Alisske

Senior Member

I had gotten a new “to me” boat (26 downeast single screw diesel) about 10 years back. First order if things was to take care of the engine and emergency systems. Spent a lot of time figuring out bilge pump set ups and capacity as well as scuppers etc…. I take the boat on fairly long trips over open waters. .

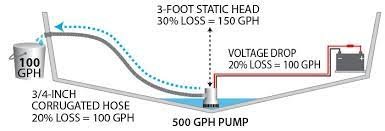

One of the main things I wanted to understand was “when is a hole too big?” to be managed by pumps? I spent a good amount of money setting up two substantial pumps (2) 10 GPM electric utility puppy pumps and (1) 1.25 inch main motor driven Jabsco pump at 60 GPM. I chose not to have a “Y” set up for my raw water pump since the last thing I'm gonna be doing is messing with my motor during an emergency (some folks may disagree, but thats my belief)

For a boat my size and was able to shed about 80 gallons a minute.

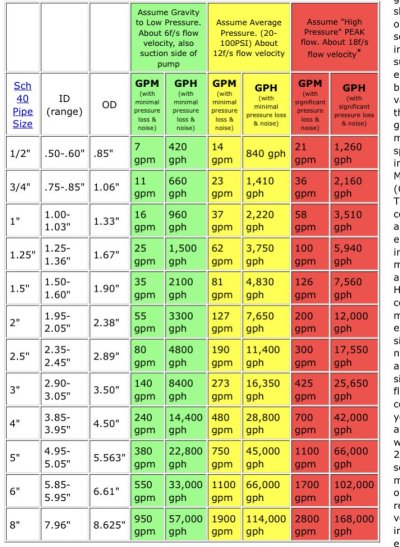

The chart below is typical water flows for pipes and served as my reference for calculating how much water can enter a boat for a hole diameter size. Now i know water flow dynamics is a tricky beast (depending on depth in water, run and height of DC hoses, time a hole can spend out of the water in wave actions etc…).. BUT, the flow rates are astonishing. For my boat, I assume anything over a 1.5 inch hole and it is a matter of time before I sink (unless repaired).

Now before everyone starts talking about repairing, there may not be access, or you cannot locate the hole, etc….

I feel it’s important to know these things in advance because it will dictate the response to the emergency.

I just wanted to get other folks opinions. I see plenty of the trawlers have trash pumps set up (which i think is awesome).

One of the main things I wanted to understand was “when is a hole too big?” to be managed by pumps? I spent a good amount of money setting up two substantial pumps (2) 10 GPM electric utility puppy pumps and (1) 1.25 inch main motor driven Jabsco pump at 60 GPM. I chose not to have a “Y” set up for my raw water pump since the last thing I'm gonna be doing is messing with my motor during an emergency (some folks may disagree, but thats my belief)

For a boat my size and was able to shed about 80 gallons a minute.

The chart below is typical water flows for pipes and served as my reference for calculating how much water can enter a boat for a hole diameter size. Now i know water flow dynamics is a tricky beast (depending on depth in water, run and height of DC hoses, time a hole can spend out of the water in wave actions etc…).. BUT, the flow rates are astonishing. For my boat, I assume anything over a 1.5 inch hole and it is a matter of time before I sink (unless repaired).

Now before everyone starts talking about repairing, there may not be access, or you cannot locate the hole, etc….

I feel it’s important to know these things in advance because it will dictate the response to the emergency.

I just wanted to get other folks opinions. I see plenty of the trawlers have trash pumps set up (which i think is awesome).