Injector Testing

Injector Testing

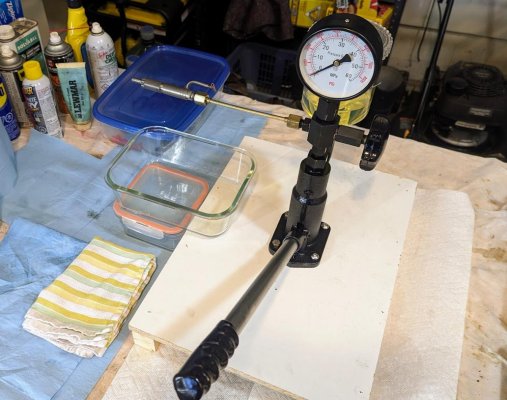

ok, i assembled all 6 injectors and tested them with the injector tester (

VEVOR 400Bar 6000PSI Diesel Fuel Injector Tester Diesel Injector Nozzle Tester with Dual Scale Gauge to Adjust Injector Nozzle Pressure and Testing Diesel Injector Nozzle Pop Pressure Tester | VEVOR US ) to decide how to proceed.

This was a bit tricky, the manual is unreadable and I could not find clear instructions on how that tester works on Youtube. I almost returned it because i thought it was broken.

so here is how it works:

1. Assembling is pretty straightforward but I unscrewed the diesel container and removed a large metal shaving from the thread. Someone on youtube recommended a full disassembly for cleaning but i did not get that far.

2. Put clear diesel in the bowl and pump it thru the unit until it's coming out clear without anything screwed to the end. Took half a cap for me.

* A large knob on the body has to be fully opened.

3. Screw your injector to the end of the testing pipe (there are 2 different connector tubes in the box), one worked for my injectors.

4. Tighten the large knob on the vertical body all the way

and then take it back a couple of degrees. - this is important, if it's too tight or too loose - you can not build pressure.

5. Now, when you pump the handle, you will be building pressure in the system until the injector pops/injects

Note the maximum pressure at which that happened. For 6LY injectors, it has to be between 290 and 300 kg/cm2 or 4120 - 4267 PSI

If they release too soon, you need to add a thicker shim, if it fires too late, you need to remove a shim.

6. Note how it releases. It's hard to explain, but it should not "spray" like a spray bottle but rather "shoot" more like a gun.

7. Check the pattern to ensure all five streams are the same and uniform.

8. Next, pump the pressure to ~300 PSI and tighten the large knob to keep the injector pressurized.

The nozzle should not leak fuel.

A few observations:

- Needle size was different in at least 2 nozzles because those needles did not fit into the other 4

- I had different sizes of shims from 0.15 to 0.30 mm in thickness.

- I found that on some injectors, shims have a chamfer and must be installed with that chamfer facing the nozzle. The manual says it could lead to damage or other problems if installed incorrectly. i could not find any chamfer on my shims but check yours just in case.

- The nozzle cup has to be tightened to a specific torque (39.2-44.1 Mm, which is 28.9 to 32.5 ft lb)

One more reminder not to mix any internal parts of those injectors when you take them apart for cleaning.

All 6 of my injectors had bad spray patterns, a few leaked and have weak long spray instead of fast fire and 4 of 6 had a wrong release pressure. Maybe that could be fixed by cleaning the nozzles some more with the nozzle cleaning wire and trying to adjust the shims.

But i was placing an order for the rest of the spare parts so i included all 6 new nozzles (they come with the needles) and 6 set of shims and will have a shop assemble them.

At least i know now for sure this expense is justified

).

).