GoldenDawn

Senior Member

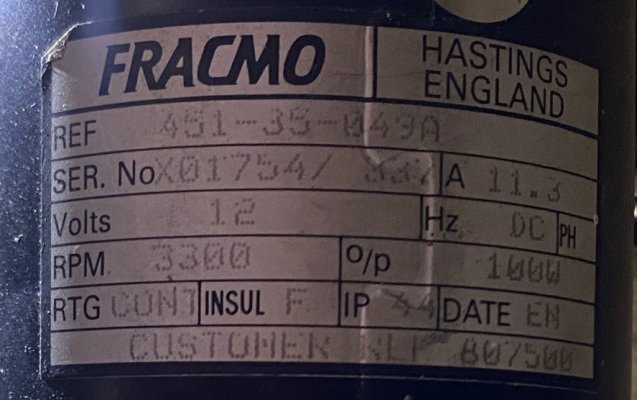

For a few months, I have been experiencing an intermittent problem with my ComNav autopilot. When the pump sits for a while - a few days or more - it "freezes". I can hear the motor engaging but it does not run. A few whacks with a rubber mallet frees it, and then it runs normally. The electric motor is a 12vDC FRACMO (see photo). Any ideas on the issue?

My troubleshooting started by checking the motor brushes. With the brush cap off and brush spring exposed (see close-up of spring), the spring and brush are refusing to come out. For now, I have replaced the cap, wondering how hard I should tug the spring or if there is another intervention?

My troubleshooting started by checking the motor brushes. With the brush cap off and brush spring exposed (see close-up of spring), the spring and brush are refusing to come out. For now, I have replaced the cap, wondering how hard I should tug the spring or if there is another intervention?