Pack Mule

TF Site Team

- Joined

- Jan 24, 2013

- Messages

- 3,749

- Location

- USA

- Vessel Name

- Slo-Poke

- Vessel Make

- Jorgensen custom 44

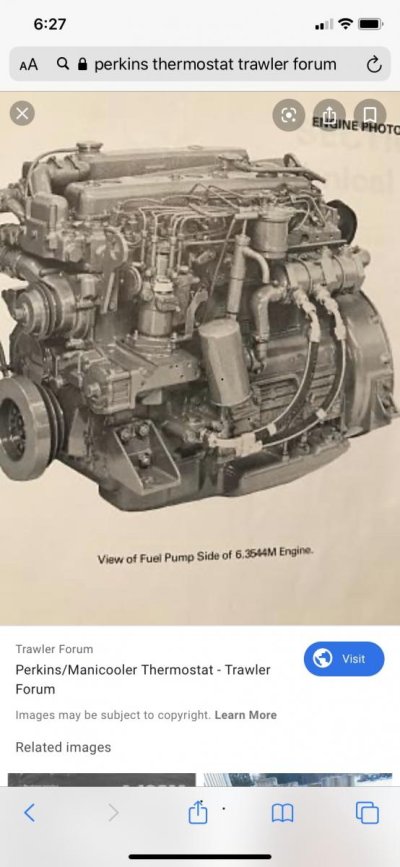

I’m in the middle of replacing my thermostats on my Perkins 6.354 na . This should be a fairly simple job right. Mine has two thermostats under the housing neck and there are three 5/16” dia bolts that hold the housing neck down. All three bolts were froze tight. I tried everything but heat. Pb blaster, Kroil penetrating oil, hand impact, battery and air impact.

I finally used a breaker bar and got one bolt out and broke the heads off the other two. After a lot of prying and more PB Blaster I was able to get the housing off. The housing was seized to the bolts. After I got the housing free and off the other two bolts came out by hand. I may need to get another housing because I buggered the bottom of mine with all the prying.

Does anyone know why this engine has two thermostats or is this normal for all Perkins? Simple job not so simple.

I finally used a breaker bar and got one bolt out and broke the heads off the other two. After a lot of prying and more PB Blaster I was able to get the housing off. The housing was seized to the bolts. After I got the housing free and off the other two bolts came out by hand. I may need to get another housing because I buggered the bottom of mine with all the prying.

Does anyone know why this engine has two thermostats or is this normal for all Perkins? Simple job not so simple.