Most of us at one time or another have faced the problem of getting into a slip or getting on or on a dock when the wind and/or current is doing its best to keep us from accomplishing what we want.

Many years ago a good friend of mine taught me a few tricks about making those maneuvers much easier. When most of us think of spring lines we think of the lines we use when the boat is in the slip to keep it in a certain position in the slip so the wind doesn’t move it around.

There is a whole new usage for the term “spring lines” and that’s what friend taught me. So I thought I’d share some of these tips with all of you.

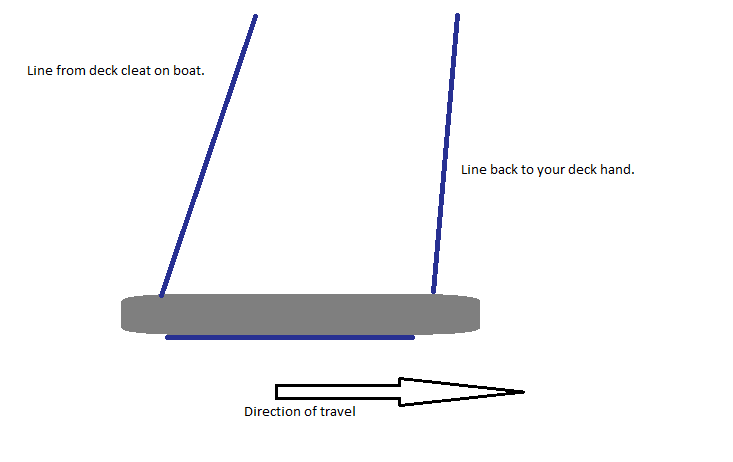

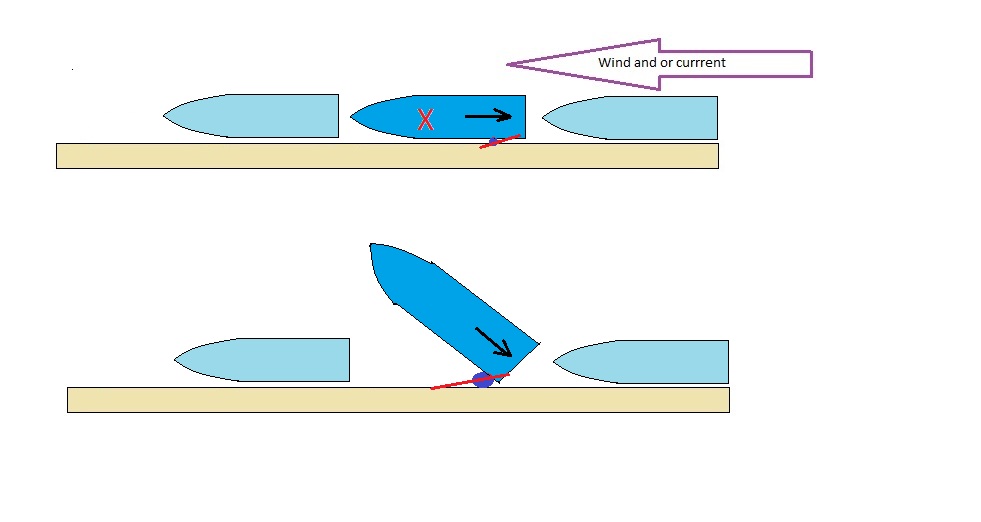

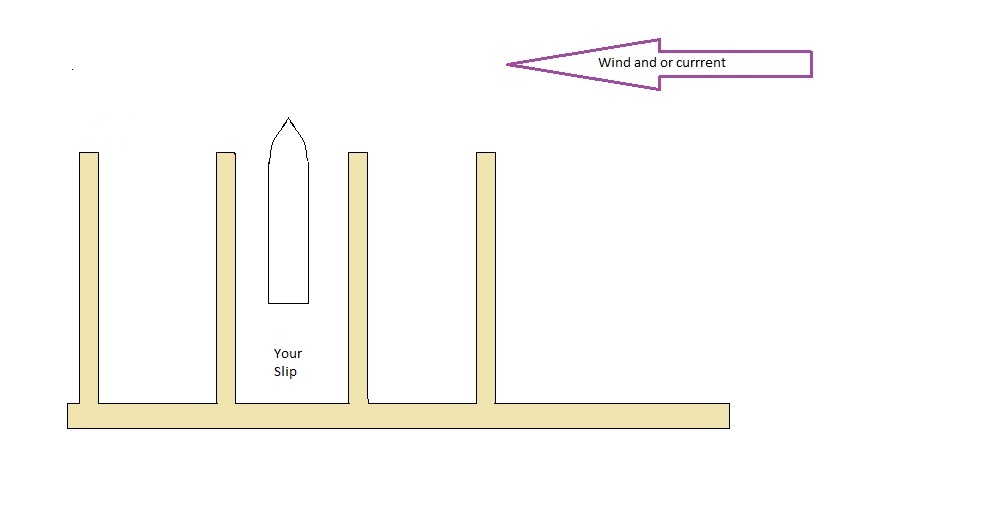

First is the situation where you have to back into a slip and you’re going to have to bring the bow around against the wind, as shown below. Tie a spring line between the aft most cleat on your boat and have it looped just half way around a corner cleat on the dock. Someone needs to be standing there holding tight to the line so that on your command they can remove the line from the dock cleat. One secret to all of these spring line situations is to have adequate fenders between your boat and the dock.

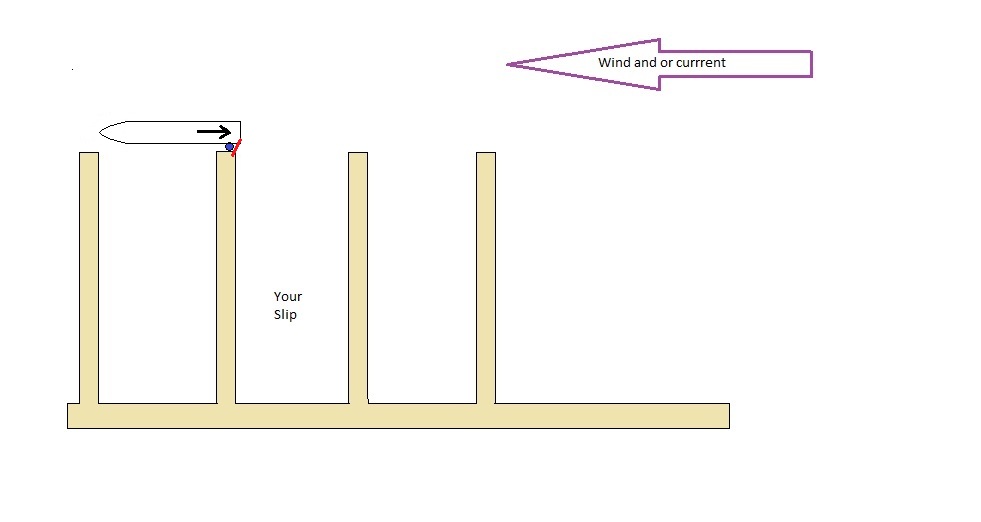

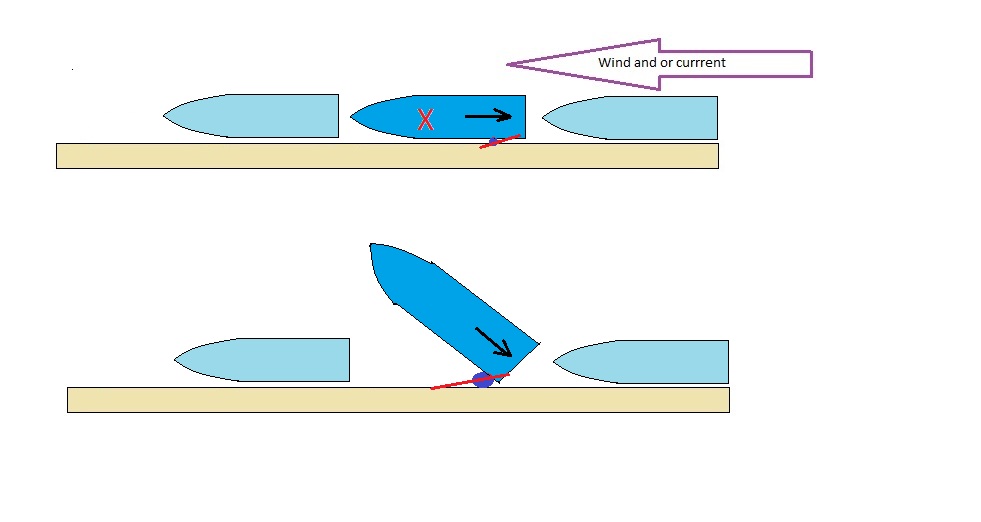

As you put the boat’s stbd engine in reverse the boat will start to back up until the line goes taut. As you continue in reverse, the stern will start to pivot into the slip and the bow will come around into the wind.

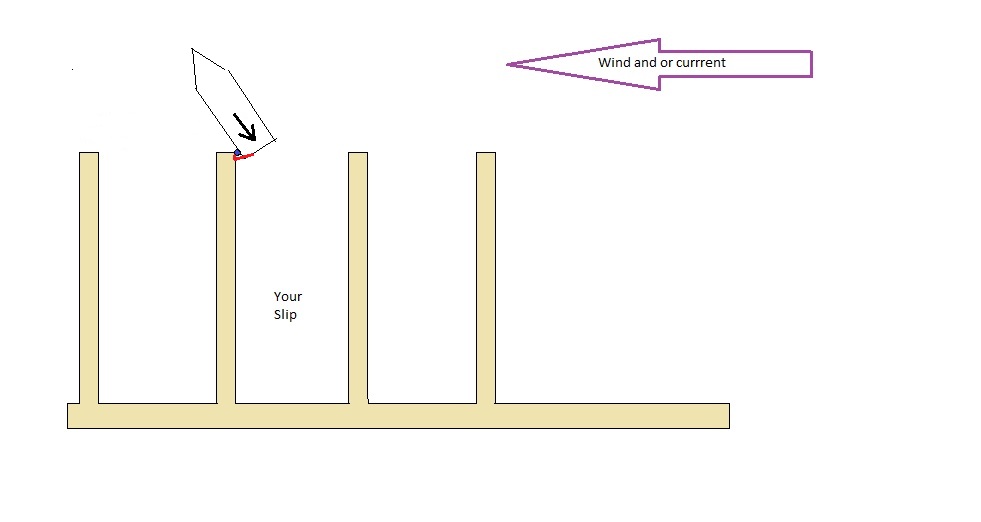

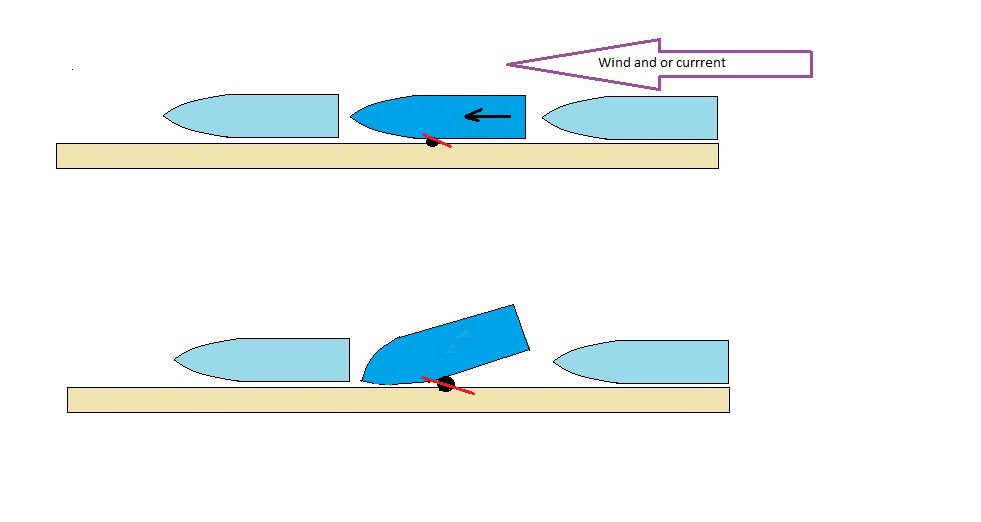

The boat will continue to pivot around the corner of the dock.

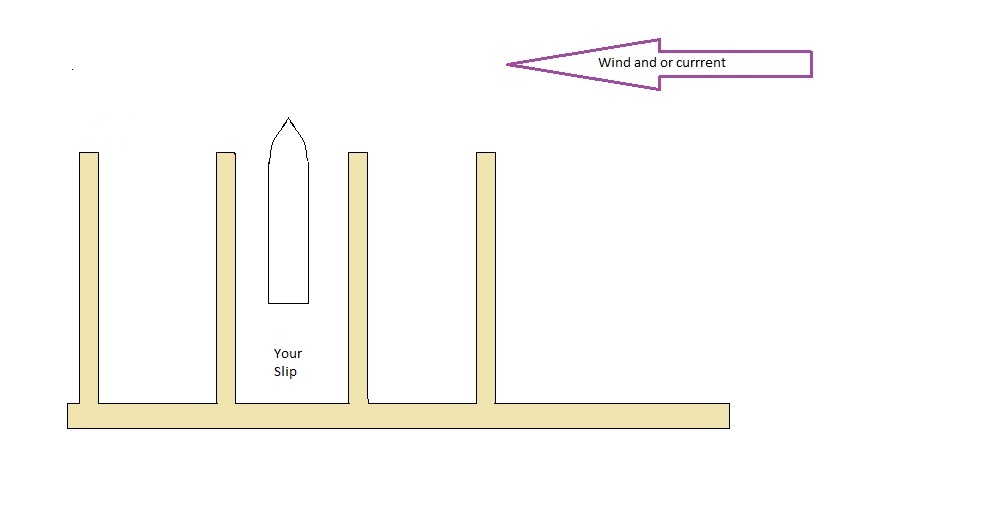

As the boat starts to align with the slip, tell the person holding the line to let it come off the dock cleat and then back the boat in. You want to make sure you have plenty of fenders along your port side because the wind is going to hold it onto the dock.

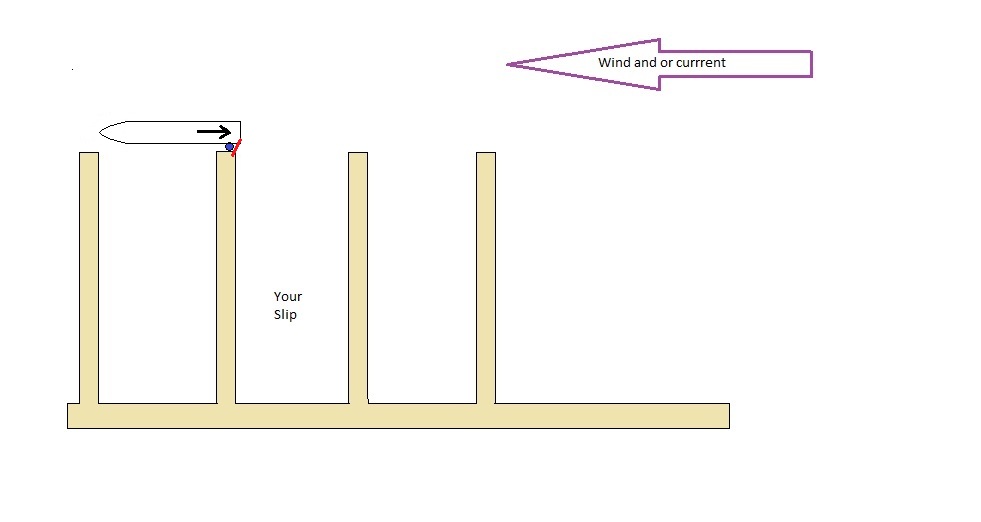

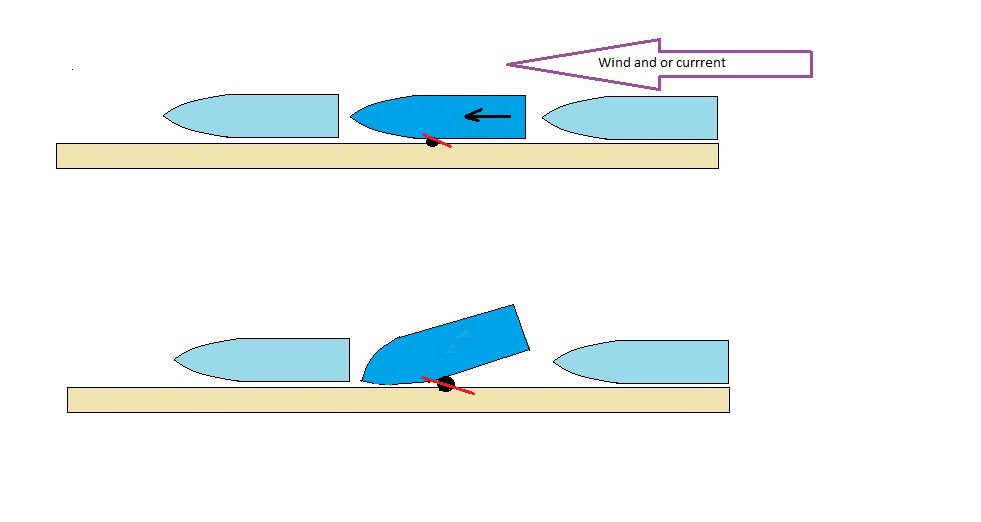

The next scenario where spring lines are helpful is getting off a dock where space fore and aft is tight so you can’t go back or forward to swing out from the dock.

Here you want to swing the bow out from the dock. Put a line from a cleat near your stern to a cleat on the dock that is near the stern. Again, just go half way around the dock cleat so the line can be released in a hurry. As you go in reverse (stbd engine only) the line will go taut and the stern will pivot in toward the dock. The bow will swing out from the dock and when you feel it’s far enough out from the dock, let the person holding the line to remove it from the dock cleat so you can then go forward.

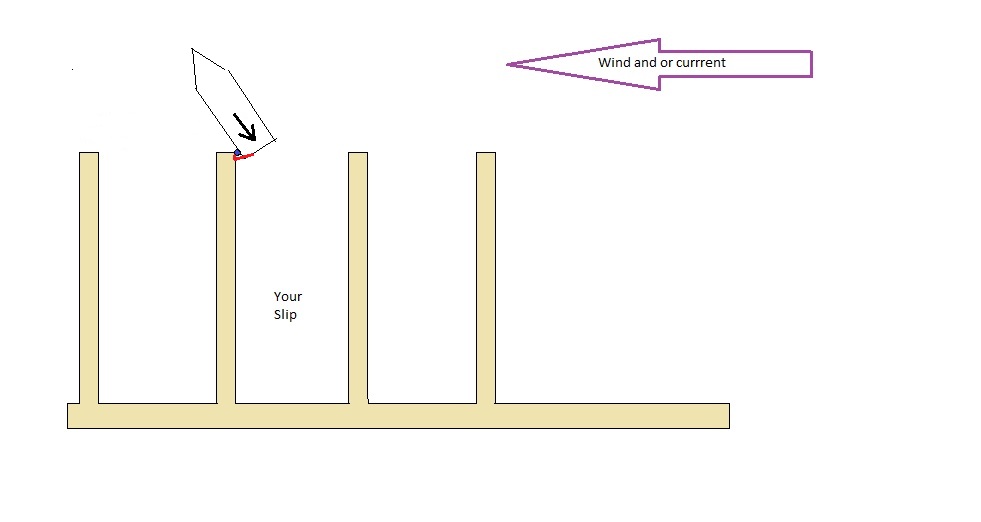

In this case you want to swing the stern out from the dock so you can back away. Take a line from a forward cleat on your boat to a midship cleat on the dock. Have your fenders set in the forward area of your port side. As you put your stbd engine into forward gear the boat will move forward until the line goes taut, then the bow will start to pivot toward the dock. When that happens the stern will swing out from the dock. When it’s far enough out from the dock that you can back away, let your deck hand know to release the line from the dock cleat, then just back away.

One big secret to making these movements work is to have good communication between you and the person who is going to handle the line. Explain to them or draw pictures to show them what you want,, then have them repeat it to you. You want to remove all possibility of a miscommunication that could damage the boat or end up with someone getting injured.

There are a lot of different ways to use spring lines to make difficult maneuvers much easier. The only limiting factor is your imagination.

Any comments? Additional suggestions? Go for it!

Many years ago a good friend of mine taught me a few tricks about making those maneuvers much easier. When most of us think of spring lines we think of the lines we use when the boat is in the slip to keep it in a certain position in the slip so the wind doesn’t move it around.

There is a whole new usage for the term “spring lines” and that’s what friend taught me. So I thought I’d share some of these tips with all of you.

First is the situation where you have to back into a slip and you’re going to have to bring the bow around against the wind, as shown below. Tie a spring line between the aft most cleat on your boat and have it looped just half way around a corner cleat on the dock. Someone needs to be standing there holding tight to the line so that on your command they can remove the line from the dock cleat. One secret to all of these spring line situations is to have adequate fenders between your boat and the dock.

As you put the boat’s stbd engine in reverse the boat will start to back up until the line goes taut. As you continue in reverse, the stern will start to pivot into the slip and the bow will come around into the wind.

The boat will continue to pivot around the corner of the dock.

As the boat starts to align with the slip, tell the person holding the line to let it come off the dock cleat and then back the boat in. You want to make sure you have plenty of fenders along your port side because the wind is going to hold it onto the dock.

The next scenario where spring lines are helpful is getting off a dock where space fore and aft is tight so you can’t go back or forward to swing out from the dock.

Here you want to swing the bow out from the dock. Put a line from a cleat near your stern to a cleat on the dock that is near the stern. Again, just go half way around the dock cleat so the line can be released in a hurry. As you go in reverse (stbd engine only) the line will go taut and the stern will pivot in toward the dock. The bow will swing out from the dock and when you feel it’s far enough out from the dock, let the person holding the line to remove it from the dock cleat so you can then go forward.

In this case you want to swing the stern out from the dock so you can back away. Take a line from a forward cleat on your boat to a midship cleat on the dock. Have your fenders set in the forward area of your port side. As you put your stbd engine into forward gear the boat will move forward until the line goes taut, then the bow will start to pivot toward the dock. When that happens the stern will swing out from the dock. When it’s far enough out from the dock that you can back away, let your deck hand know to release the line from the dock cleat, then just back away.

One big secret to making these movements work is to have good communication between you and the person who is going to handle the line. Explain to them or draw pictures to show them what you want,, then have them repeat it to you. You want to remove all possibility of a miscommunication that could damage the boat or end up with someone getting injured.

There are a lot of different ways to use spring lines to make difficult maneuvers much easier. The only limiting factor is your imagination.

Any comments? Additional suggestions? Go for it!

)

) The person on the dock is well intentioned but can really screw you up.

The person on the dock is well intentioned but can really screw you up.