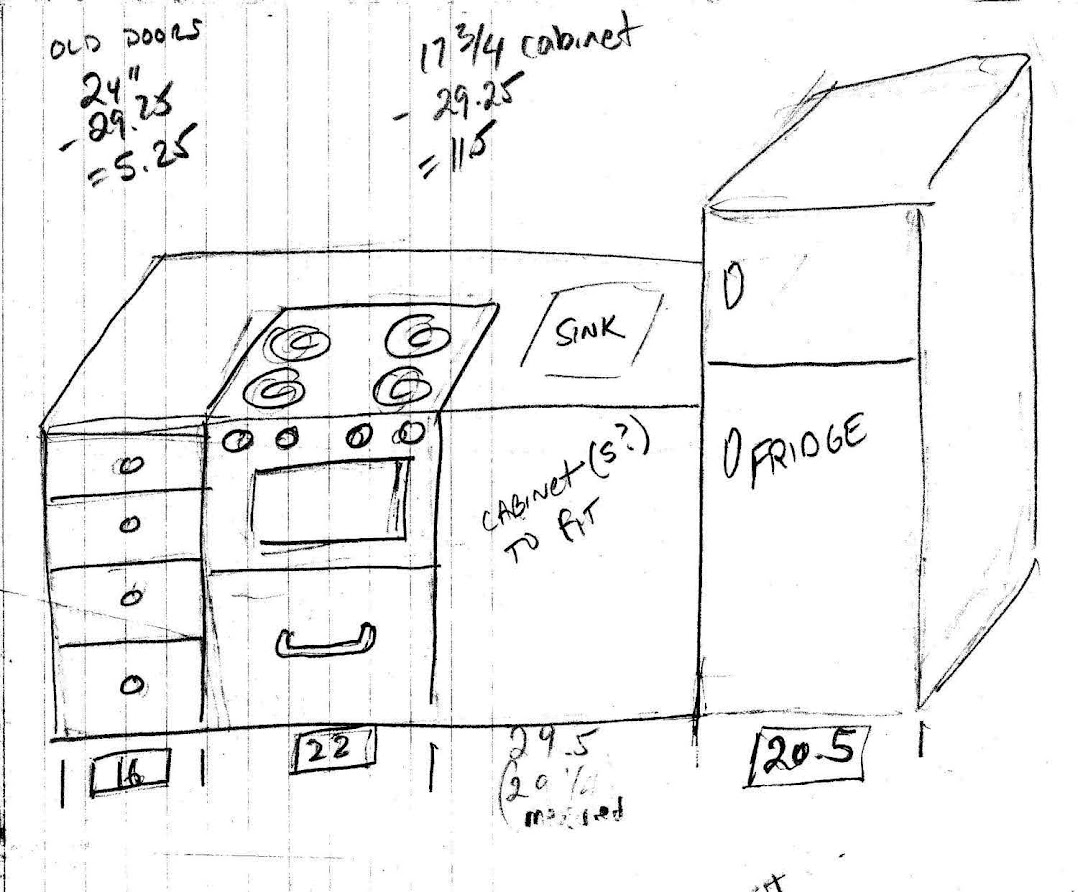

This is the final concept we came up with and what we eventually installed in the boat in the spring of 2022. We put the sliding drawers on the far left with the stove adjacent to it, then the cabinets and the sink between the stove and the fridge. We knew the dimensions of the drawers, the stove, and the fridge. That left us with whatever was left for cabinets. Not knowing what cabinets we were going to get, we just left this as a potential Improvement area. More Galley updates in the next post!

Here is a photo of the galley as it appeared when we purchased the boat. In the bottom left is a bar fridge, 110 volt ac. It didn't fit properly and we weren't sure how we were going to power it. In the center the two large doors open to a cavernous space. There were no shelves and no organization whatsoever. Basically whatever you put in there we'll just go to the ground level. The doors underneath the stove were equally useless. Basically the entire cabinet behind both sets of doors was one big space. No shelves no nothing. Very awkward to store anything. Where is the cutlery to be kept?

One of the first things we wanted was a larger fridge. The fridge would have to go on the far right so that it butts up against the High counter that I guess is the dash of the boat. That leaves us with the remaining space for cabinetry. In my previous posts I show the 12V fridge that we ended up purchasing in February 2022. With the dimensions of the fridge in hand, the only place it was going to go was on the far right. So that was our staring point.

One of the prerequisites for my wife was to have some sliding drawers for cutlery utensils etc etc. We happened to be at our local re-store and found a kitchen cabinet with four drawers. We purchased that for about 20 bucks. With the dimensions of the fridge, stove and drawers in hand, the Admiral came up with the initial concept for what our kitchen would look like. Sketch one.

In this initial concept, we wanted a slide out on the left for cans, then the stove, then the sliding drawers, and the remaining space (whatever Dimensions was left over) would be would be for some kind of cabinets under the sink.

The second option was to have the sliding drawers adjacent to the fridge and push the stove to the far left. This would maximize counter space. We were also thinking of maximizing the counter space by having the sink directly over the sliding drawers. This would mean sacrificing the first drawer in the cabinet and some creative plumbing, but we would still have three drawers remaining and a large counter space.

This is the final concept we came up with and what we eventually installed in the boat in the spring of 2022. We put the sliding drawers on the far left with the stove adjacent to it, then the cabinets and the sink between the stove and the fridge. We knew the dimensions of the drawers, the stove, and the fridge. That left us with whatever was left for cabinets. Not knowing what cabinets we were going to get, we just left this as a potential Improvement area. More Galley updates in the next post!

Last edited:

I would want no voids in under the final covering.

I would want no voids in under the final covering.