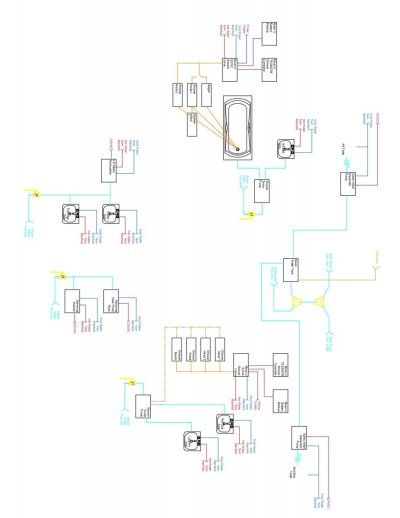

How big a boat? How many people? Planned water budget for 24 hrs? What will your peak water flows in each line? Water flow rate, length, number of bends and valves sizes lines (pressure drop calculation). What components will be operating at the same time (total flow rate required)? A larger accumulator is ok if you have the space results if less pump cycles.

Seems very complicated. Hotter tanks can be run at temps above 120 F if you have a mixing valve to control temps to a delivery temp of 120. Makes for more hot water with a smaller hot water tank.

Do you have another drawing showing all of the drain lines, black water and grey water tanks. Electrical power drawing? Number of thru hulls and overboard drains. Controlling 7 small tanks as they pump down will be a pain if you do it individually. Filling will be difficult and could take some time.

What does the mid and aft galley maid pump do. They only have a cold water supply. Just some general comments.

No idea about water usage for 24 hrs.

Peak water flows depends on the number of people, but having two bathrooms does help limit this.

The size of the boat is 65', which will be 70' with the swim platform extension.

For normal usage 4 to 6 people.

Day usage, no overnight, usage 10 people

For controlling the 7 tanks, they will be linked, and as long as the valves are all open, will operate as a single tank. The filling will operate the same way as well. Dock water will go to a deck hose opening, water will flow into a manifold, and fill up each tank.

The galley maid pumps are the macerator pumps. They require, at least to my understanding, a water line in. Technically it is supposed to be sea water, but I am using fresh water.

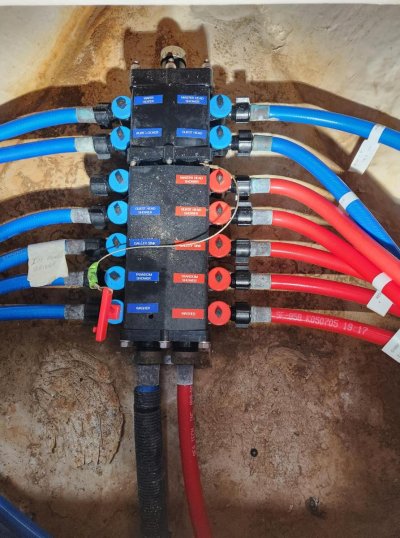

Attached is a photo of the waste system. There is no grey water tank, only a black water tank, which is overly large. It was a microphor waste system. It will be just a holding tank like a normal system. I thought about trying to get it out of the boat, but it is big pain in the butt.