You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

fuel polishing

- Thread starter lipets

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,296

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Is polishing needed? No. Is it a worthwhile upgrade? Depends on personal risk tolerance which will be influenced on how you use the boat. Polishing reduces risk of clogged filters and unexpected engine shutdown.

An oversized Racor makes a decent polishing filter medium. A well designed polishing system inckudes a high volume pump to create turbulence in the tank. A system that can be used underway is a bit more complicated as it requires separate inlet/outlet into the tank(s).

Personally, I had a polishing system installed. But my first line of defense for years was a dual Racor primary filter housing.

Good with whatever you decide.

Peter

An oversized Racor makes a decent polishing filter medium. A well designed polishing system inckudes a high volume pump to create turbulence in the tank. A system that can be used underway is a bit more complicated as it requires separate inlet/outlet into the tank(s).

Personally, I had a polishing system installed. But my first line of defense for years was a dual Racor primary filter housing.

Good with whatever you decide.

Peter

Last edited:

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,419

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

I think it depends on where you get your fuel. If you use high volume sellers, probably not. If you don’t maintain the O rings on your deck filler fittings, probably yes. I have never had a fuel issue and really don’t even get clogged Racors without any fuel polishing at all. But I do buy at reputable fuel docks and keep the O rings replaced when needed.

RT Firefly

Enigma

Greetings,

In the 18+ years we owned Savasa we never had ANY issues with water or detritus in our single Racors and we were out in some quite sporty seas. The new owner who is simply flipping the boat for an exorbitant mark-up ($$$) , evidently had the fuel polished and has mentioned such in the new listing as a selling point. Go figure.

In the 18+ years we owned Savasa we never had ANY issues with water or detritus in our single Racors and we were out in some quite sporty seas. The new owner who is simply flipping the boat for an exorbitant mark-up ($$$) , evidently had the fuel polished and has mentioned such in the new listing as a selling point. Go figure.

Lollygag1

Guru

- Joined

- Aug 23, 2016

- Messages

- 875

- Location

- US

- Vessel Name

- Lollygag

- Vessel Make

- 34 Mainship Pilot Hardtop

We had a persistent issue of fuel tanks not balancing, tried replacing filters and other items to no success. Finally had someone suggest we have the fuel polished. Bingo problem solved.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,934

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

It depends on where you go, where you buy fuel, and how bad it would be if your engine(s) shut down. If your you're going up and down the AICW (Atlantic Inter Coastal Waterway) probably will only be an inconvenience. If you plan to cross the Atlantic, Gulf of Mexico, or the wilds of Alaska, maybe it's a higher priority. Go visit BoatUS, and check the top reasons for engine failure. The way I look at it, what percentage of the time would engine shutdown put you at great risk? If it's less than 1%, maybe not so important. 10% (1 hour out of every 10) might justify spending less that a boat unit ($1,000).

Ted

Ted

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,490

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

Buying from high volume distributors reduces the risk greatly. But it isn't 100% trouble free. Good filtration is important. Dual with selector valve makes dealing with bad fuel easy while underway. A good quantity of spare elements will see you through the rough patch.

For decades I purchased fuel from a high volume supplier who sells to the tugs and the fishing fleet. They also supply the smaller vendors in the area. Almost all of the time we had no issues. But occasionally they would have problems so we would too. I got a bad load one time and ended up swapping and changing filters about as fast as I could for hours until the main engine had moved enough fuel to clean up the mess.

For decades I purchased fuel from a high volume supplier who sells to the tugs and the fishing fleet. They also supply the smaller vendors in the area. Almost all of the time we had no issues. But occasionally they would have problems so we would too. I got a bad load one time and ended up swapping and changing filters about as fast as I could for hours until the main engine had moved enough fuel to clean up the mess.

Lollygag1

Guru

- Joined

- Aug 23, 2016

- Messages

- 875

- Location

- US

- Vessel Name

- Lollygag

- Vessel Make

- 34 Mainship Pilot Hardtop

Since our issue was due to sludge in one tank the only reason I could think the problem occurred was that the boat had sat for two years before we bought it. While I always noticed the tanks did not balance I was able to fix the issue by changing filters. It was not till this season where I found the port tank did not drain at all. So when we polished the fuel in that tanks we got the sludge out. I think this issue just built up until it prevented any fuel flow thru that one line. Yeah $1000 bucks but no more list after a long cruise

Delta Riverat

Guru

- Joined

- Feb 16, 2022

- Messages

- 870

- Vessel Name

- Dream Catcher

- Vessel Make

- 1979 Island Gypsy 44 Flush Aft Deck

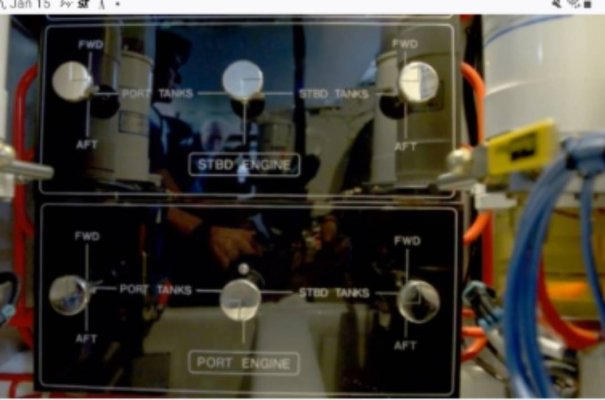

I just did the polish thing a couple months ago. Not to polish the fuel but to transfer from the low tanks to the high tanks in preparation for filling the low tanks. Four tanks for 2 diesels and a 8 valve feed/return board and 4 (2 for each engine) pump or tank select and engine or return select. Lotta stuff going on in the engine room.

Got the electric pumps and the valves figured out. Was cool to hear the fuel dribbling into the transfer tanks. Takes a long time too, those little pumps don't pump a lot of volume.

Got the electric pumps and the valves figured out. Was cool to hear the fuel dribbling into the transfer tanks. Takes a long time too, those little pumps don't pump a lot of volume.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,296

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

FYI - decent blog post from MV Dirona on Nordhavn's approach to fuel management and manifolds. Honestly, I think it's a bit confusing, but better than separate valves.

https://mvdirona.com/2013/12/dirona-fuel-manifold/

Peter

https://mvdirona.com/2013/12/dirona-fuel-manifold/

Peter

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,490

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

I designed a similar manifold system for a friend's boat to replace a collection of 3 valves at each "decision point" scattered around the engine room. I thought it an elegant solution. Everything labeled, all in one place. Lines traceable visually. Something I'd always wanted. He was confused so I had to make a chart for his use.FYI - decent blog post from MV Dirona on Nordhavn's approach to fuel management and manifolds. Honestly, I think it's a bit confusing, but better than separate valves.

https://mvdirona.com/2013/12/dirona-fuel-manifold/

Peter

The most user friendly fuel manifold I've seen is on a Flemming 55. So easy to use but everything is out of sight behind the panel. I don't like secrets.

Iggy

Guru

I don't know if this is worth mentioning for boaters like myself that are new to diesels.

Two years ago I bought my trawler and my first diesel. I knew that the racor filter needed to be changed on the test run before buying the boat. I cleansed and rebuilt the duel filter bowls. Got a lot of crap out. Took the boat home 8 mile run in rough seas. Changed the filter again, it was dirty. Oh, in all this time the engine ran great. Took the boat later from Boston so L.I. New York. Another filter change and went back home and yes another filter and took the bowl apart and cleaned it.

Now I bought a fuel polishing system! I lucked out that there was a unused valve at the bottom of the tank so I used that. The system pulled 80gph and run it for 8 hours to I turn the fuel over 2 times if not more. The filter was a little dirty and I thought I was OK.

Now the 2nd year the some thing was happening but not as bad after doing runs. Point being, or at lest for me. That the tanks needed to be stirred before fuel polishing and within hours before the crap settles.

Two years ago I bought my trawler and my first diesel. I knew that the racor filter needed to be changed on the test run before buying the boat. I cleansed and rebuilt the duel filter bowls. Got a lot of crap out. Took the boat home 8 mile run in rough seas. Changed the filter again, it was dirty. Oh, in all this time the engine ran great. Took the boat later from Boston so L.I. New York. Another filter change and went back home and yes another filter and took the bowl apart and cleaned it.

Now I bought a fuel polishing system! I lucked out that there was a unused valve at the bottom of the tank so I used that. The system pulled 80gph and run it for 8 hours to I turn the fuel over 2 times if not more. The filter was a little dirty and I thought I was OK.

Now the 2nd year the some thing was happening but not as bad after doing runs. Point being, or at lest for me. That the tanks needed to be stirred before fuel polishing and within hours before the crap settles.

Last edited:

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,934

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

Now the 2nd year the some thing was happening but not as bad after doing runs. Point being, or at lest for me. That the tanks needed to be stirred before fuel polishing and within hours before the crap settles.

While I generally try to avoid crappy days and beam sea, when faced with several hours of of lumpy travel, the polisher gets turned on. Mine will turn one of the tanks over every 2 hours if full. Though I imagine that the agitation effect is significantly better between a quarter and a half a tank.

Ted

twistedtree

Guru

I think there are two distinct situations that you need to consider. First is dealing with a long accumulation of crud in your tanks, and the second is “I have clean tanks but just filled with a bad batch of fuel”.

If you have accumulated crud in your tanks, the only way the get rid of it is to open up and clean the tanks. A “polisher” to do this requires high flow since you are essentially pressure washing your tanks with circulating fuel. And you need to direct the fuel spray right on the crud to dissolve and dislodge it. Nobody’s inboard polisher can do this.

An onboard polisher comes into play when you get a bad load of fuel. If you can circulate and filter the fuel while the crud is still in suspension, then you can get it out. But keep in mind that just running your engine(s) does the same thing. The difference is that a polisher might move fuel faster then an engine, and you can stop and change filters without stopping the engine. That said, some engines move close to or the same rate of fuel as polishers, and with duplex filters you can change also change filters without stopping the engine.

If you have accumulated crud in your tanks, the only way the get rid of it is to open up and clean the tanks. A “polisher” to do this requires high flow since you are essentially pressure washing your tanks with circulating fuel. And you need to direct the fuel spray right on the crud to dissolve and dislodge it. Nobody’s inboard polisher can do this.

An onboard polisher comes into play when you get a bad load of fuel. If you can circulate and filter the fuel while the crud is still in suspension, then you can get it out. But keep in mind that just running your engine(s) does the same thing. The difference is that a polisher might move fuel faster then an engine, and you can stop and change filters without stopping the engine. That said, some engines move close to or the same rate of fuel as polishers, and with duplex filters you can change also change filters without stopping the engine.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,934

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

If you have accumulated crud in your tanks, the only way the get rid of it is to open up and clean the tanks. A “polisher” to do this requires high flow since you are essentially pressure washing your tanks with circulating fuel. And you need to direct the fuel spray right on the crud to dissolve and dislodge it. Nobody’s inboard polisher can do this.

I would say it depends on what you've accumulated. If you have an organic growing in your tank, it will require surface cleaning either with a pressure wand or wiping the tank down with rags to remove the accumulation from walls, baffles, and bottom of the tank. However, stuff such as asphaltene and other inorganics usually come out with agitation and fuel polishing. Water will also be removed by fuel polishing if the draw is at the lowest point of the tanks.

Ted

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,296

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

I think this is a good point. My boat carries something over 400 gals of diesel but burns around 1 gph. While I have the traditional risk of water via deck fills, precipitation of alphaltines is a concern. My hope is regular circulation of fuel will help (couldn't hurt).I would say it depends on what you've accumulated. ......stuff such as asphaltene and other inorganics usually come out with agitation and fuel polishing.

Peter

Iggy

Guru

I wish my polisher was built in. I really don't have the room. My unit is 18x16". I should have made one!! But I used the tap from the bottom of the tank and the return I ran the hose to the fuel full thur hull. It was too easy doing it that way vs running it back and tapping into the tank for the return.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,934

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

I wish my polisher was built in. I really don't have the room. My unit is 18x16". I should have made one!! But I used the tap from the bottom of the tank and the return I ran the hose to the fuel full thur hull. It was too easy doing it that way vs running it back and tapping into the tank for the return.

If you decide to build it in, often you can tee a return fuel line from the engine, generator, or vent line.

Ted

Iggy

Guru

If you decide to build it in, often you can tee a return fuel line from the engine, generator, or vent line.

Ted

If I did tee off to a return line. I will need a valve so the return fuel goes not go back to the engine or genset? Yes?

Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,139

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

The biggest benefit to my fuel polishing system is the use of the little transfer pump. Besides being able to transfer side-to-side through the Racor (polishing), I can pressurize the line to the engine. Nice when changing the secondary system, or if leaking/lacking fuel to the engine (or generator before I removed it). I don't worry about pushing fuel to eliminate a list. I don't worry much about bad fuel with a double Racor system and double secondaries. I would worry about pressurizing the fuel line if I had to use the little engine-mounted finger pump to prime the engine or chase bubbles out of the fuel line.

My most important use to date of my "fuel polishing system" was when a tank started a little weeping leak. Fortunately, my tanks were sufficiently empty such that I could transfer all fuel to the good tank. It didn't immediately fix things, but reduced the leak to a manageable level prior to repair.

My most important use to date of my "fuel polishing system" was when a tank started a little weeping leak. Fortunately, my tanks were sufficiently empty such that I could transfer all fuel to the good tank. It didn't immediately fix things, but reduced the leak to a manageable level prior to repair.

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,296

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

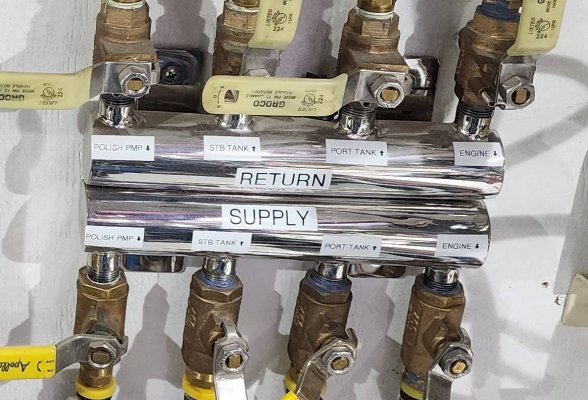

Heart of my fuel management system is this manifold. Its pretty intuitive and allows for decent management of fuel. Once everything is done, I'll have engraved tags made for this and many other items on boat.I designed a similar manifold system for a friend's boat to replace a collection of 3 valves at each "decision point" scattered around the engine room. I thought it an elegant solution. Everything labeled, all in one place. Lines traceable visually. Something I'd always wanted. He was confused so I had to make a chart for his use.

The most user friendly fuel manifold I've seen is on a Flemming 55. So easy to use but everything is out of sight behind the panel. I don't like secrets. View attachment 135119

Peter

Last edited:

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,068

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

This came in over email this morning. Good timing:

https://www.powerandmotoryacht.com/...75A&utm_content=241438976&utm_source=hs_email

https://www.powerandmotoryacht.com/...75A&utm_content=241438976&utm_source=hs_email

rgano

Guru

- Joined

- Oct 8, 2007

- Messages

- 5,012

- Location

- USA

- Vessel Name

- FROLIC

- Vessel Make

- Mainship 30 Pilot II since 2015. GB-42 1986-2015. Former Unlimited Tonnage Master

While I did install a polishing system on my trawler, I have not done so on my MS Pilot because of the higher volume of fuel flow. The old trawler's engines sipped fuel and returned little while the Pilots single engine runs 22 gallons an hour through the system at cruise, including both what is burned and what is returned. The tanks draw from the aft, bottom ends (bow is always high when I am at cruise speed. With a pair of Racors with 2-micron filters and vacuum gauge at the helm, I am pretty well set up to polish fuel and monitor the effects on the filters without all the additional equipment of a dedicated polisher.

bobc

Senior Member

I built my own polishing system using a spare Racor and a carbonator pump. I've been using it for almost a decade now. In all of that time I can't say that I've ever had bad fuel, or even water in the tank. That said, I like having the system for two reasons.

First, if I haven't run the boat in a while, I run the polisher for a few minutes while I'm doing my engine room checks, just to pick up anything that might otherwise be sucked up by the engine fuel system on startup.

Second, I sometimes use it to fill one tank from the other with fuel I know is good before buying fuel. If the new fuel is bad, I know I have one tank with fuel that is known to be good. Also, it's just a lot easier at the fuel dock if I only have to fill the dockside tank.

The pump and motor I bought from Grainger. The pump is a 6XE80 rated for 60GPH flow -- that max rating for the Racor filter. The 1/4 HP AC motor is a 5XB85. At the time the pump, motor and v-band clamp came to about $220. I wired it with a attic-fan timer switch, which I always turn off before leaving the boat.

First, if I haven't run the boat in a while, I run the polisher for a few minutes while I'm doing my engine room checks, just to pick up anything that might otherwise be sucked up by the engine fuel system on startup.

Second, I sometimes use it to fill one tank from the other with fuel I know is good before buying fuel. If the new fuel is bad, I know I have one tank with fuel that is known to be good. Also, it's just a lot easier at the fuel dock if I only have to fill the dockside tank.

The pump and motor I bought from Grainger. The pump is a 6XE80 rated for 60GPH flow -- that max rating for the Racor filter. The 1/4 HP AC motor is a 5XB85. At the time the pump, motor and v-band clamp came to about $220. I wired it with a attic-fan timer switch, which I always turn off before leaving the boat.

Last edited:

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,490

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

That is a nice, clean easy to understand and use manifold system. The one I designed for my friend is more like yours than Diorna's. He has a single main, generator, hydronic heater and transfer/polisher. All fed by two tanks.

For anyone considering building one for a tight space think about using T handle valves. The handles won't overlap each other making it easier to use.

For anyone considering building one for a tight space think about using T handle valves. The handles won't overlap each other making it easier to use.

Heart of my fuel management system is this manifold. Its pretty intuitive and allows for decent management of fuel. Once everything is done, I'll have engraved tags made for this and many other items on boat.

Peter View attachment 135134

Attachments

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,296

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

That is a nice, clean easy to understand and use manifold system. The one I designed for my friend is more like yours than Diorna's. He has a single main, generator, hydronic heater and transfer/polisher. All fed by two tanks.

For anyone considering building one for a tight space think about using T handle valves. The handles won't overlap each other making it easier to use.

I thought about T-Handle valves but could not find enough of them (I had a difficult time finding enough of the 3/8" ball valves). Reverso makes a nice one though it's pretty pricey. Possibly not a bad deal once you factor in all the parts, but strikes me as expensive at $400 (HERE)

Although the polished stainless on mine looks great, I'd go with an aluminum billet from McMaster or similar. HERE is their version of a 4-port manifold body - this model has extra spacing between the outlet ports. about $32/each. Would be a lot of valves but well organized and intuitive. And a crossover line between the pairs could be installed with a valve that is normally closed (bleeding the engine would be an example of when the crossover would be opened - pump would only pressurize one side). Speaking of pressurising for priming, I have a small Walbro plumbed separately. The Groco Puppy pump seemed awfully big to prime an engine with.

Peter

Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

Some engines shift enough fuel through the filters that they are a polishing system

Our 855 puts something like 350 litres/hour through the filters but we only burn 15 litres/hour

Our 855 puts something like 350 litres/hour through the filters but we only burn 15 litres/hour

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,490

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

I used to run a boat with a Cat 379. Like yours that one was it's own polishing system.Some engines shift enough fuel through the filters that they are a polishing system

Our 855 puts something like 350 litres/hour through the filters but we only burn 15 litres/hour

mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,296

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

Thats a lot of recirculating fuel!!! Guessing the fuel tanks got pretty warm.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,419

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

I don’t know what my 6CTAs return but they have fuel coolers on them. Don’t know if they are necessary or not.

Similar threads

- Replies

- 84

- Views

- 5K