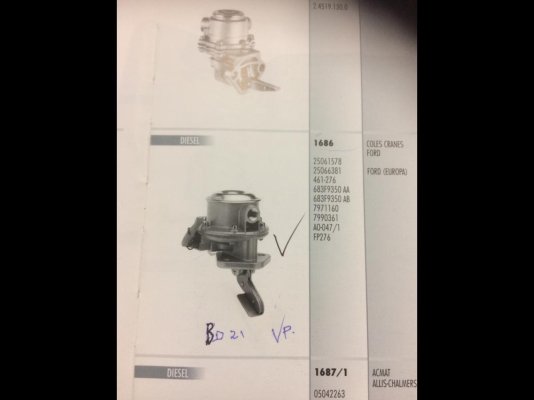

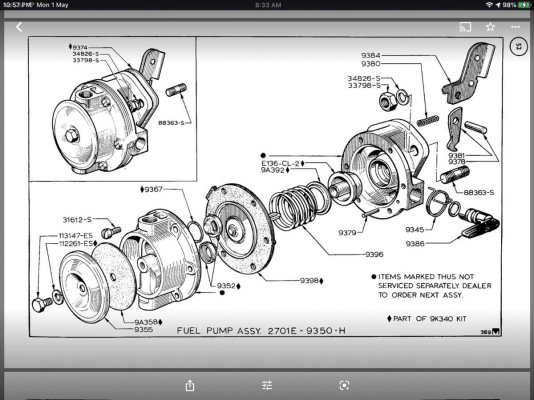

Okay. For whatever it is worth, I think the lifter pump you just put in is the correct one for the engine. I'm surprised the short stubby one worked, but I don't know the internal geometry.

Just to check the obvious....have you checked your fuel supply and return valves? Are they set correctly? Are they operating correctly?

So, if I understand correctly, the boat is presently on the hard, this issue is occuring while testing on the hard, and it continued to occur after the replacement of the lift pump?

Does the engine start right back up after it occurs?

While running at lower RPMs, what does the smoke look like?

What do you mean when you write that it "fades" as it approaches 2000 rpm? RPM instability like surging? Very little RPM change for throttle increase? Can you describe what you are observing in as much detail as possible.

Assuming it runs indefinitely while at lower RPMs, suffers increasing RPM instability as it approaches 2000rpm, and then stalls out at 2000rpm, this is almost certainly a fuel system issue.

My first suspect is fuel starvation originating in the low pressure part of the fuel system. What you are describing is usually the flow rate of the fuel from the low pressure system being insufficient to fully supply the injector pump when it needs to supply more fuel quickly for higher throttle settings. This usually shows itself as the engine doing just fine until a throttle setting where the demand of the high pressure injector pump starts to equal the supply by the low pressure system. At that point it doesn't always get what it needs. The governor calls for more fuel, and now sometimes it matters very little because the fuel isn't there and sometimes it gets a good gup and the engine and RPMs surge. So, we've gone from a smooth running engine to surging with relatively little change in throttle. Then we just stall out. It surges forward then doesn't get enough fuel to keep going.

If this isn't it, I then start to suspect the high pressure part of the fuel system: The injectors and the injector pump. This type of problem is often accompanied slicking of the water with fuel (you may not see that on the hard) by a smoking issue, in particular copious white diesel smoke or even an, even at low throttle settings. In particular, if there isn't a smoke problem, I doubt there is a problem on the high pressure side. And, even if there is a smoke problem, it could still be the low pressure side -- not enough fuel hurts the spray pattern leaving drop of fuel not a mist.

The injectors usually run better at high throttle settings than low throttle settings. So, if it is running smoothly at low throttle settings and only gets worse with high throttle, injectors are not usually my 1st thought. Also, there are 6 of them, so it is unlikely all 6 are critically bad. So, the engine usually runs rough due to the unevenness.

One thing one can do is, with the engine at a fast idle, is to open (loosen a lot) the supply (not return) line to each fuel injector one at a time. This will make a mess. Fuel will spill so have a rag ready. What you should hear is the engine run notable worse. Then tighten it up. If one injector makes a lot less of a difference than the others, or no difference at all, it is probably bad. You can also just pull all of the injectors and have them tested at an injector shop. They'll usually "pop test" them and check their spray pattern visually for free. Injectors aren't my first guess, even on the high pressure side, but they are easy to test, so, I'd sure open and close each line and see what happens. Why not? It takes 15 minutes start to finish.

It could also be the injector pump, but that is expensive to rebuild. And, I'd hate to do it unless it really needed it. The best I know to do is to rule it in by rulin everything else out. If, for example, an injector seems bad, I swap it with another injector. If the problem follows the injector, it is the injector. If it stays with the cylinder, it might well be the pump. Depending upon how the pump fails, it could impact one injector or all of them. But, pumps failing to the point of stalling at modest RPM settings are somewhat rarer than low-pressure fuel system problems doing the same. In general, pumps will misbehave with things smoking badly and/or running rough before they get there. By contrast, obstructions on the low pressure side, or a failure in the low pressure pump, can develop quickly.

You can disconnect the hose from the lift pump and attach an electric transfer or lifter pump and long hose to it and try pumping fuel out of the tank, through the primary filter and all the hoses to this point....and back into the tank via the fill. If you get a good flow, things are probably good. If you see lines collapsing or don't get a good flow, there is probably a problem to this point.

You can then reconnect the hose at the pump and disconnect the other end of it. Put it into a 5 gallon bucket filled ~80% with fuel. See how the engine runs from the bucket or portable tank. This is another way to check for a problem from the tank to this point.

You can also use the lifter pump in-line with the mechanical pump, so that if the mechanical pump isn't doing its job, the electric pump pushes through it and gets the

injector pump the fuel and see what happens.

If it isn't from the fuel tank to the engine block, and isn't the injectors, and doesn't seem like the injector pump....it could be the 2ndary on-engine fuel filter. Pull it off and check around the housing. Make sure it is all clear. Replace it.

The Lehman normally uses, I think, hard lines for the fuel filters. Disconnect them and check them for obstructions. Look for any broken gasket bits, etc, in the lines.

If it really doesn't seem like hoses, either fuel filter, any of the hard or soft fuel lines, or the injector pump, there is a small chance it is a return path obstruction. The most likely culprit here is a closed or mis-set fuel return valve. The next most likely culprit is a bad one-way (non-return) valve going to or at the tank.

Get ready for a mess. Disconnect the return line to the tank from the end of the return lineset. Try blowing through it. Then, try to get a hose around or attached to where the hose should be on the engine and direct it to a bucket. See if the engine runs better returning to the bucket than through the line.

Finally, pull the injector pump and all of the injectors and take them to a shop.

Basically, check filters and hard lines installation (easy). Check injectors (easy). Check fuel flow to injector pump (temp source and hose). Check lifter pump (push through with electric). Check return resistance. Pull injector and take to shop.

I'm not there to see what is going on or to look over things. So, this might not be worth much. But, it is the best I've got sitting here. Let us know what you learn and we can all put our heads together.