You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cold Plate Conversion

- Thread starter hmason

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

ofer

Guru

- Joined

- Apr 10, 2020

- Messages

- 530

- Location

- USA

- Vessel Name

- Unicorn

- Vessel Make

- 1970 50' DEFEVER OFFSHORE CRUISER Timber

To check how good the insulation is in your box , purchase a block of ice and stick it inside. Do not open the box for 24 hours then weigh the ice, close the door and wait 24 or 48 hours.

Then weight whats left of the block of ice.

IF you melted less than 5 lbs per day electric refrigeration will work.

I tried this in Alaska during winter, ice block did not melt at all. I have really good insulation.

Cigatoo

Guru

Sure, I’d be happy to share my work, but I’ll need to explain a little about my specific GB configuration for it to make sense…. In my GB I have the freezer aft the port door and the fridge forward (the port door). I do not have an L configuration on my galley cabinetry. I also wanted to maintain the teak wood doors with the temp gauges that were delivered with the boat when it was new. Essential I wanted the salon to look “stock”.

My fridge/freezer system was completely operable when I started this modification. The main reason I undertook this project was my 3000w true sine wave inverter did not have the surge capacity to “start” the Grunert compressor, therefore, the only way I could “refreeze” or “recover” the cold plates would be on generator or shore power. My system would take more than a few hours of generator run time before the fridge/freezer temps to stay cool enough for me. After running longer voyages the heat from the engine room would cause me to run the generator for longer periods of time than I wanted to run to allow the fridge/freezer temps to recover. Plugging into shore power after voyages wasn’t an issue, but not every voyage of mine ends up in a marina.

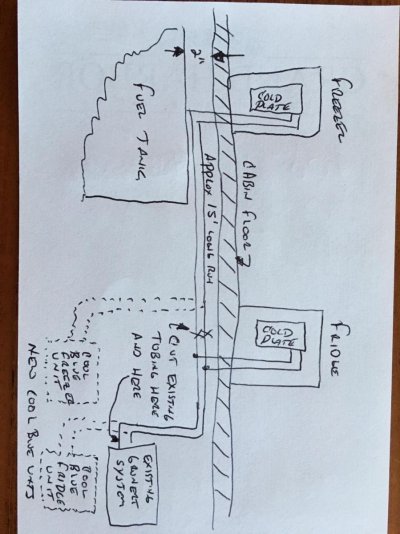

I’m going to make the assumption that if you’re about to undertake a conversion you have a knowledge on how the Grunert system is configured with a single compressor and the solenoid valves/tubing to jointly run the system. Converting to a CoolBlue system required two compressors to make the system function. Specifically, one CoolBlue unit for the fridge and one CoolBlue unit for the freezer. In the completed form of my upgrade, the freezer and fridge both run independently now.

CoolBlue sells their systems as a set, meaning the cold plates, the copper line sets and the compressor, all recharged and ready to install, plug and play. Had I had access to all the required areas to install the CoolBlue systems, the two sets of CoolBlue systems would have been an easy install. In my GB’s configuration, cold plate mounting in the fridge is easy, replacing the Grunert compressor with the two CoolBlue compressors is easy, but the supply/return tubing, that’s different. Access to the bottom of the fridge, in the engine room, is not a problem for the tubing runs. However, the freezer is directly above the port fuel tank and there’s only about an inch of space rendering it completely inaccessible.

My solution was to cut the existing tubing below the refrigerator and splice in the new CoolBlue units into each tubing pairs (one pair for the fridge and one pair for the freezer) and leaving everything on the cold box side of both of those splices as original from GB. I didn’t touch anything after the splice, meaning the inaccessible freezer tubing, each temperature controls, each TXV valve, each cold plate…. All I had to do is run new 12V DC wiring from my house bank with the associated breakers, install the two CoolBlue compressors and splice the tubing together (re the sketch). I did have to vacuum down each of the systems after the the configuration was complete, and bring the 134 charge to proper levels.

I did not purchase CoolBlue’s cold plates or copper line sets (I did need to buy an adapter to attach the vacuum pump). I did not remove the cold plates at all.

I really like this system, and it has reduced my boating issues significantly while maintaining that gorgeous stock look.

View attachment 120594

Thank you. Sounds like just what is needed for our GB 36. Single unit only as we have no freezer. I also want to keep everything stock.

Choices

Guru

- Joined

- Apr 16, 2018

- Messages

- 899

- Location

- Montgomery, Tx

- Vessel Name

- Choices

- Vessel Make

- 36 Grand Banks Europa

GB built the boxes hell for stout.

The stainless interior was placed in a fiberglass tub, on it's back, and foam was poured around it.

My guess is 2-3" for the frig, 3-4" for the freezer.

The entire tub is then screwed to the inside cabinet front, and the cabinet built around it.

So to remove a tub, you must take the stainless interior apart at the seams with a chisel, then cut out the fiberglass tub.

A major pain.

We used Vitrifrigo components and pulled the cold plate guts out and replaced with totally new in the existing stainless box and original doors.

The compressors are mounted in the lazarette against the firewall, and the area stays cool since the bilge is in contact with sea water.

Super clean installation, routed tubing the same way.

I considered reusing the cold plate but why? My system runs continually off 12vdc batteries. The draw is tiny. When motoring it is insignificant. My guess is it could go

a week before needing to parallel batteries.

I installed both units in a day. While at it I retrimmed the freezer hatch.

Cost almost exactly $2k.

The stainless interior was placed in a fiberglass tub, on it's back, and foam was poured around it.

My guess is 2-3" for the frig, 3-4" for the freezer.

The entire tub is then screwed to the inside cabinet front, and the cabinet built around it.

So to remove a tub, you must take the stainless interior apart at the seams with a chisel, then cut out the fiberglass tub.

A major pain.

We used Vitrifrigo components and pulled the cold plate guts out and replaced with totally new in the existing stainless box and original doors.

The compressors are mounted in the lazarette against the firewall, and the area stays cool since the bilge is in contact with sea water.

Super clean installation, routed tubing the same way.

I considered reusing the cold plate but why? My system runs continually off 12vdc batteries. The draw is tiny. When motoring it is insignificant. My guess is it could go

a week before needing to parallel batteries.

I installed both units in a day. While at it I retrimmed the freezer hatch.

Cost almost exactly $2k.

Last edited:

SteveK

Guru

- Joined

- Jul 5, 2019

- Messages

- 5,092

- Location

- Gulf Isalnds BC canada

- Vessel Name

- Sea Sanctuary

- Vessel Make

- Bayliner 4588

You did it all wrong. Being north of the 49th you have to put a pot of boiling water in box, check temp in 24 hours and if it did not go down more than 50* you have good insulation.I tried this in Alaska during winter, ice block did not melt at all. I have really good insulation.

Similar threads

- Replies

- 15

- Views

- 2K

- Replies

- 0

- Views

- 515

- Locked

- Replies

- 4

- Views

- 2K

Latest posts

-

-

-

Fixing boats in Exotic Places - are new boats really that bad?

- Latest: Hippocampus

-

-

-

-

-