Marco Flamingo

Guru

- Joined

- Jan 7, 2020

- Messages

- 1,111

- Location

- United States

- Vessel Name

- CHiTON

- Vessel Make

- Tung Hwa Clipper 30

Replacement should be the last choice.

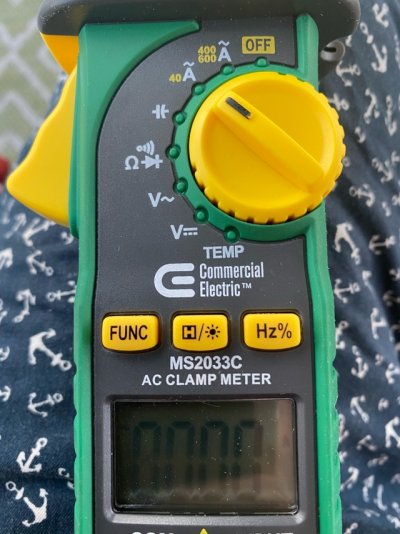

They draw lots of Amps, the Muir on my last boat drew 120A after motor rebuild and promptly fried the ammeter.

Are you running engines while you (attempt) retrieve? Anchor mfrs usually advise it.

Sounds like bad connections or a defective motor to me.

I have a brand new Muir Storm thanks to the prior owner, but he didn't install the circuit breaker. Muir says it draws 80 amps, but after installing the Muir 150A breaker that I found in a locker, it trips right when the anchor tries to make the 90 degree turn on to the pulpit. Haven't done the trouble shooting yet.

I haven't seen any mention of a circuit breaker in this thread. Is there one? If the winch is pooping out but not blowing the breaker, it isn't getting enough juice to blow it.

Hopefully, this is one of those frustrating missdirection projects. OP worked on the gears so it must be the gears. Turns out it is a corroded electrical connection that cooincidentally appeared at the same time.